What's the difference between Proof, Brilliant Uncirculated and Bullion coins?

TLDRThe Royal Mint's experts, including Chief Engraver Gordon Summers, Master Tools Maker Tony Milsom, Senior Die Polisher David Woodward, and Setter Paul Barrington, share insights into the meticulous processes behind creating commemorative coins. They detail the three finishes—Bullion, Brilliant Uncirculated, and Proof—with a focus on craftsmanship and quality. The Proof coin, representing the pinnacle of quality, involves extensive hand-finishing and striking to achieve a detailed, high-relief design, resulting in a limited production of 50 coins per hour.

Takeaways

- 🏅 Gordon Summers, Chief Engraver at The Royal Mint, has 20 years of experience.

- 🏆 The Royal Mint produces three types of commemorative coins: Bullion, Brilliant Uncirculated, and Proof.

- 📈 These coin production processes have been refined over a thousand years or more.

- 🛠️ The Mint's focus is on craftsmanship, skill, and knowledge, regardless of the coin's finish.

- 🔍 The level of care in the production process is significant and varies based on the coin's final finish.

- 🏦 Bullion coins prioritize efficient production, with a focus on quantity.

- 🌟 Brilliant Uncirculated coins are of higher quality than circulation coins, with additional polishing.

- 🎯 Proof coins represent the highest quality finish, with meticulous attention to detail in striking.

- 🛠️ Tony Milsom, Master Tools Maker, ensures the dies are sharp for accuracy in coin design.

- 💎 David Woodward, Senior Die Polisher, uses diamond paste and various woods for a perfect mirror finish.

- 🔨 Paul Barrington, a Setter, highlights the manual process for Proof coins, struck up to six times for fine detail.

Q & A

How long has Gordon Summers been working at The Royal Mint?

-Gordon Summers has been working at The Royal Mint for about 20 years.

What are the three types of finishes produced by The Royal Mint for commemorative coins?

-The Royal Mint produces three types of finishes for commemorative coins: Bullion, Brilliant Uncirculated, and Proof.

What is the primary focus of The Royal Mint in producing coins?

-The primary focus of The Royal Mint is to produce the highest quality coin, regardless of the finish, by putting a great deal of craftsmanship, skill, and knowledge into every design and every coin.

How does the production process differ for Bullion, Brilliant Uncirculated, and Proof coins?

-The production process for Bullion coins focuses on efficient production in large quantities. Brilliant Uncirculated coins receive an extra finish and more polishing compared to circulation coins. Proof coins involve the highest quality finish, with more time spent on tooling and striking to ensure the highest quality.

What is Tony Milsom's role at The Royal Mint?

-Tony Milsom is a Master Tools Maker at The Royal Mint, responsible for ensuring the dies are sharp and accurate to make the finish on the coin as close to the original design as possible.

How does the process for the Proof finish differ in terms of tooling and striking?

-For the Proof finish, more time is spent on the tools, often working in deeper relief to allow extra material for additional polishing. The striking process is more meticulous to achieve the highest quality coin.

What is David Woodward's role and how does he contribute to the quality of the final coins?

-David Woodward is the Senior Die Polisher at The Royal Mint. He polishes the dies used to strike the coins to ensure the highest quality finish on the final coins, using diamond paste and different woods to achieve a perfect mirror finish.

How many times are Proof coins struck during the production process?

-Proof coins are struck up to six times using less pressure to preserve the fine detail of the artwork.

What is the Setter's role in the production of Proof coins?

-The Setter, like Paul Barrington, hand-places each blank into the press for Proof coins, cleans the dies with air before each strike, and ensures that only around 50 Proof coins are produced per hour with maximum detail and quality.

What recommendations are given for someone interested in buying gold coins based on their purpose?

-For the value of the gold alone, Bullion coins are recommended. For higher quality but more accessible coins, Brilliant Uncirculated is suggested. However, for the highest quality and craftsmanship, Proof coins are the best choice.

How does the final check of the coins ensure their quality?

-Every coin is checked when they come off the press to ensure perfection in line-up, diameter, and overall quality.

Outlines

🏅 Introduction to The Royal Mint and Coin Finishes

Gordon Summers, Chief Engraver at The Royal Mint, introduces the three types of finishes for commemorative coins produced at the mint: Bullion, Brilliant Uncirculated, and Proof. He emphasizes the thousand-year-old refining process and the focus on craftsmanship, skill, and knowledge that goes into every coin design and production. The meticulous care taken in the coin-making process is highlighted, with a particular note on the different levels of quality and finish for each type of coin.

🛠️ The Art of Master Tool Making

Tony Milsom, a Master Tools Maker, discusses the role of tool makers in ensuring the accuracy and sharpness of the dies used for coin production. He explains that for the Proof finish, more time is spent on the tools to achieve a closer representation of the original design. The process of sharpening and inspecting the tools to maintain quality standards is detailed, along with the importance of the Master Tools in achieving the highest quality coin finish.

💎 The抛光 Process of Die Polishing

David Woodward, Senior Die Polisher, outlines the polishing process for the dies used to strike coins. He describes the use of diamond paste and various woods to achieve a mirror finish, with an additional stage for the Proof finish involving tape protection and a frosting effect created with sand and glass bead blasters. The time-consuming nature of polishing each Proof die is emphasized, highlighting the production capacity and the meticulous attention to detail required for each coin.

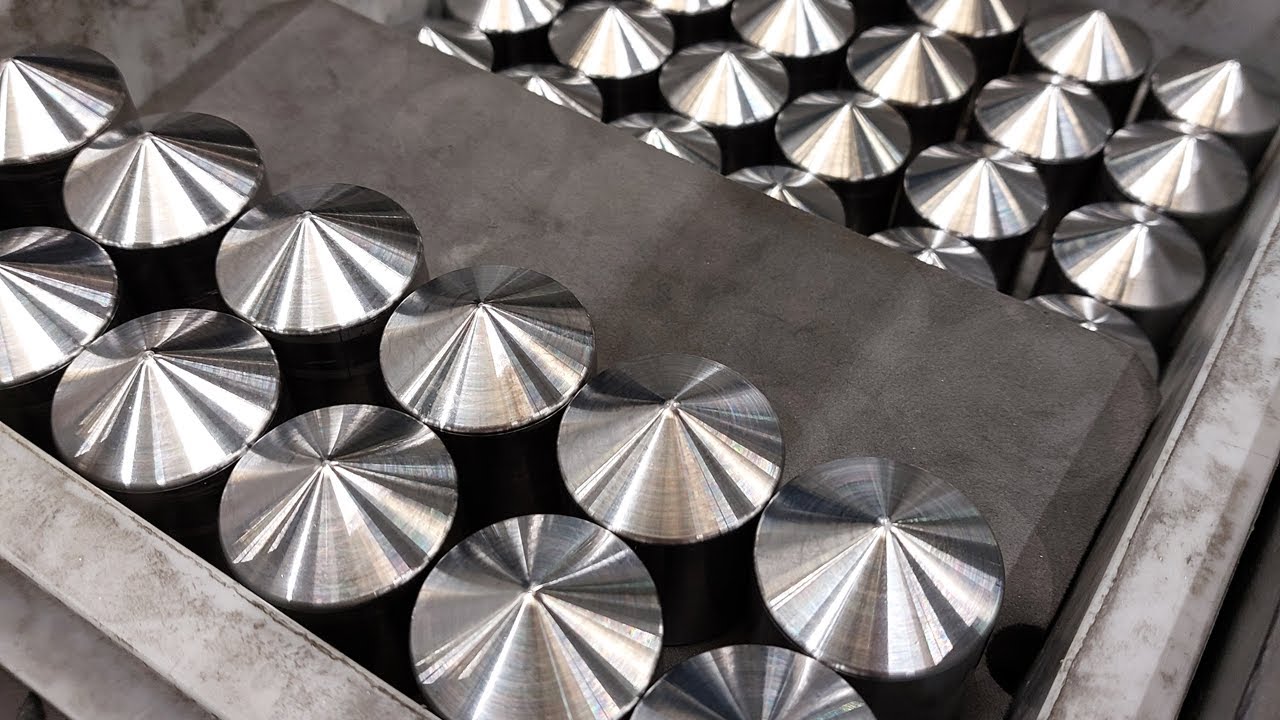

🏗️ Coin Striking and Production Techniques

Paul Barrington, a Setter at The Royal Mint, explains the coin striking process for Bullion, Brilliant Uncirculated, and Proof coins. He details the machine-feeding process for Bullion and Brilliant Uncirculated coins, the striking frequency, and the production rates. For Proof coins, the hand-placed process, air cleaning of dies, and the lower production rate due to the extra care and detail preservation are discussed. The ability of Proof coins to showcase more detail and finer craftsmanship is highlighted, as well as the quality checks performed on each coin post-production.

💰 Recommendations for Coin Buyers

The script concludes with advice for potential coin buyers. It suggests Bullion coins for those interested in the gold value, Brilliant Uncirculated for a higher quality coin accessible to more people, and Proof coins for those seeking the utmost quality and craftsmanship. The emphasis is on the unique qualities and finishes of each coin type, guiding buyers to make an informed decision based on their preferences and intentions.

Mindmap

Keywords

💡Chief Engraver

💡Commemorative Coins

💡Bullion

💡Brilliant Uncirculated

💡Proof Coin

💡Master Tools Maker

💡Die Polishing

💡Setter

💡Coin Striking

💡Quality Control

💡Investment and Collectibility

Highlights

Gordon Summers is the Chief Engraver at The Royal Mint with 20 years of experience.

The Royal Mint produces three types of finishes for commemorative coins: Bullion, Brilliant Uncirculated, and Proof.

Coin production processes at The Royal Mint have been refined over a thousand years.

The focus at The Royal Mint is to produce the highest quality coin regardless of its finish.

Craftsmanship, skill, and knowledge are integral to every coin design and production at The Royal Mint.

Bullion coins are produced for efficiency, with a focus on quantity.

Brilliant Uncirculated coins have a higher quality finish than circulation coins, with additional polishing.

Proof coins represent the highest quality finish, with extensive time spent on tooling and striking.

Tony Milsom is a Master Tools Maker with 18 years of experience at The Royal Mint.

Dies are sharpened and inspected to ensure the finish on the coin closely matches the original design.

For Proof finish coins, tools are often worked in deeper relief and require more polishing.

David Woodward is the Senior Die Polisher with 38 years at The Royal Mint.

Dies for Bullion coins are finished by a polishing machine, while those for Brilliant Uncirculated and Proof are hand-finished.

Six grades of diamond paste and different woods are used to achieve a perfect mirror finish on the dies.

The Proof finish includes an additional frosting effect created by sand and glass bead blasting.

Each Proof die can take several hours to finish and produces 300-400 coins before needing re-polishing.

Paul Barrington is a Setter at The Royal Mint, with 11 years of experience.

Bullion coins are machine-fed and struck once, with a production rate of 250 coins per hour.

Brilliant Uncirculated coins are struck twice, checked regularly, and produced at a rate of 100 coins per hour.

Proof coins are hand-placed, struck up to six times, and produced at a rate of 50 coins per hour.

Proof coins offer more detail, clearer relief, and a smoother surface, showcasing the original design's best.

Each coin is inspected for perfection upon production, including line-up, diameter, and overall quality.

Bullion coins are recommended for those interested in the gold value, while Brilliant Uncirculated and Proof coins offer higher quality and craftsmanship.

Transcripts

Browse More Related Video

Behind the scenes at the Royal Mint: Striking

Behind the scenes at the Royal Mint: Master tools

Revealing The Hidden Treasures Of The Royal Mint Museum

Royal Mint (1956)

Behind the scenes at the Royal Mint: Design

Valuable Hunt~The Elizabeth Global Coins values-World Top 3 Ultimate Pence Worth COINS 2023

5.0 / 5 (0 votes)

Thanks for rating: