Fractional Distillation | Organic Chemistry | Chemistry | FuseSchool

TLDRThis video script explains the process of fractional distillation, which separates crude oil into useful fractions based on their boiling points. Crude oil, a mixture of hydrocarbons with varying chain lengths, is heated and passed through a fractionating column with a heat gradient. Smaller molecules with lower boiling points rise and condense higher in the column, while larger molecules with higher boiling points condense lower. The resulting fractions, such as petrol, naphtha, kerosene, diesel oil, and bitumen, have diverse applications in fuels and manufacturing.

Takeaways

- 🌟 Crude oil is unprocessed oil extracted directly from the ground, either on land or under the sea, and is a valuable resource for various organic compounds.

- 🔍 Crude oil is a mixture of hydrocarbons with different chain lengths, which affects the intermolecular forces and boiling points of its components.

- 🔥 Fractional distillation is the process used to separate the different hydrocarbon fractions in crude oil based on their boiling points.

- 🌡 Small molecules with weaker intermolecular forces have lower boiling points and require less energy to evaporate, while larger molecules with stronger forces have higher boiling points.

- 🌡️ The fractionating column has a heat gradient, with the bottom being hotter and the top cooler, which helps in the separation of hydrocarbons.

- 📊 Hydrocarbons with similar boiling points are collected in the same tray, forming fractions that are useful for different applications.

- 🛢️ Fractional distillation produces various fractions such as petrol, naphtha, kerosene, diesel oil, and bitumen, each with specific uses.

- 🚗 Petrol is a fraction used as a fuel for cars, demonstrating the practical applications of the separated hydrocarbons.

- ✈️ Kerosene is another fraction, used as aircraft fuel, highlighting the importance of these fractions in transportation.

- 🏭 Naphtha is used in the manufacture of chemicals and as a fuel, showing the versatility of the hydrocarbon fractions.

- 🛤️ Bitumen, a large chain hydrocarbon mixture, is used for road construction and roofing, illustrating the wide range of applications for the fractions.

- 📚 Understanding the relationship between chain length, intermolecular forces, and boiling points is crucial for the effective separation of crude oil into useful fractions.

Q & A

What is crude oil and why is it valuable?

-Crude oil is unprocessed oil taken directly from the ground or under the sea. It is valuable because it provides a multitude of organic compounds used as fuels and in the production of various chemicals and plastics.

Why is fractional distillation necessary for crude oil?

-Fractional distillation is necessary to separate the different hydrocarbon fractions in crude oil, which have varying viscosities and consistencies, making them useful for different applications.

How does the chain length of hydrocarbons in crude oil affect their boiling points?

-The chain length of hydrocarbons affects their boiling points because longer molecules have greater intermolecular forces, requiring more energy and higher temperatures to evaporate, thus having higher boiling points.

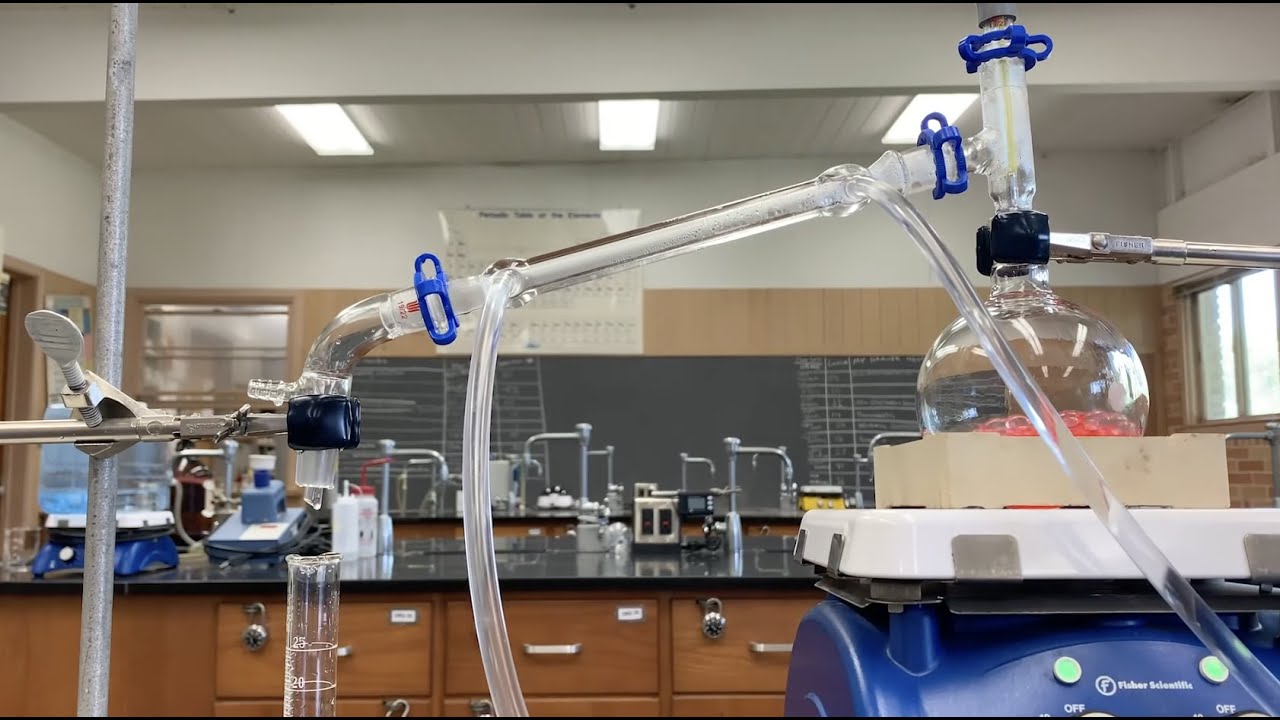

How does the fractionating column create a heat gradient?

-The fractionating column has a heat gradient where it is very hot at the bottom and gets cooler as it goes up to the top, which helps in separating hydrocarbons based on their boiling points.

What is the role of bubble caps in the fractionating column?

-Bubble caps in the fractionating column slow down the rate of rising vapor, allowing the vapor to cool down, condense, and be collected in trays at different heights within the column.

How are hydrocarbons with similar boiling points collected in the fractionating process?

-Hydrocarbons with similar boiling points are collected in the same tray of the fractionating column because they condense at similar temperatures, forming fractions.

What is the purpose of each fraction obtained from fractional distillation?

-Each fraction obtained has specific uses; for example, petrol is used as a fuel for cars, naphtha in chemical manufacturing and as a fuel, kerosene as aircraft fuel, diesel oil for vehicles, and bitumen for road construction and roofing.

What happens to the long chain molecules with high boiling points in the fractionating column?

-Long chain molecules with high boiling points begin to condense back into a liquid even at the high temperatures at the bottom of the column and are collected at the bottom.

Where are small chain molecules collected in the fractionating column?

-Small chain molecules, which have lower boiling points, are collected at the top of the column where the temperature is cooler.

How does the fractional distillation process contribute to the usefulness of crude oil?

-Fractional distillation separates crude oil into useful fractions with similar boiling points, allowing for the efficient utilization of each fraction in various industries and applications.

What is the significance of understanding the relationship between chain length and boiling point in fractional distillation?

-Understanding the relationship between chain length and boiling point is crucial for effectively separating crude oil into its component fractions, each with specific applications and properties.

Outlines

🛢️ Fractional Distillation of Crude Oil

This paragraph introduces the process of fractional distillation, which is used to separate crude oil into useful fractions. Crude oil, extracted directly from the ground or sea, is a mixture of hydrocarbons with varying chain lengths. The paragraph explains how intermolecular forces and boiling points are related to the chain length of hydrocarbons. It then describes the fractional distillation process, where crude oil is heated and pumped into a column with a heat gradient. Different fractions of hydrocarbons are collected at various heights in the column, based on their boiling points. The paragraph concludes with examples of the various fractions obtained from crude oil and their uses, such as petrol, naphtha, kerosene, diesel oil, and bitumen.

Mindmap

Keywords

💡Fractional Distillation

💡Crude Oil

💡Hydrocarbons

💡Boiling Point

💡Intermolecular Forces

💡Fractionating Column

💡Petrol

💡Naphtha

💡Kerosene

💡Diesel Oil

💡Buitmen

Highlights

Crude oil is unprocessed oil taken directly from the ground, both on land and under the sea.

Crude oil is a valuable resource providing numerous organic compounds used as fuels and in chemical and plastic manufacturing.

Raw crude oil has a viscous, dark, tar-like consistency with different hydrocarbon fractions needing separation for utility.

Fractional distillation is the process used to separate the different hydrocarbon fractions in crude oil.

Crude oil is a mixture of hydrocarbons with varying chain lengths, affecting their intermolecular forces and boiling points.

Shorter hydrocarbon molecules have weaker intermolecular forces and lower boiling points, requiring less energy to evaporate.

Longer hydrocarbon molecules have stronger intermolecular forces and higher boiling points, needing more energy to become gaseous.

The fractionating column has a heat gradient, with the bottom being hotter and the top cooler, aiding in the separation of hydrocarbons.

Heating crude oil outside the column turns it into vapor before it's pumped in, initiating the distillation process.

Long chain molecules with high boiling points start to condense back into liquid at the bottom of the column.

Smaller molecules with low boiling points condense higher in the column where it's cooler.

Hydrocarbons with similar boiling points are collected in the same tray, forming fractions.

Fractions have various important uses, such as petrol for cars, naphtha in chemical manufacturing, and kerosene as aircraft fuel.

Diesel oil is a fraction used as fuel for vehicles like cars, vans, and lorries.

Buitmen, a large chain hydrocarbon fraction, is used for road construction and roofing.

Fractional distillation separates crude oil into useful fractions with similar boiling points, based on the chain length of hydrocarbons.

Small chain molecules are collected at the top of the column due to their lower boiling points, while large chain molecules are collected lower down due to higher boiling points.

Transcripts

Browse More Related Video

Crude Oil Fractions & Their Uses | Organic Chemistry | Chemistry | FuseSchool

GCSE Chemistry - Fractional Distillation and Simple Distillation #50

Simple and fractional distillations | Chemical processes | MCAT | Khan Academy

Boiling Point of Organic Compounds

Simple Distillation

2.3 Vapor Pressure, IMFs, and Boiling Point

5.0 / 5 (0 votes)

Thanks for rating: