Behind the scenes at the Royal Mint: Logistics

TLDRThe Royal Mint, renowned for producing coins for over 80 countries, showcases its intricate coin-making process in this insightful video. From the creation of blanks to the final packaging, the Mint emphasizes its commitment to sustainability, using biodegradable materials and reusable wooden boxes. The video highlights the diversity of packaging requirements, the use of robots for efficient bag packing, and the meticulous quality control measures, including a final weigh-check. It also reveals the existence of an emergency store for UK coins, ready to meet fluctuating demands throughout the year, particularly during peak times like Christmas.

Takeaways

- 🏅 The Royal Mint has a history of manufacturing coins for over 80 different countries, each with unique requirements.

- 🚀 Customers can order blanks from the Royal Mint to strike their own coins, in addition to purchasing ready-made coins.

- 📦 The packaging process for coins involves counting and packing machines that use biodegradable materials like polythene and wooden boxes for environmental sustainability.

- 🤖 Robots are utilized in the packing process to efficiently place bags of coins into boxes for the next stage of preparation.

- 🌍 Coins and blanks are distributed worldwide, with the Royal Mint catering to the specific needs and packaging preferences of each country.

- 📈 The Royal Mint uses a planning and production system to manage the timing and method of packing orders based on customer requirements.

- 🔄 Packaging materials have evolved to be more sustainable, with wooden boxes and biodegradable liners replacing less eco-friendly alternatives.

- 📊 A final weighing process ensures that each package meets the specified requirements before being sealed, labeled, and dispatched.

- 🚚 The Royal Mint maintains an emergency store of UK coins ready for distribution to banks, especially during periods of high demand like Christmas.

- 💡 Innovative thinking and a diverse workforce are crucial for solving logistical challenges in coin manufacturing and distribution.

- 🎥 For more insights, the Royal Mint's museum offers educational videos at royalmidmuseum.org.uk.

Q & A

What is the main focus of the transcript?

-The main focus of the transcript is the process of coin and medal manufacturing at the Royal Mint, including the challenges of meeting the specific requirements of over 80 different countries and the logistics involved in distributing the coins.

How does the Royal Mint accommodate the different needs of various countries?

-The Royal Mint accommodates the different needs of various countries by producing coins according to each country's specific requirements, including different shapes, sizes, and packaging methods.

What are 'blanks' in the context of coin production?

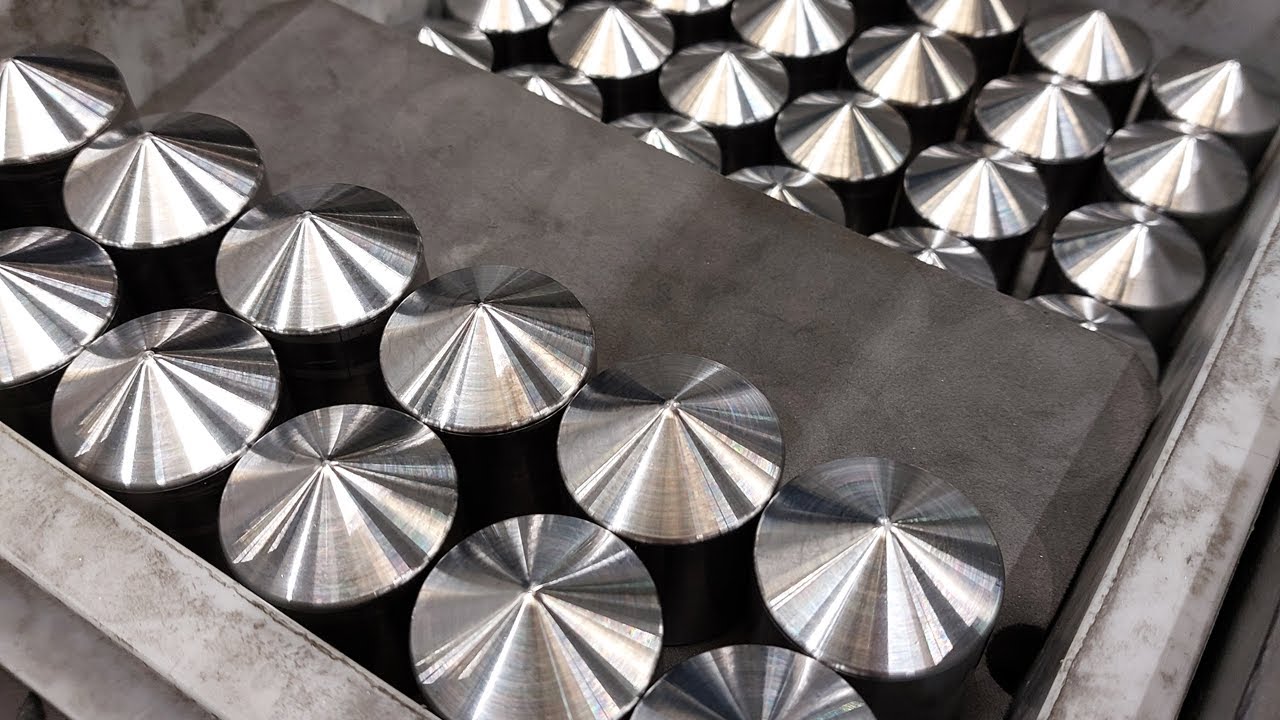

-In the context of coin production, 'blanks' refer to the coin-shaped metal pieces that have not yet been struck with a design. Customers can purchase these blanks from the Royal Mint to strike their own coins.

What type of packaging does the Royal Mint use for environmental reasons?

-The Royal Mint uses biodegradable polythene and wooden boxes for packaging to minimize environmental impact. They have also moved from cardboard boxes to reusable cages for UK coins and use biodegradable inner liners.

How does the Royal Mint ensure accurate counting and packing of coins?

-The Royal Mint uses counting and packing machines equipped with sensors that send an electrical signal each time a coin passes over them. This process ensures accurate counting and helps in packing coins into boxes, bags, or other specified containers.

What is the role of robots in the coin packing process?

-Robots play a role in the coin packing process by automatically placing bags of coins into boxes, readying them for the next stage of manual packing or dispatch.

What is the purpose of the scales area in the coin production process?

-The scales area is used for a final check to ensure that the packages meet the required specifications, such as the correct number of bags or coins, before they are sealed, labeled, and dispatched to the customer.

What is the significance of the long store of boxes mentioned in the transcript?

-The long store of boxes contains UK one-pound coins and other related items. It serves as an emergency store that can be called upon by banks as needed, especially during times of increased demand, such as during the holiday season.

How does the Royal Mint handle the logistics of coin production and distribution?

-The Royal Mint handles the logistics of coin production and distribution through a combination of innovative thinking, planning systems, and production systems that dictate when and how coins need to be packed and dispatched to customers worldwide.

What is the role of the Royal Mint in the global economy?

-The Royal Mint plays a significant role in the global economy by producing coins for more than 80 different countries, facilitating international trade and financial transactions through the supply of currency.

Outlines

🏭 Royal Mint's Coin Production and Packaging

This paragraph provides an in-depth look into the Royal Mint's process of manufacturing coins and medals for over 80 different countries, each with unique requirements. It highlights the use of blanks for customers who prefer to strike their own coins and the environmentally friendly packaging methods, such as biodegradable polythene and wooden boxes. The paragraph also discusses the counting and packing machines, the variety of packaging options available to meet customer needs, and the logistics involved in dispatching the coins to various countries. The emphasis on sustainability is noted, with the shift from cardboard boxes to reusable wooden crates and biodegradable inner liners.

📦 Quality Control and Dispatch at the Royal Mint

The second paragraph focuses on the quality control and dispatch processes at the Royal Mint. It describes the scales area where packages are weighed to ensure they meet specifications, including the correct number of bags. The process continues with labeling and scanning before the packages are sent to the dispatch area for delivery to customers. The paragraph also mentions the Royal Mint's emergency store of UK one pencils, which is called upon by banks as needed, especially during peak times like Christmas. The importance of logistics and innovative thinking in solving logistical problems is emphasized, with a call to visit the Royal Mint's website for more information.

Mindmap

Keywords

💡Royal Mint

💡coin making process

💡blanks

💡counting and packing machine

💡biodegradable packaging

💡customer requirements

💡sustainability

💡logistics

💡innovation

💡emergency store

💡production system

Highlights

The Royal Mint has made coins for more than 80 different countries, each with slightly different requirements.

Customers can order blanks from the Royal Mint to strike their own coins.

The coin making process includes a counting and packing machine that uses environmentally friendly materials like biodegradable polythene.

The Royal Mint's packaging is designed to be sustainable, with the use of wooden boxes and biodegradable materials.

Coins are counted using a sensor that sends an electrical signal each time a coin passes over it, allowing for high-speed counting.

The Royal Mint can produce up to 150,000 coins per box.

Coins are sent to various countries worldwide, including Morocco, with each country receiving a slightly different product.

The Royal Mint offers a variety of packaging options, such as wood cartons, metal drums, and different sizes of bags, to meet customer needs.

Robots are used to automate the packing of coin bags into boxes, improving efficiency.

The Royal Mint uses a planning system to manage the packing and dispatch of orders.

Packages are weighed as a final check to ensure they meet specifications before being dispatched.

The Royal Mint maintains an emergency store of UK coins for times when banks require them, such as during the holiday season.

Innovative thinking is crucial for solving logistical problems in coin making, which is why the Royal Mint employs a diverse range of people.

The Royal Mint's commitment to sustainability includes using materials that can be reused or biodegrade, reducing environmental impact.

The Royal Mint's operations are a blend of manual and automated processes, ensuring both precision and efficiency.

The Royal Mint's ability to adapt to the specific needs of different countries showcases its flexibility and global reach.

The Royal Mint's focus on sustainability extends to the use of reusable cages for UK coins, replacing cardboard boxes.

The Royal Mint's dispatch process is streamlined, with a 24/7 operation to ensure timely delivery to customers.

Transcripts

5.0 / 5 (0 votes)

Thanks for rating: