Behind the scenes at the Royal Mint: Striking

TLDRThe Royal Mint's coin minting process is a fascinating blend of engineering and precision. With the ability to produce up to 750 coins per minute, the facility strikes and assembles millions of coins weekly. The intricate process involves high-speed machinery, blank loading, striking, and packaging for distribution. Bi-metallic coins like the pound and two-pound coins require a specialized assembly, combining inner and outer rings. Quality control is ensured through testing machines, with each coin subjected to significant pressure to ensure its integrity. The Royal Mint's enduring legacy and efficiency are a testament to the remarkable engineering behind the simple coin in your pocket.

Takeaways

- 🏭 The Royal Mint is renowned for its expertise in minting coins and medals, with a fascinating process that can produce up to 750 coins per minute.

- 🔨 The coin minting process involves loading blanks into hoppers, which are then struck at high speed, with the capability of producing 45,000 coins an hour.

- 🏅 The circulating coin department is responsible for striking, packing, and distributing coins like 10 pence and 20 pence pieces to customers.

- 🏓 The factory floor can produce a staggering 120 million coins in a week, showcasing the efficiency of the Royal Mint's operations.

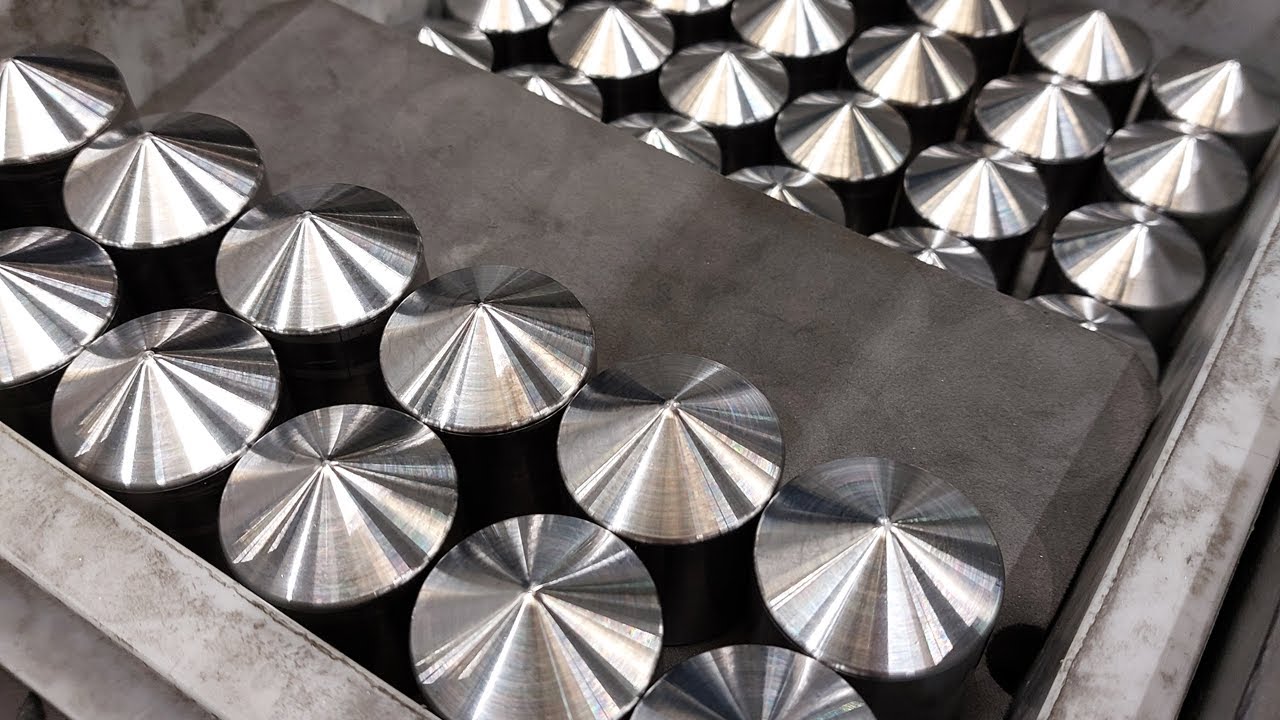

- 💰 Bi-metal coins, such as the pound and two-pound coins, are made from two different colored materials and are assembled using a specialized process.

- 🔄 The inner and outer rings of bi-metal coins are combined using a bridge and tube system, which feeds the inners into the rings and assembles them before striking.

- 🛠️ The striking process involves a significant amount of pressure, with 80 tons used to strike the coins and create the groove that locks the inner and outer rings together.

- 🧪 Quality control is crucial, with a push-up machine used to test the coins after minting, applying a minimum of 1.2 kilonewtons of force to ensure the coin's integrity.

- 📈 Despite the Royal Mint's long history spanning over a thousand years, the coin minting process is continuously evolving to maintain efficiency and adapt to new technologies.

- 🌐 The Royal Mint's operations highlight the complexity and engineering prowess required to produce millions of coins that end up in everyday use.

Q & A

What is the Royal Mint known for?

-The Royal Mint is known for being one of the best in the world at minting coins, medals, and more.

Where does the video take place?

-The video takes place within the Royal Mint's circulating coin department.

What types of coins are produced in the department shown in the video?

-The department produces circulation coins like 10 pence and 20 pence coins.

What is the maximum number of coins that can be minted per minute?

-The maximum number of coins that can be minted per minute is 750.

How many coins are produced on a weekly basis?

-The Royal Mint produces about 120 million coins per week.

What is the process for making bi-metal coins like the pound coin?

-Bi-metal coins are made by assembling an inner ring with a different colored material, which is then pressed into the outer ring in the striking area.

What is the purpose of the push-up machine?

-The push-up machine is used to test the coins after they have been made, specifically to ensure the inner ring is properly locked into the outer ring.

How much pressure is used in the striking process?

-The striking process uses a minimum of 1.2 kilonewtons of pressure, which is equivalent to about 1.2 tons.

How does the striking process affect the coin's groove?

-When the press strikes the coin, it exerts pressure that causes the groove to expand and lock into the outer ring.

What can we learn from the video about the Royal Mint's history?

-We learn that the Royal Mint has been around for more than a thousand years and has continuously adapted its processes to become highly efficient.

Where can one find more information about the Royal Mint?

-More information about the Royal Mint can be found on their website at barmouthmuseum.org.uk.

Outlines

🏭硬币制造过程揭秘

本段落介绍了硬币制造的过程,特别是皇家铸币厂如何高效地制作硬币。皇家铸币厂以其卓越的铸币技术而闻名,能够以每分钟750枚的速度生产流通硬币,如10便士和20便士硬币。硬币的制造涉及将金属坯料装载到料斗中,通过机器的高速运转,硬币被快速制造并打包发送给客户。此外,还介绍了双金属硬币(如1英镑和2英镑硬币)的制造过程,包括如何将两种不同颜色和材质的金属结合在一起。

🤔硬币制造的复杂性与效率

这段视频脚本强调了尽管硬币在我们日常生活中看似简单,其制造过程却涉及复杂的工程技术。皇家铸币厂不仅历史悠久,而且其生产过程极为高效,能够在短时间内制造大量硬币。此外,视频还展示了硬币制造过程中的质量控制环节,例如使用压力机测试硬币的紧密度和结构完整性。整个段落传达了对铸币工艺的赞赏,以及对皇家铸币厂持续创新和改进其生产技术的钦佩。

Mindmap

Keywords

💡Royal Mint

💡Minting

💡Coin Production

💡Bi-Metal Coins

💡Engineering

💡Strike

💡Hoppers

💡Dies

💡Striking Area

💡Assembly Line

💡Efficiency

Highlights

The Royal Mint's coin minting process is fascinating and highly efficient.

The Royal Mint is one of the best in the world at minting coins.

The circulating coin Department is responsible for striking and packing coins like 10 pence and 20 pence.

Coins are produced at a high speed of up to 750 per minute.

The machines can produce 45,000 coins per hour.

Blanks are loaded into hoppers and struck coins are taken to an exit.

Each day, the factory floor produces about 120 million coins.

Bi-metal coins like the pound and two pound coins are made from two different colored materials.

A ring system is used to assemble the inner and outer parts of bi-metal coins.

The push-up machine tests the coins by applying a minimum of 1.2 kilonewtons of pressure.

The Royal Mint has been around for over a thousand years and continues to evolve its processes.

Despite the simplicity of a coin, its production involves complex engineering and numerous arms of engineering.

The environment within the Royal Mint is highly efficient, capable of making 12 coins in one second.

The process of making coins is not often thought about, but it is surprisingly brilliant.

For more information about the Royal Mint, one can visit the Barmouth Museum's website.

Every UK coin in circulation has originated from the Royal Mint.

The coin minting process is intricate and involves a significant amount of engineering.

Transcripts

Browse More Related Video

5.0 / 5 (0 votes)

Thanks for rating: