Royal Mint (1956)

TLDRThe Royal Mint in London strikes about 10 million coins weekly, supplying not only the UK but also half the world. The coin production involves meticulous processes, from alloy preparation to weight verification, ensuring the coins' exact specifications. The minting process includes annealing the blanks, stamping, milling, and a final visual inspection before the coins are bagged for dispatch. The Royal Mint, a state-owned industry with a 2,000-year history, is renowned for its efficient production methods and the hardness of its coins, now made without silver to conserve the metal for industry.

Takeaways

- 🏰 The Royal Mint in London strikes about 10 million coins every week for use in Britain and other countries.

- 💰 The coins produced are made from various metals including cpro nickel, real silver, brass, and bronze.

- 🔍 Each morning and day end, the weight of the metal and coins is carefully noted to ensure accuracy.

- 📏 The strips of metal for coins are rolled to an exact thickness, accurate to a 2,000th of an inch.

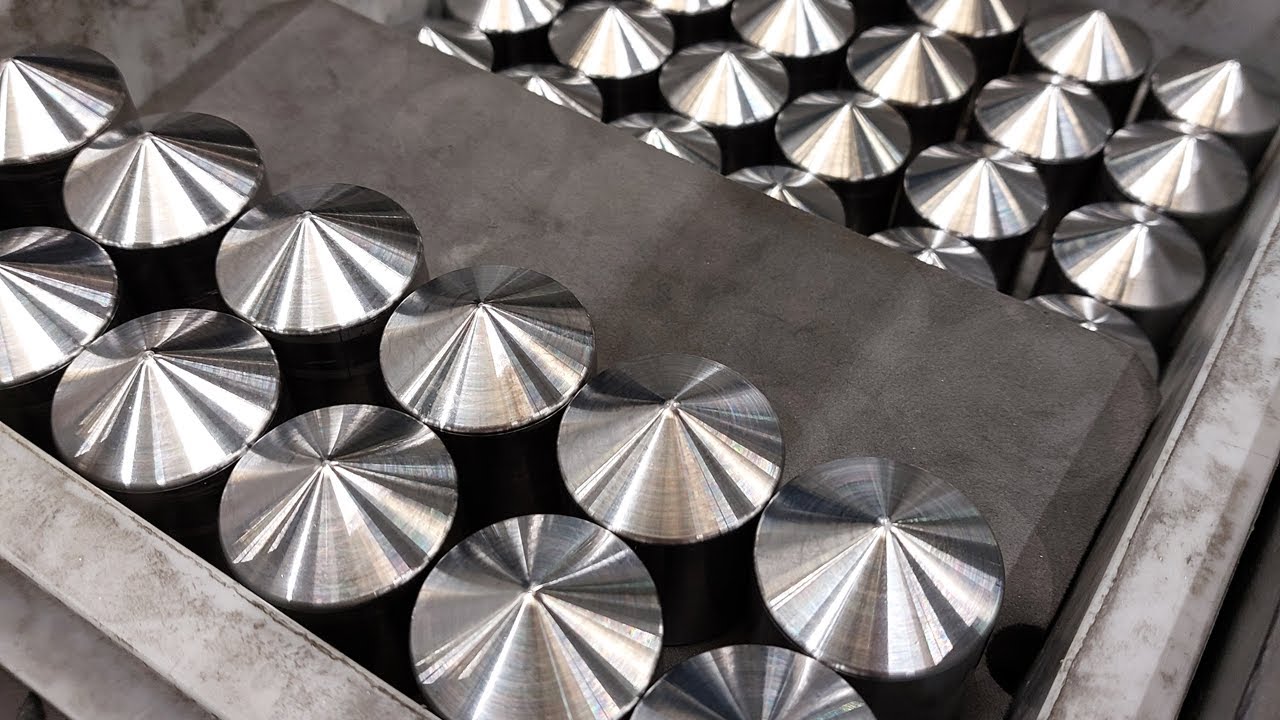

- 🎯 The coin blanks are punched out by a blanking machine to ensure their weight is correct to specification.

- 🔨 Coin blanks are annealed or slightly softened in a furnace before die stamping to prepare them for the stamping process.

- 🧪 After stamping, the softened blanks are cleaned by acid in pickling drums before being dried by hot air.

- 🏅 The Royal Mint is renowned for the hardness of its coins, which is a significant selling point.

- 🏢 As one of the oldest state-owned industries with a history dating back 2,000 years, the Royal Mint continually seeks to improve production efficiency.

- 👀 Quality control is strict, with trained checkers visually inspecting coins and rejects being melted down the next day.

- 💼 The accepted coins are counted into bags for dispatch, ensuring the circulation of legal tender.

Q & A

How many coins are struck at the Royal Mint every week?

-About 10 million coins are struck at the Royal Mint every week.

Where is the Royal Mint located?

-The Royal Mint is located on London's Tar Hill.

What types of coins are produced at the Royal Mint?

-The Royal Mint produces coins not only for use in Britain but also for half the world, including so-called silver coins made of cpro nickel and real silver for some foreign coins, as well as brass and bronze coins.

How is the alloy for the coins produced?

-The alloy for the coins is melted down and cast into bars, which are then rolled out into long strips of the exact thickness required for the coins.

What is the significance of the weight of the coins?

-The weight of the coins is carefully noted, as all governments insist that the weight of their coins should be exact to a fraction of a grain. This ensures the coins meet the required specifications.

How are the coin blanks prepared for die stamping?

-The coin blanks are annealed or slightly softened in a furnace in preparation for the die stamping process.

What is the role of the pickling drums in the coin production process?

-The pickling drums are used to clean the softened coin blanks by acid treatment before they are dried by hot air.

How are the coins checked for quality?

-A final visual check is made by trained checkers who watch the coins coming around a double moving belt, and rejects are sent for melting down.

How are the coins counted and packaged for dispatch?

-The coins are sent onto a machine that automatically counts them into bags for dispatch.

What was the historical silver content of the coins before the war?

-Before the war, the coins would have contained 50% silver.

What is the current silver content of the coins produced by the Royal Mint?

-Today, the coins produced by the Royal Mint contain no silver at all, with the metal being saved for industrial use.

How does the Royal Mint contribute to the economy and industry?

-The Royal Mint contributes to the economy by producing legal tender coins and also supports industry by saving silver for industrial applications.

Outlines

🏭 The Royal Mint's Coin Production

This paragraph discusses the operations at the Royal Mint in London, highlighting its significant role in producing coins not only for the UK but also for half the world. It mentions the production of 10 million coins per week, the materials used such as nickel, silver, brass, and bronze, and the meticulous process of ensuring the coins' weight and specifications are met. The importance of the coin's hardness and the Royal Mint's focus on efficiency and security in its production methods are also emphasized. The paragraph concludes by noting the historical significance of the mint, dating back 2,000 years, and the modernization of its processes.

Mindmap

Keywords

💡Royal Mint

💡Coin production

💡Weight and specification

💡Security measures

💡Annealing

💡Die stamping

💡Milling

💡Pickling

💡Legal tender

💡State-owned industry

💡Efficiency in production

Highlights

The Royal Mint in London strikes about 10 million coins every week.

Coins are minted not only for Britain but also for half the world.

The Royal Mint uses cpro nickel for silver coins and real silver for some foreign coins.

Brass and bronze are also utilized in the coin-making process at the Royal Mint.

Each morning, the weight of old and new metal is carefully noted for accuracy.

The weight of coins made at the end of the day must match the initial metal weight.

The Royal Mint is known for the hardness of its coins, which is a significant selling point.

Coin blanks are annealed or slightly softened in a furnace before die stamping.

The history of the Royal Mint dates back 2,000 years to Julius Caesar's time.

The Mint is constantly innovating to increase production efficiency.

Coins are stamped on both sides and milled on the edges with high precision.

Silver coins are made by squeezing the blank between two dies and a grooved collar.

The coin production process operates at 90 to 120 blows per minute.

A final visual check is conducted by trained checkers to ensure coin quality.

Rejected coins are melted down the next day, while合格的 are bagged for dispatch.

Pre-war coins contained 50% silver, but today they contain no silver, preserving it for industry.

Despite changes in composition, coins remain legal tender and valuable currency.

Transcripts

Browse More Related Video

5.0 / 5 (0 votes)

Thanks for rating: