An Introductory Torque Wrench Problem

TLDRIn the video script, Mr. P and his students explore the concept of torque through a practical physics problem involving a lag bolt. They start by calculating the force needed to tighten the bolt with a wrench, given an initial force and angle. The discussion then shifts to finding the new force required when the angle changes, leading to a correction about the actual angle involved. The sine function's properties are highlighted, showing how supplementary angles result in the same torque value. The problem's complexity increases with the addition of a pipe that extends the wrench, altering the distance from the bolt and necessitating a recalculation of the force. The video concludes with a real-world application, noting that mechanics use 'cheater pipes' to increase torque but must be cautious to avoid wrench angular acceleration. The engaging conversation not only solves the problem but also emphasizes the importance of understanding torque and its practical implications.

Takeaways

- 🔩 The lag bolt is a type of fastener with a screw on one end and a hexagonal nut on the other.

- 🔧 To tighten a lag bolt, a force of 29N is applied at a 90-degree angle using a wrench positioned 0.18 meters from the bolt's center.

- 📐 When the angle between the wrench and the force is changed to 50 degrees, the magnitude of the force required to maintain the same torque changes.

- 🤔 The actual angle between the wrench and the force when it's 50 degrees is 130 degrees, not 50, due to the vector directions.

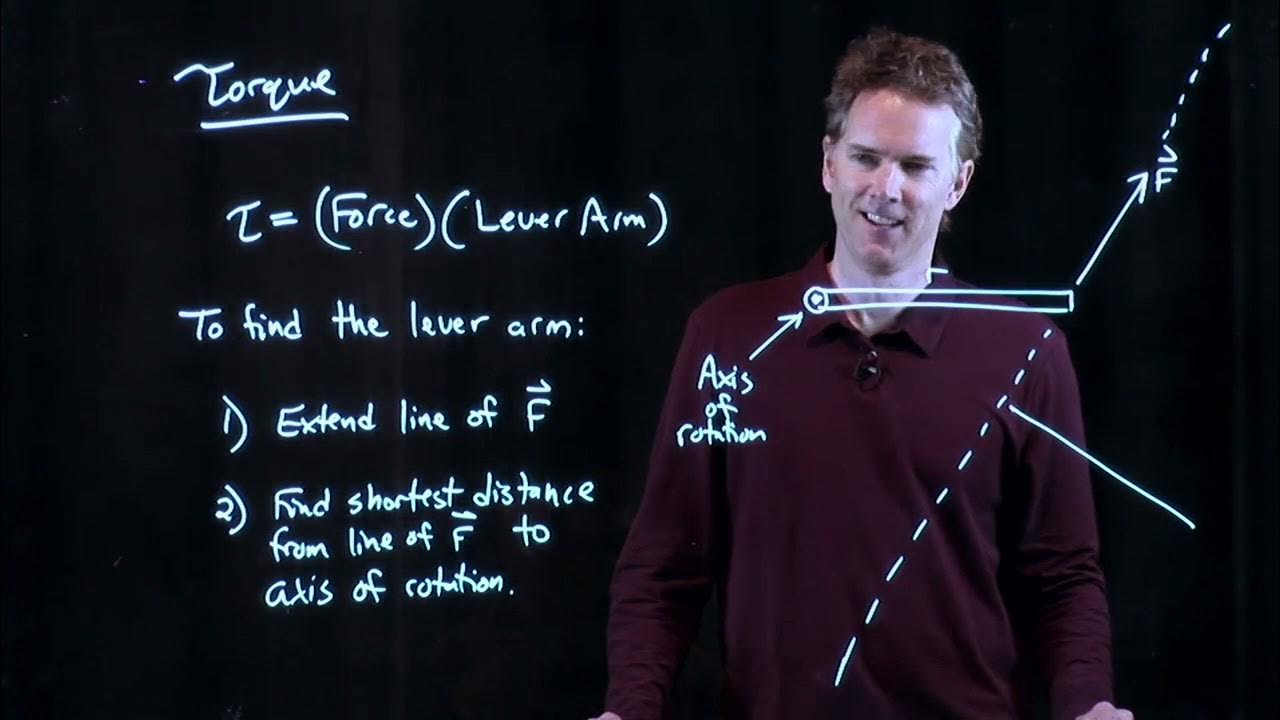

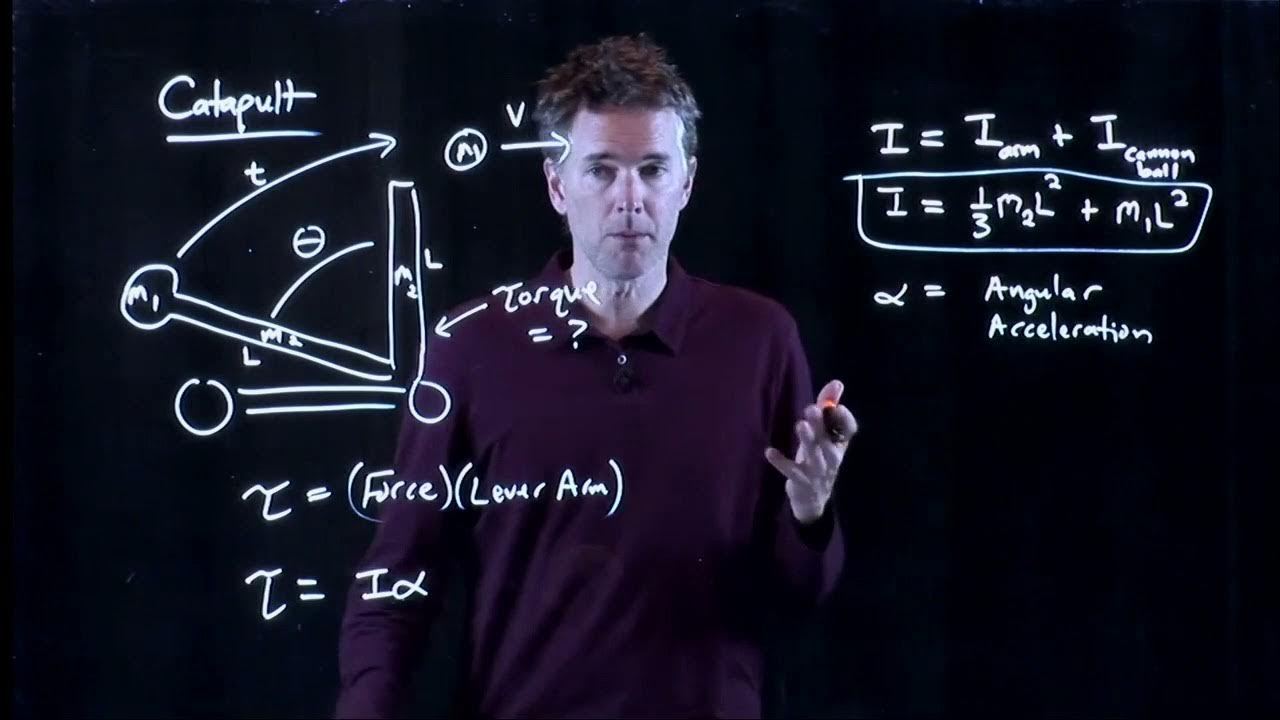

- 🧮 Torque is calculated as the product of the distance from the axis of rotation (r), the force applied (F), and the sine of the angle (theta).

- 🟢 The sine of supplementary angles (like 50 and 130 degrees) are equal, which means the torque calculation remains the same despite the angle change.

- 🔄 Both torques (torque 1 and torque 2) are equal, and torque 2 can be rearranged to solve for the new force (force 2).

- 🔢 By using the correct angle and the given torque value, the force required at the new angle is calculated to be approximately 38N.

- 🚿 Real-world applications may not be perfect due to factors like friction, which can affect the actual force applied.

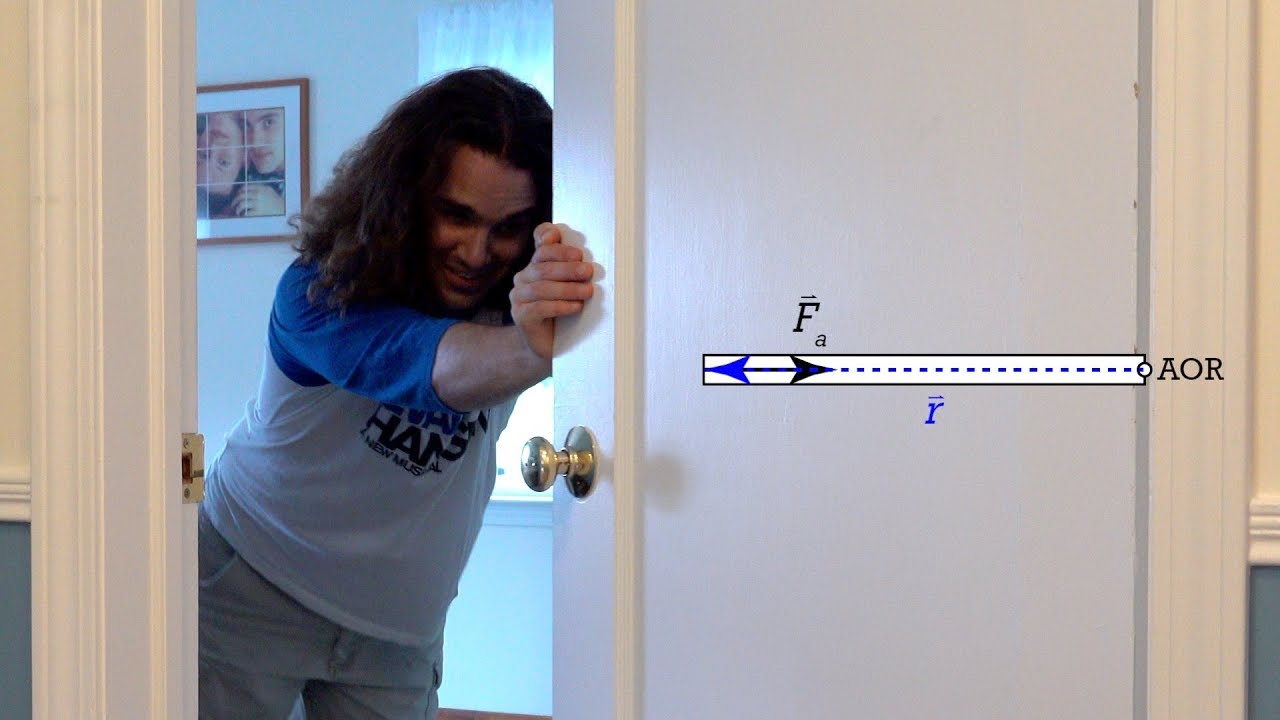

- 📏 Adding a pipe to the wrench increases the distance from the lag bolt (r3), which can be used to calculate the minimum force needed to achieve the same torque.

- 🔧 For the minimum force, the angle (theta 3) should be 90 degrees, where the sine function is maximized, resulting in a force of approximately 4.8N.

- ⚙️ Mechanics often use a 'cheater pipe' to extend the length of their wrenches, increasing the torque they can apply but with caution to avoid angular acceleration of the wrench itself.

Q & A

What is a lag bolt and how does it differ from a regular bolt?

-A lag bolt, also known as a lag screw, has a screw thread on one end and a hexagonal nut on the other. It is designed to be tightened into wooden beams or posts, providing a strong fastening mechanism.

What is the significance of the angle between the wrench and the force when tightening a lag bolt?

-The angle is crucial because it affects the torque applied to the bolt. Torque is the product of the force applied, the distance from the axis of rotation (r), and the sine of the angle (theta). A 90-degree angle provides the maximum torque since sine of 90 degrees is 1.

Why is it important to consider the vector nature of torque when solving the problem?

-Although the problem is asking for the magnitude of the force, it's essential to remember that torque is a vector quantity. This means it has both magnitude and direction. Understanding this helps to correctly apply the torque equation and solve for the unknown force.

What is the relationship between supplementary angles and their sine values?

-Supplementary angles, which add up to 180 degrees, have sine values that are identical. This is because the sine function is symmetrical about 90 degrees, so sine(90 + x) equals sine(90 - x).

How does changing the angle between the wrench and the force affect the necessary force to achieve the same torque?

-If the angle decreases from 90 degrees, a larger force is required to maintain the same torque, because the sine of the angle (which is in the torque equation) decreases, making the overall torque smaller.

What is the role of a 'cheater pipe' in mechanics?

-A 'cheater pipe' is a metal pipe used by mechanics to extend the length of their wrenches. This increases the lever arm, allowing for greater torque to be applied, which can be useful for loosening or tightening nuts and bolts that are hard to reach or require significant force.

Why might a mechanic need to be careful when using a 'cheater pipe'?

-Using a 'cheater pipe' can lead to angular acceleration of the wrench rather than the bolt if too much torque is applied. This can result in the wrench bending or breaking, which is why caution is advised.

What is the formula for calculating torque?

-The formula for calculating torque (τ) is τ = r * F * sin(θ), where r is the distance from the axis of rotation to where the force is applied, F is the force applied, and θ is the angle between the force and the direction of r.

How does the friction between the wood and the screw affect the actual force needed to tighten the bolt?

-Friction between the wood and the screw can cause the actual force needed to tighten the bolt to be higher or lower than the calculated force. Inconsistencies in friction can lead to variations from the theoretical values.

What is the minimum magnitude force necessary to cause the same torque as before when a pipe is fitted to the wrench?

-When the distance between the lag bolt and where the force is applied is increased to 1.08 meters, the minimum magnitude force necessary to cause the same torque as before is approximately 4.8 newtons, assuming the angle is 90 degrees for maximum torque.

Why is it assumed that the angle should be 90 degrees when calculating the minimum force required with the pipe fitted to the wrench?

-It is assumed to be 90 degrees because the sine of 90 degrees is 1, which maximizes the torque for a given force and distance. When looking for the minimum force required to achieve a certain torque, maximizing the sine component by using a 90-degree angle is the most efficient approach.

Outlines

🔩 Understanding Lag Bolts and Torque Calculations

The first paragraph introduces the concept of a lag bolt, which is a type of screw with a hexagonal nut on one end. The discussion revolves around calculating the torque required to tighten a lag bolt. Initially, a force of 29 newtons is applied at a 90-degree angle to a wrench 0.18 meters from the bolt's center. The problem then explores the effect of changing the angle to 50 degrees, leading to a correction that the actual angle is 130 degrees due to the direction vectors involved. The torque is calculated using the formula \\(τ = r × F × sin(θ)\\), where \\(τ\\) is the torque, \\(r\\) is the distance from the axis of rotation, \\(F\\) is the force applied, and \\(θ\\) is the angle between the force and the direction of \\(r\\). The correct angle usage and the sine function's property of supplementary angles are highlighted. The final calculation results in a force of approximately 38 newtons needed at the new angle.

🛠️ The Impact of Lever Arm Length on Torque

The second paragraph delves into the mechanics of using a wrench with an added pipe, or 'cheater pipe,' to increase the torque applied to a lag bolt. It explains that by increasing the distance from the force application point to the bolt, the torque can be increased, as demonstrated by the formula \\(τ = r × F × sin(θ)\\). The scenario assumes an angle of 90 degrees for maximum torque efficiency, resulting in a minimum force requirement of approximately 4.8 newtons. Practical considerations are also discussed, such as the potential for angular acceleration of the wrench itself and the need for caution to avoid damage. The paragraph concludes with a real-world application of torque principles, noting that mechanics often use a cheater pipe to gain additional leverage.

Mindmap

Keywords

💡Lag Bolt

💡Torque

💡Force

💡Angle

💡Wrench

💡Hexagonal Nut

💡Significant Figures

💡Supplementary Angles

💡Cheater Pipe

💡Friction

💡Angular Acceleration

Highlights

A lag bolt is defined as having a screw on one end and a hexagonal nut on the other.

The initial force applied to tighten the lag bolt is 29N at a 90-degree angle from the wrench.

The distance from the center of the lag bolt to the force is specified as 0.18 meters.

When the angle is changed to 50 degrees, the magnitude of the force required to maintain the same torque is questioned.

The torque equation involves the force, the distance (r vector), and the sine of the angle between the force and the r vector.

The torque is a vector, and vector symbols are used in the equation despite focusing on magnitude.

The correct angle for the force vector when the wrench is at 50 degrees is actually 130 degrees, not 50 degrees, due to vector direction.

The sine of supplementary angles (e.g., 130 and 50 degrees) are identical, which simplifies the torque calculation.

The calculated force necessary at the new angle is approximately 38N, rounded to two significant digits.

Friction between the wood and the screw can cause discrepancies in the actual force applied.

A pipe can be added to the wrench to increase the distance and thus the torque, known as a 'cheater pipe'.

The minimum force required with a 1.08-meter distance using a cheater pipe is calculated to be 4.8 newtons.

Mechanics use cheater pipes to extend wrenches for increased torque, but caution is advised to prevent wrench angular acceleration.

The practical demonstration shows that the calculated force is close to the actual force applied with a cheater pipe.

The transcript includes a cautionary note about the potential for wrench bending due to excessive torque with a cheater pipe.

The discussion emphasizes the importance of understanding torque, force, and the r vector in practical applications.

The educational dialogue concludes with an affirmation of the value of learning and the enjoyment of the process.

Transcripts

Browse More Related Video

5.0 / 5 (0 votes)

Thanks for rating: