33. Polymers II (Intro to Solid-State Chemistry)

TLDRThis lecture delves into the world of polymers, exploring their formation through radical initiation and condensation polymerization. It highlights the significance of monomers, molecular weight, and the distribution in determining polymer properties. The instructor discusses various factors like branching, tacticity, and cross-linking that can alter polymer characteristics, leading to diverse applications. The session also touches on the environmental impact of polymers and the challenges of recycling thermosets versus thermoplastics, hinting at future discussions on eco-friendly polymers.

Takeaways

- 📚 The lecture focuses on polymers, their formation through radical initiation and condensation polymerization, and their properties.

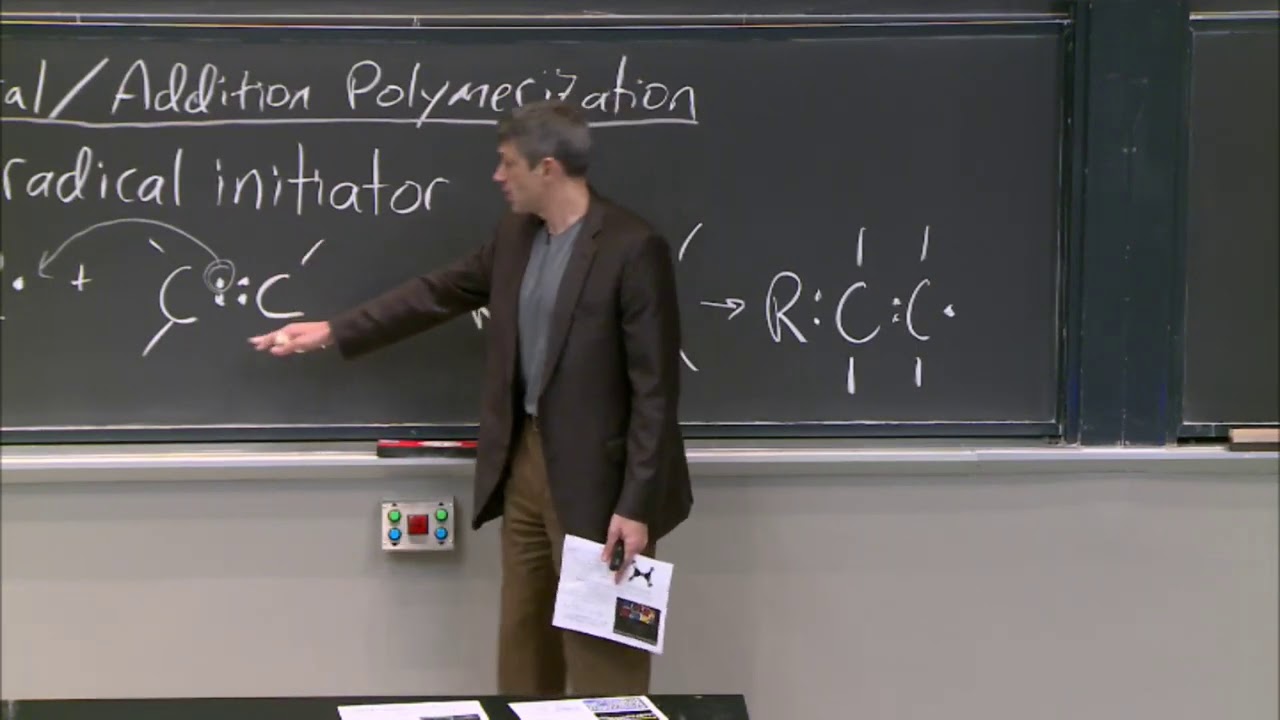

- 🔍 Radical initiation involves a chain reaction started by a radical initiator, leading to chain polymerization, also known as addition polymerization.

- 🔗 Condensation polymerization is characterized by the reaction of two different monomers with end groups that form a bond and release byproducts like water, HCl, or NH3.

- 🧬 The monomer is the repeating unit in a polymer and is crucial in determining the polymer's characteristics.

- 🔢 Molecular weight and degree of polymerization are significant as they indicate the size and number of monomer units in a polymer chain.

- 🔄 Polymers can have a distribution of molecular weights, which can affect their properties and applications.

- 👆 The properties of polymers can be controlled by the monomer type, molecular weight, intermolecular forces, and the polymer's physical structure.

- 🌐 Intermolecular forces (IMFs) such as London dispersion forces and hydrogen bonds play a role in the strength and behavior of polymers.

- 💧 Differences in density and crystallinity, influenced by the polymer's processing and temperature, lead to variations in properties.

- 🌿 The physical structure of the polymer chain, including branching and tacticity, affects how the polymer can crystallize and its overall properties.

- 🔗 Cross-linking is a critical method for engineering polymer properties by creating covalent or other types of bonds between polymer chains.

Q & A

What are the two main methods discussed for the formation of polymers?

-The two main methods discussed for the formation of polymers are radical initiation, which involves chain polymerization or addition polymerization, and condensation polymerization, which involves the reaction of two different monomers with end groups that can form a bond and release a small molecule like water.

What is the significance of the double bond in the monomer during the polymerization process?

-The double bond in the monomer is significant because it allows for the addition of more monomers, facilitating the chain reaction in radical initiation or the formation of a bond with another monomer in condensation polymerization. It is a key site for the polymerization reaction to occur.

How does the molecular weight of a polymer influence its properties?

-The molecular weight of a polymer, which is an average measure of the mass of its molecules, influences its properties such as strength and toughness. Higher molecular weight polymers typically have longer chains, which can lead to increased strength due to more covalent bonds in the backbone.

What is meant by the term 'degree of polymerization'?

-The term 'degree of polymerization' refers to the number of monomer units that are joined together to form a polymer chain. It is a measure of how many 'mers' are in a single strand of the polymer.

Why is the distribution of molecular weights important in polymer synthesis?

-The distribution of molecular weights is important in polymer synthesis because it affects the physical properties of the polymer. A broad distribution can result in a range of different properties within the same material, while a narrow distribution can lead to more uniform properties.

What are intermolecular forces (IMFs) and how do they apply to polymers?

-Intermolecular forces (IMFs) are the forces that mediate interaction between molecules, including van der Waals forces, hydrogen bonding, and dipole-dipole interactions. They apply to polymers by influencing the strength, flexibility, and other physical properties of the material, depending on the nature of the monomers and their arrangement in the polymer chain.

How does the presence of hydrogen bonding in polyvinyl alcohol make it stronger mechanically compared to other polymers?

-The presence of hydrogen bonding in polyvinyl alcohol allows for stronger interactions between the polymer chains compared to van der Waals forces alone. Hydrogen bonds are stronger than typical London dispersion forces, leading to a mechanically stronger polymer.

What factors influence the crystallinity and density of a polymer?

-Factors that influence the crystallinity and density of a polymer include the processing conditions such as cooling rate, the molecular structure of the polymer, and the presence of cross-linking. The ability of the polymer chains to align and form an ordered, repeating structure contributes to crystallinity, while the overall packing of the chains affects density.

How does the physical structure of a polymer chain, such as branching or tacticity, affect the properties of the polymer?

-The physical structure of a polymer chain significantly affects its properties. Branching can disrupt the regular packing of chains, potentially reducing crystallinity and strength. Tacticity, which refers to the arrangement of side groups along the chain, can influence the ability of chains to align and pack closely, affecting crystallinity, strength, and melting point.

What is cross-linking in polymers and why is it important for engineering the properties of polymers?

-Cross-linking in polymers is the process of forming covalent bonds or other strong linkages between different polymer chains. It is important for engineering the properties of polymers because it can greatly enhance the strength, elasticity, and thermal stability of the material. Cross-linking can also affect the material's response to stress over time, influencing its viscoelastic properties.

How did Charles Goodyear's accidental discovery of vulcanization change the properties of natural rubber?

-Charles Goodyear's accidental discovery of vulcanization involved heating natural rubber with sulfur, which led to the formation of covalent cross-links between the polyisoprene chains. This process transformed the soft, moldable natural rubber into a material with controlled flexibility and hardness, making it more durable and resistant to melting or sticking under heat and pressure.

What is the difference between thermosets and thermoplastics in terms of their cross-linking and recyclability?

-Thermosets are highly cross-linked polymers that, once set, cannot be melted down and reshaped, making them difficult to recycle. They maintain their shape and integrity when heated due to the extensive cross-linking. Thermoplastics, on the other hand, have less or no cross-linking, allowing them to be heated and reshaped multiple times. This makes thermoplastics more easily recyclable, but they may not possess the same mechanical properties as thermosets.

Why is the concept of viscoelasticity important in understanding the behavior of polymers?

-Viscoelasticity is important in understanding the behavior of polymers because it describes the combination of both viscous and elastic properties in a material. Polymers can exhibit both liquid-like flow and solid-like elastic recovery, depending on factors such as the rate of deformation and temperature. This concept helps explain how polymers can be both strong and flexible, and how their properties can be tuned through manipulation of cross-linking and molecular structure.

What is the environmental concern associated with cross-linking in polymers, and how might it be addressed?

-The environmental concern associated with cross-linking in polymers is related to the difficulty in recycling thermoset materials due to their extensive cross-linking. To address this, researchers are exploring reversible cross-linking chemistries that could allow for the degradation and reuse of polymers, offering a more environmentally friendly approach to plastic production and waste management.

Outlines

📚 Introduction to Polymers and Lecture Overview

The lecture begins with an introduction to polymers, which are large molecules composed of repeating units called monomers. The instructor emphasizes the importance of polymers as the topic of both the lecture and an upcoming quiz. The lecture's agenda includes a review of the methods for creating polymers, specifically radical initiation and condensation polymerization, which were covered in a previous session. The instructor also mentions the significance of double bonds in monomers for the polymerization process and hints at discussing the properties and manipulation of polymers in the current session.

🔍 The Role of Monomer and Molecular Weight in Polymer Properties

This paragraph delves into the factors that dictate the properties of polymers, starting with the monomer itself—the basic repeating unit in a polymer chain. The instructor discusses how variations in the monomer can lead to different types of polymers, such as polyethylene or those with added benzene rings. Molecular weight is also highlighted as a critical factor, affecting the degree of polymerization and the physical properties of the polymer. The concept of an average molecular weight is introduced to account for the variability in polymer chain lengths, which can range from hundreds to millions of monomer units.

🔬 Exploring Polymer Strength and Intermolecular Forces

The instructor explores the mechanical strength of different polymers, focusing on the intermolecular forces (IMFs) that contribute to their stability and integrity. By comparing polyethylene, polystyrene, and polyvinyl alcohol, the lecture illustrates how the presence of hydrogen bonds in polyvinyl alcohol makes it mechanically stronger than polymers that rely solely on London dispersion forces. The paragraph also introduces the concept of macromolecules and their behavior in different states, such as crystalline and amorphous, which can be influenced by factors like molecular weight and chemical bonding.

🌡️ Density, Crystallinity, and Polymer Properties

This section discusses how the density and crystallinity of a polymer can significantly affect its properties. The instructor uses the example of polystyrene to demonstrate how different forms of the same polymer can have varying properties based on their density. The concepts of crystalline regions, where polymer chains are ordered, and amorphous regions, where they are disordered, are introduced. The paragraph explains how processing conditions, such as cooling rate, can influence the degree of crystallinity and, consequently, the material's properties.

🌱 Branching and tacticity: Controlling Polymer Structure

The lecture continues with an exploration of how the physical structure of polymer chains can be manipulated to control polymer properties. Two key concepts are introduced: branching, which involves the growth of side chains from the main polymer backbone, and tacticity, which refers to the spatial arrangement of side groups on the polymer chain. The instructor explains how controlling branching can influence crystallinity and how tacticity can affect the polymer's ability to pack closely together, both of which have implications for the material's strength and flexibility.

🔗 The Impact of Cross-linking on Polymer Properties

Cross-linking is introduced as a method for engineering the properties of polymers by creating covalent bonds between different polymer chains. The instructor explains how cross-linking can significantly enhance the strength and stability of a material. The paragraph provides an example of nylon, a polyamide, where amide bonds can lead to natural cross-linking between chains, contributing to the material's properties. The concept of cross-linking is positioned as a critical tool in the design and engineering of polymers with specific characteristics.

👢 The Historical Evolution of Rubber and Vulcanization

This paragraph delves into the history of rubber, highlighting its initial uses by the Mayans and the challenges associated with its instability at high temperatures. The story of Charles Goodyear's accidental discovery of vulcanization is recounted, illustrating how the process of adding sulfur to rubber transforms its properties, making it more stable and useful. The role of double bonds in the vulcanization process is emphasized, as they provide sites for the formation of covalent bonds with sulfur, leading to cross-linking between rubber strands.

🔗 Cross-linking Mechanisms and Their Effects on Material Properties

The lecture explains the different mechanisms of cross-linking, including covalent bonding, hydrogen bonding, and ionic interactions, and how they contribute to the material's properties. The paragraph discusses the balance between the strength provided by cross-linking and the flexibility of the material. It also introduces the concept of viscoelasticity, where materials exhibit both viscous and elastic characteristics, and how this is influenced by the rate of cross-link formation and destruction.

🎨 Customizing Polymer Properties Through Cross-linking

The instructor discusses how cross-linking can be used to customize the properties of polymers, such as their elasticity, hardness, and flexibility. The paragraph provides examples of how cross-linkers can be used in实践活动, such as the creation of slime, and how the properties of the material change with the addition of more cross-linkers. The lecture also touches on the challenges of recycling cross-linked polymers, known as thermosets, due to their stability and resistance to melting.

🌿 Environmental Considerations in Polymer Design

The final paragraph addresses the environmental implications of polymer design, particularly the challenges associated with recycling cross-linked polymers. The instructor introduces the concepts of thermosets and thermoplastics, explaining their respective properties and recyclability. The paragraph concludes with a forward-looking statement about the potential for developing reversible cross-linking chemistries that could allow for more sustainable and environmentally friendly plastics.

Mindmap

Keywords

💡Polymers

💡Chain Polymerization

💡Condensation Polymerization

💡Molecular Weight

💡Density and Crystallinity

💡Branching

💡Tacticity

💡Cross-linking

💡Vulcanization

💡Thermoset and Thermoplastic

Highlights

Introduction to polymers as the main topic for the lecture and quiz.

Explanation of two methods for creating polymers: radical initiation and condensation polymerization.

Discussion on the importance of double bonds in the polymerization process.

Clarification on the difference between addition polymerization and condensation polymerization.

The role of monomers in determining the properties of polymers.

Impact of molecular weight and degree of polymerization on polymer properties.

Introduction of the concept of polymer distribution and its significance.

How intermolecular forces influence the mechanical strength of polymers.

Illustration of the difference in strength between polyethylene, polystyrene, and polyvinyl alcohol due to intermolecular forces.

The influence of density and crystallinity on the properties of polymers.

How processing conditions can affect the crystallinity and density of polymers.

Differentiation between LDPE and HDPE and their distinct properties.

Introduction to the concept of branching in polymer chains and its effect on crystallinity.

Explanation of tacticity and its impact on the physical structure and properties of polymers.

The significance of cross-linking in engineering the properties of polymers.

Charles Goodyear's accidental discovery of vulcanization and its effect on rubber properties.

The role of cross-linking in creating elastomers and viscoelastic materials.

Discussion on the environmental implications of thermosets and thermoplastics in relation to recycling.

Transcripts

Browse More Related Video

34. Introduction to Organic Chemistry (Intro to Solid-State Chemistry)

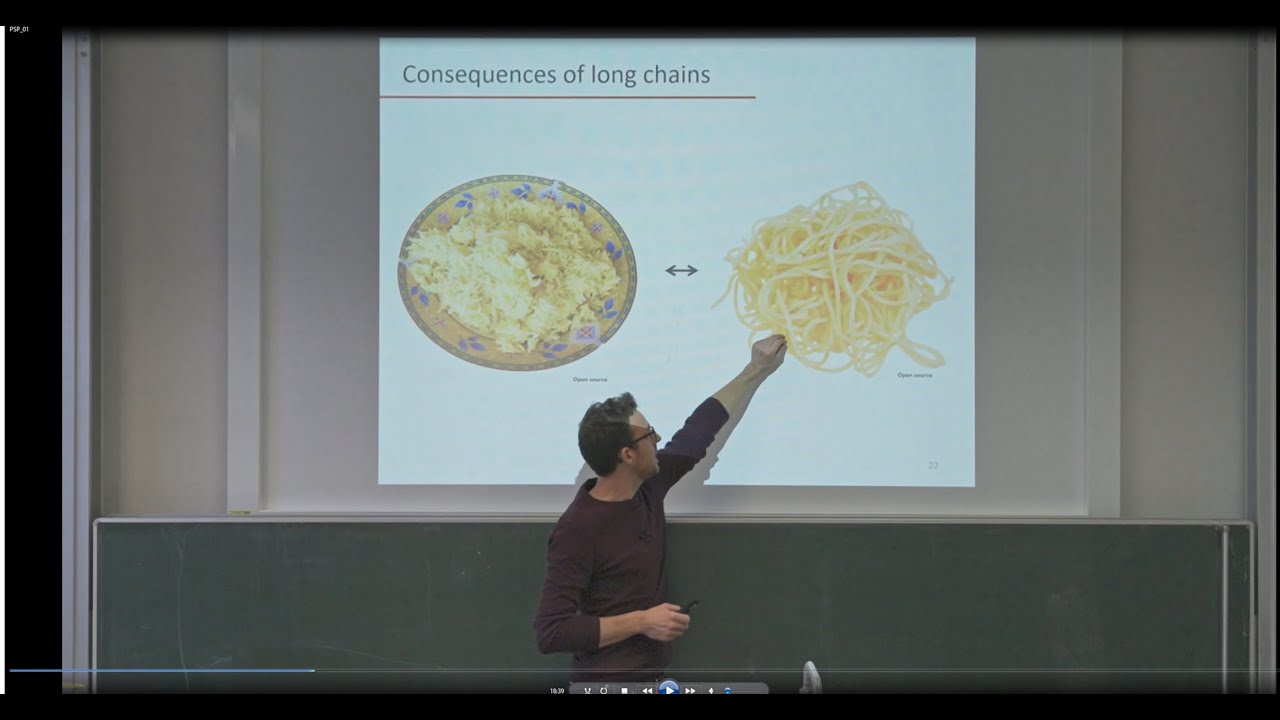

Polymer Science and Processing 01: Introduction

Polymer Chemistry: Crash Course Organic Chemistry #35

32. Polymers I (Intro to Solid-State Chemistry)

Uses Of Polymers | Organic Chemistry | Chemistry | FuseSchool

Polymer | polyethene | types of polyethene | engineering chemistry | mohan dangi | RGPV | UPTU

5.0 / 5 (0 votes)

Thanks for rating: