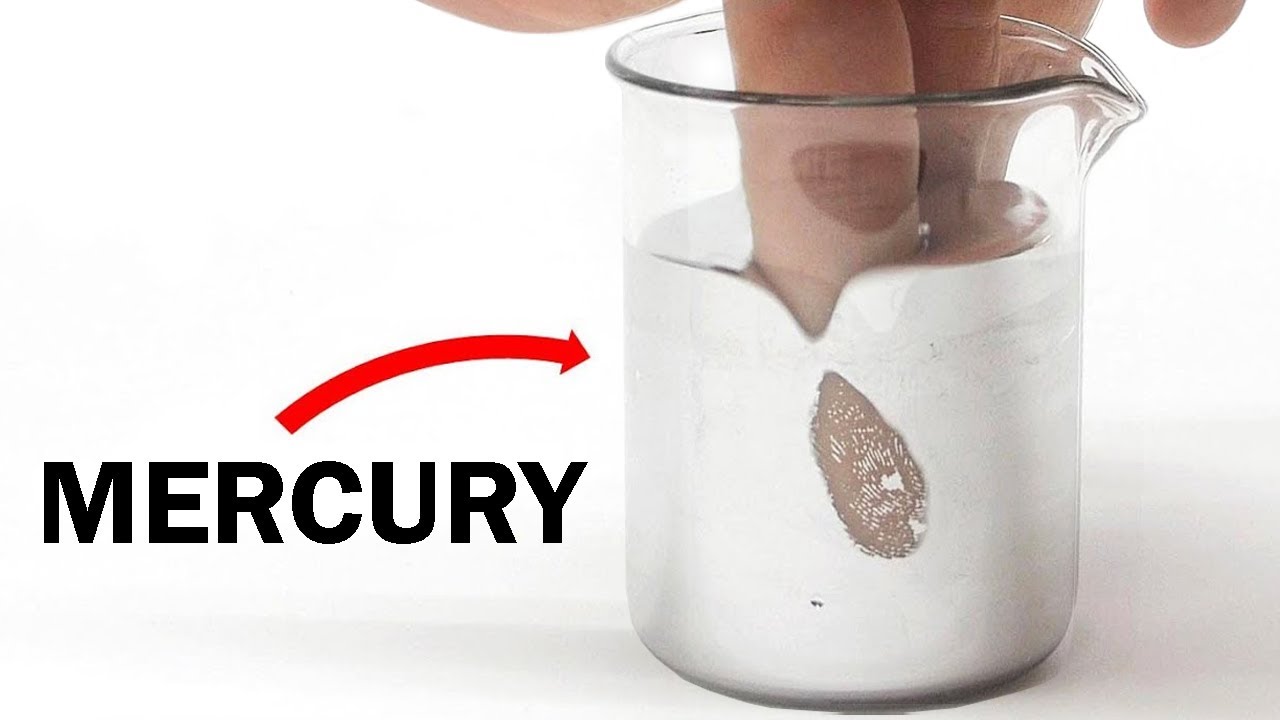

Making Mercury (Part 1)

TLDRThe video script presents a detailed account of extracting mercury from mercury sulfide, commonly known as cinnabar. It describes two primary forms of mercury sulfide found in nature: the red alpha form, historically used as a pigment called vermilion, and the less common black beta form. The process of extracting mercury involves heating the sulfide in the presence of oxygen or using a chemical reduction method, with the latter being chosen for safety reasons. The chemical method involves creating a polysulfide solution and adding aluminum to reduce the mercury sulfide to metallic mercury. The resulting mercury is then washed to remove impurities using potassium permanganate and nitric acid. The video concludes with the successful extraction of 26 grams of mercury and a discussion on safely handling and storing the metal. Additionally, the script mentions a giveaway for subscribers and followers, emphasizing engagement with the channel.

Takeaways

- 🌋 Mercury sulfide, also known as cinnabar, is the most common natural form of mercury and exists in two major crystalline forms: alpha (red) and beta (black).

- 🎨 Historically, red cinnabar was used as a pigment called vermilion in paints, cosmetics, and Chinese lacquerware, but due to its toxicity, it has been largely replaced by synthetic pigments.

- 🔥 The alpha form of mercury sulfide can be converted to the red form by heating it above 400 °C and then allowing it to cool.

- ⚗️ Mercury can be extracted from mercury sulfide through two primary methods: thermal decomposition in the presence of oxygen and chemical reduction.

- 💨 The thermal method involves heating mercury sulfide to produce metallic mercury and sulfur dioxide gas, but it can produce hazardous mercury vapor.

- 🧪 The chemical method is considered safer as it does not produce mercury vapor, but it generates mercury-contaminated waste that requires proper disposal.

- 🔑 A specific chemical process described in the script uses a polysulfide solution made from sodium hydroxide and sulfur to reduce mercury sulfide back to metallic mercury.

- ♻️ The process of extracting mercury from waste material results in a relatively pure form of the metal, which can be further cleaned using potassium permanganate and nitric acid.

- 📉 The final yield of mercury from the described process was 26 grams, suggesting that much of the initial waste was non-mercury material like silica gel and celite.

- 🚮 Proper storage and disposal of mercury and its waste products are crucial due to the potential environmental and health hazards posed by mercury contamination.

- 🔍 The quality of the final mercury product depends on the purity of the original mercury sulfide source, with waste material generally being purer than naturally occurring cinnabar.

- 🏆 The script also mentions a giveaway involving NileRed beakers and keychains as a promotional activity for the channel.

Q & A

What is the most common form of mercury found in nature?

-The most common form of mercury found in nature is mercury sulfide, also known as cinnabar.

What are the two major forms of mercury sulfide?

-The two major forms of mercury sulfide are the alpha form, which is the most common and has a strong red color, and the beta form, also known as meta-cinnabar, which is rarer and less visually appealing.

Why has the use of vermilion, a pigment derived from cinnabar, been phased out?

-The use of vermilion has been phased out due to toxicity issues associated with mercury, and it has been replaced by safer synthetic pigments.

How can mercury metal be extracted from mercury sulfide?

-Mercury metal can be extracted from mercury sulfide through two major processes: thermally, by heating the sulfide in the presence of oxygen, and chemically, by reducing the mercury sulfide back to the metal using a solution and other chemicals.

What is the general formula for polysulfides?

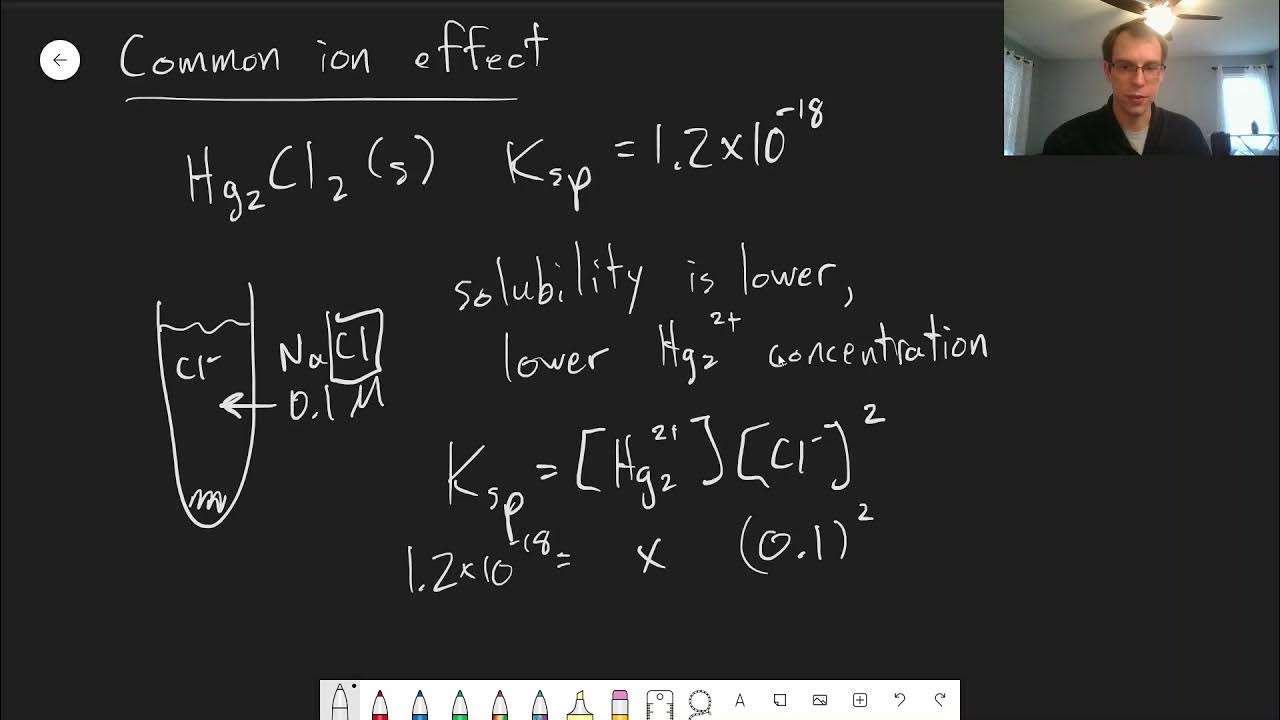

-The general formula for polysulfides is Na2Sx, where x can range from 2 to 5 sulfur atoms.

How does the chemical method of extracting mercury metal differ from the thermal method in terms of safety?

-The chemical method is safer than the thermal method because it does not produce mercury vapor, which can be quite dangerous. However, it generates more mercury-contaminated waste that needs to be managed.

What is the process of making a polysulfide solution?

-The process of making a polysulfide solution involves first creating a strong sodium hydroxide solution, then adding sulfur to it. The reaction produces mostly sodium sulfide and some polysulfides, which give the solution a dark red color.

What is the role of sodium hydroxide in the polysulfide solution?

-Sodium hydroxide is used in excess to prevent the hydrolysis of sodium sulfide and other polysulfides. If its concentration is too low, sodium sulfide can convert to sodium bisulfite, making the mercury sulfide insoluble.

How does the reaction with aluminum foil in the polysulfide solution work?

-When aluminum foil is added to the polysulfide solution containing mercury sulfide, it reacts to reduce the mercury in the complex back to metallic mercury. The sodium sulfide is regenerated and produced in this reaction, along with sodium aluminate and water.

What steps are taken to purify the extracted mercury metal?

-The extracted mercury metal is purified through two washings: first with potassium permanganate to oxidize and separate metal impurities, and then with nitric acid to make any remaining metal impurities water-soluble and remove them.

How is the final yield of mercury determined after the purification process?

-The final yield of mercury is determined by the weight or volume of pure mercury obtained after the purification process. It is compared to the theoretical yield based on the amount of mercury sulfide used in the process.

Outlines

🌋 Mercury Sulfide and its Extraction Methods

The first paragraph introduces mercury as a rare element that typically occurs in nature as mercury sulfide, known as cinnabar. It discusses the two forms of mercury sulfide: the common red alpha form, which was historically used as a pigment called vermilion, and the rarer black beta form. The paragraph also explains the two primary methods of extracting mercury from mercury sulfide: thermal decomposition, which involves heating in the presence of oxygen and subsequent condensation of the mercury vapor, and chemical reduction, which is safer but generates contaminated waste. The video creator opts for a chemical method involving a polysulfide solution for safety and accessibility reasons.

🔬 Chemical Reduction of Mercury Sulfide

The second paragraph details the chemical reduction process of mercury sulfide using a polysulfide solution. It describes the preparation of a strong sodium hydroxide solution and its reaction with sulfur to form sodium sulfide and polysulfides. The process involves adding mercury sulfide to the solution, which leads to the precipitation of sulfur and a color change in the solution. Aluminum is then introduced to react with the mercury sulfide, reducing it to metallic mercury. The reaction is carefully monitored to prevent any loss of mercury and to ensure the complete reduction of mercury sulfide. The paragraph also touches on the challenges of using aluminum powder and the importance of maintaining a high concentration of sodium hydroxide to prevent the formation of sodium bisulfite.

⚗️ Purification and Recovery of Mercury

The third paragraph describes the purification and recovery process of the metallic mercury obtained from the chemical reduction. It involves the addition of aluminum to the reaction mixture until no more mercury sulfide is present. The mixture is then diluted with water to help separate the mercury from other substances. The mercury, being dense, sinks to the bottom and is separated from the remaining solid impurities. The paragraph also discusses the washing of the mercury with potassium permanganate and nitric acid to remove any remaining metal impurities, resulting in clean and shiny mercury metal. The quality of the final product is noted to depend on the purity of the original mercury sulfide.

🏆 Final Results and Cleanup

The final paragraph concludes with the outcome of the mercury extraction and purification process. The yield of mercury is measured to be 26 grams, which is less than expected due to the presence of silica gel and celite in the waste material. The paragraph also discusses the proper storage of mercury as a souvenir and its potential use in chemical synthesis. The video creator mentions a giveaway for subscribers and followers, with details provided in the video description. Lastly, the cleanup of the waste generated during the process is mentioned to be covered in a separate video.

Mindmap

Keywords

💡Mercury

💡Mercury Sulfide

💡Cinnabar

💡Thermal Decomposition

💡Chemical Reduction

💡Polysulfide Solution

💡Vermilion

💡Sodium Hydroxide

💡Aluminum

💡Potassium Permanganate

💡Nitric Acid

Highlights

Mercury sulfide, also known as cinnabar, is the most common natural form of mercury.

Mercury sulfide exists in two major forms: the red alpha form and the rarer black beta form.

Red cinnabar was historically used as a pigment called vermilion in paints and cosmetics, but has been phased out due to toxicity.

The black form of mercury sulfide, meta-cinnabar, is produced chemically and can be converted to the red form by heating above 400 °C.

Mercury can be extracted from its sulfide through thermal or chemical methods, with the chemical method being safer but producing contaminated waste.

A novel chemical method for extracting mercury, developed by plant1999, uses a polysulfide solution instead of sodium sulfide for increased accessibility.

The process involves dissolving mercury sulfide in a sodium hydroxide solution and adding aluminum to reduce the mercury back to its metal form.

A large excess of sodium hydroxide is used to prevent the hydrolysis of sodium sulfide and to maintain the solubility of mercury sulfide.

The reaction with aluminum produces mercury metal, sodium aluminate, and water, while regenerating sodium sulfide.

The purity of the resulting mercury depends on the source of the mercury sulfide and may require further purification.

Potassium permanganate and nitric acid are used for washing the mercury to remove metal impurities and achieve a higher purity level.

The final yield of mercury from the process is 26 grams, indicating that most of the initial waste was non-mercury material like silica gel and celite.

The purified mercury can be used in chemical synthesis or as a souvenir, but must be stored properly to prevent spills or leaks.

The cleanup process of the chemical waste generated during the extraction is detailed in a separate video.

A giveaway is announced for NileRed beakers and keychains, with entry through subscription to the YouTube channel or following on Twitter.

The contest for the giveaway ends on Thursday, with the winner to be announced in the next video on Saturday.

Transcripts

5.0 / 5 (0 votes)

Thanks for rating: