Making Your Own Custom Coin

TLDRIn this episode of Switch & Lever, the host demonstrates how to create a personalized coin using a CNC mill. The process involves designing a 3D model of a head, either by using a 3D scanning software like Autodesk's 123D Catch or by converting a photo into a depth map. The model is then modified to fit the coin design. The host uses a Roland MDX-40A mill to mill a brass stock, emphasizing the importance of secure work holding and slow milling for metal. After milling, the coin is given an aged look with a blowtorch and spray paint, followed by polishing. The video concludes with the creation of a custom oak box for the coin, complete with a magnetic closure, showcasing the final product in a polished and professional manner.

Takeaways

- 🪙 The video outlines the process of creating a custom coin using a CNC mill from a brass stock.

- 🎥 Two methods for creating a 3D head model on a coin are discussed: using 123D Catch software for a 3D scan or converting a photo into a depth map for manual editing.

- 🤳 The 123D Catch method requires taking 50-100 photos for a full head model or fewer for a profile.

- 🖼️ For the photo-based method, hand painting is needed to create a depth map, which is then used to displace geometry in 3D software.

- 🔧 The Roland MDX-40A mill is used, which is not designed for milling metal, hence special attention is given to work holding and milling parameters.

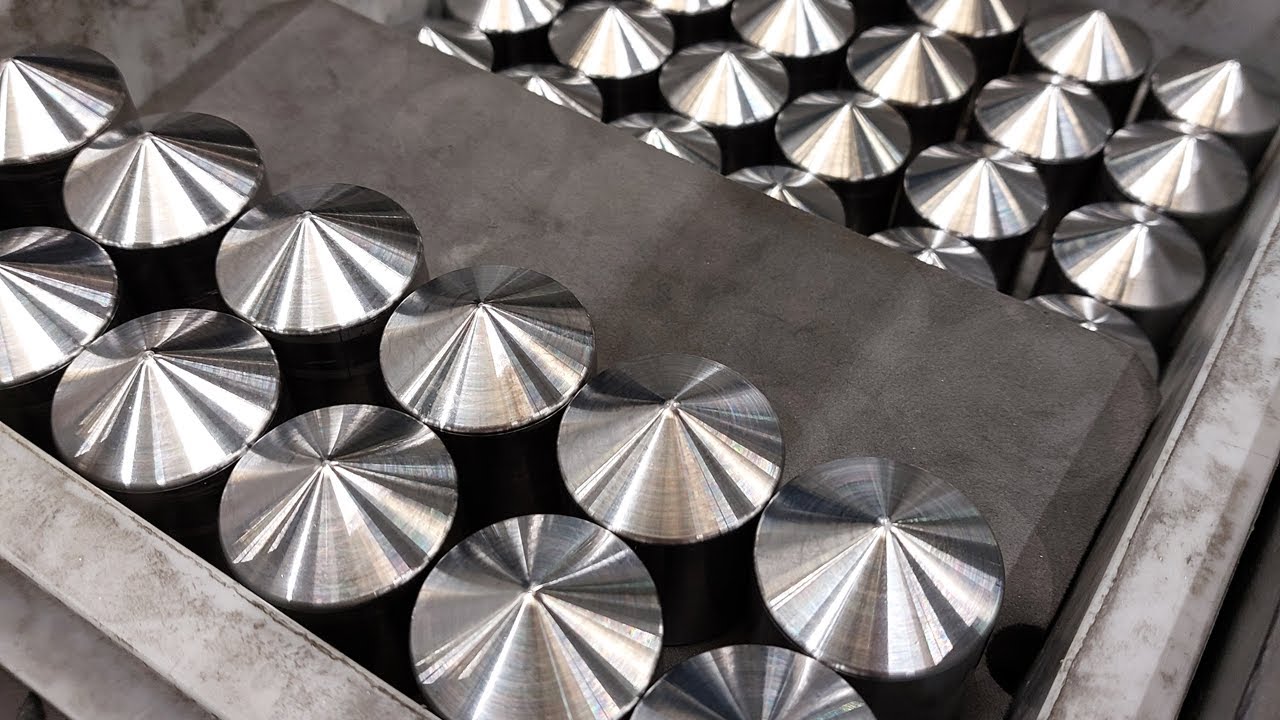

- 🔩 A new aluminum bed with holes was made for the mill to securely hold the workpiece during metal milling.

- 📏 The coin design includes marking the centerpoint for precise alignment when milling both the front and back sides.

- 🛠️ Milling is done slowly to avoid vibration, using an engraving cutter for detail and durability.

- 🌐 The brass coin is patinated using a blowtorch and matte black spray paint, followed by polishing with a compound like Autosol.

- 💡 Linseed oil is applied to darken and harden the patina over time.

- 🗃️ A custom oak box with a book-matched design and magnetic closure is created for the coin, showcasing the CNC mill's capabilities beyond coin making.

Q & A

What is the main topic of the video?

-The main topic of the video is the process of creating a coin using a CNC mill, specifically from a piece of brass stock.

How long have coins been around?

-Coins have been around for virtually forever, with various shapes and materials used throughout history.

What are the two methods for creating a realistic 3D head on a coin without modeling from scratch?

-The two methods are: 1) Using a 3D model of your head obtained through software like Autodesk's 123D Catch, and 2) Converting a photo into a depth map and then using photo editing and 3D software to create the coin's design.

What type of software is suggested for creating a 3D model from a series of photos?

-Autodesk's 123D Catch is suggested for creating a 3D model from a series of photos.

What type of CNC mill is used in the video?

-A Roland MDX-40A mill is used in the video, which is typically not designed for milling metal and requires special attention.

How was the workpiece secured for milling the coin?

-The workpiece was secured by drilling four holes in it to match the holes in a newly made aluminum plate bed, ensuring a stable hold during milling.

What was the milling process like for the coin?

-The milling process involved slow milling, taking fractions of a millimeter at a time, with a roughing pass followed by a finishing pass to remove material and create detail.

How was the patina created on the coin?

-The patina was created by heating the brass with a blowtorch to remove shine and oxidize the surface, followed by applying matte black spray paint and polishing with a metal compound like Autosol.

What was the final step to enhance the coin's appearance?

-The final step was to treat the coin with linseed oil to darken the paint and harden it over time, giving the coin a more aged and realistic look.

What additional project was undertaken to complement the coin?

-A custom box was made using a CNC mill from a piece of oak, with recesses for three coins and features like hinges and magnets to keep the box closed.

What tip is given for filming detailed work in a dusty or grimy environment?

-To protect the camera lens from dust and grime while filming detailed work, it is suggested to cover the camera with saran wrap, ensuring it is stretched tightly to avoid distortions.

Outlines

🛠️ Introduction to Coin Making with CNC Mill

This paragraph introduces the video's theme of creating a coin using a CNC mill. It discusses the history and variety of coins, and encourages viewers to make their own. The video focuses on making a 3D coin with a realistic head design, either by using an existing 3D model or by converting a photo into a depth map. The paragraph also mentions the use of a Roland MDX-40A mill for this project and the importance of proper work holding when milling metal.

🎨 Patination and Finishing Techniques for the Coin

This paragraph details the process of patinating and finishing the coin to give it an aged and realistic appearance. It covers the use of a blowtorch to heat the brass, creating an oxidized and dull surface, followed by applying matte black spray paint and wiping it off to leave paint in the recesses. The paragraph also explains the use of a metal polishing compound to polish the high spots and create a layered patina. Additionally, it suggests using linseed oil to darken the paint and harden it over time. The video concludes with the creation of a custom box for the coin, highlighting the ease of doing so with access to a CNC mill.

Mindmap

Keywords

💡CNC mill

💡3D modeling

💡Depth map

💡Patination

💡Linseed oil

💡Custom box

💡Blowtorch

💡Metal polishing compound

💡123D Catch

💡Engraving cutter

💡Milling machine

Highlights

Creating a coin using a CNC mill is explored in this video.

Coins have been made in various shapes and materials throughout history, including metal, wood, plastic, and even chocolate.

The video introduces two methods for creating a realistic 3D head on a coin without modeling from scratch.

Autodesk's 123D Catch software can transform a series of photos into a 3D model of your head.

For a detailed 3D model of your head, you need to take between 50 and 100 photos from every angle.

The 3D model is then bisected and compressed to fit the coin's profile.

A photo of the person can be converted into a depth map for coin design if a 3D model is not available.

Depth maps require hand painting in photo editing software to achieve the desired look.

The video uses a Roland MDX-40A mill, which is not designed for milling metal and requires special attention.

A new aluminum bed with holes was made for secure workpiece holding during metal milling.

The coin is milled slowly in fractions of a millimeter to prevent vibration and ensure precision.

An engraving cutter with a 90-degree angle is used for both sturdiness and fine detail creation.

The coin milling process takes 2-3 hours per side, starting with a roughing pass followed by a finishing pass.

The coin's patina is enhanced using a blowtorch, matte black spray paint, and a metal polishing compound.

Linseed oil is applied to darken and harden the patina over time.

A custom oak box with recesses for three coins and neodymium magnets for closure is also created.

The video provides tips for camera protection in dusty environments using saran wrap.

The final product is a detailed coin with an aged patina and a matching oak box, showcasing the capabilities of CNC milling.

Transcripts

Browse More Related Video

5.0 / 5 (0 votes)

Thanks for rating: