SPC - The Lean Six Sigma Tool You Must Know (Statistical Process Control)

TLDRThe video script introduces Statistical Process Control (SPC), a foundational tool for Six Sigma developed by Walter Shewhart in the 1920s. It emphasizes SPC's importance and common misuse, which leads to inefficiencies. SPC is likened to monitoring the health of a process, using the analogy of a six-sided dice to explain how SPC identifies process anomalies. The script advises against using specifications in SPC, illustrating the potential for increased defects when operators adjust processes based on customer specifications rather than monitoring for natural process variations.

Takeaways

- 💼 Statistical Process Control (SPC) is a powerful tool for improving efficiency and profitability in a company.

- 📈 SPC originated from the work of Walter Shewhart at Bell Telephone Companies in the 1920s and is the foundation of Six Sigma.

- 📊 SPC is often misused and underused, leading to inefficiencies and waste in many companies.

- 🔍 The purpose of SPC is to 'listen to the voice of the process' and check its health, rather than the health of individual parts.

- 🎲 Processes can be thought of as random number generators influenced by various variables, making them difficult to predict.

- 📉 Understanding the average (signal), range (noise), and distribution of a process is crucial for SPC.

- 🚫 SPC should not be used with specifications to drive the process, as it can lead to increased defects and inefficiency.

- 🔑 When a process produces an unexpected result, such as rolling a seven with a six-sided dice, it should trigger an investigation.

- 📋 Monitoring the spread, shape, and average of a process allows for the detection of unusual behavior that requires correction.

- 🛠️ Operators should not be influenced by customer specifications when using SPC to avoid altering the process unnecessarily.

- 📈 By correctly implementing SPC, companies can reduce defect rates and improve overall process performance.

Q & A

What is Statistical Process Control (SPC)?

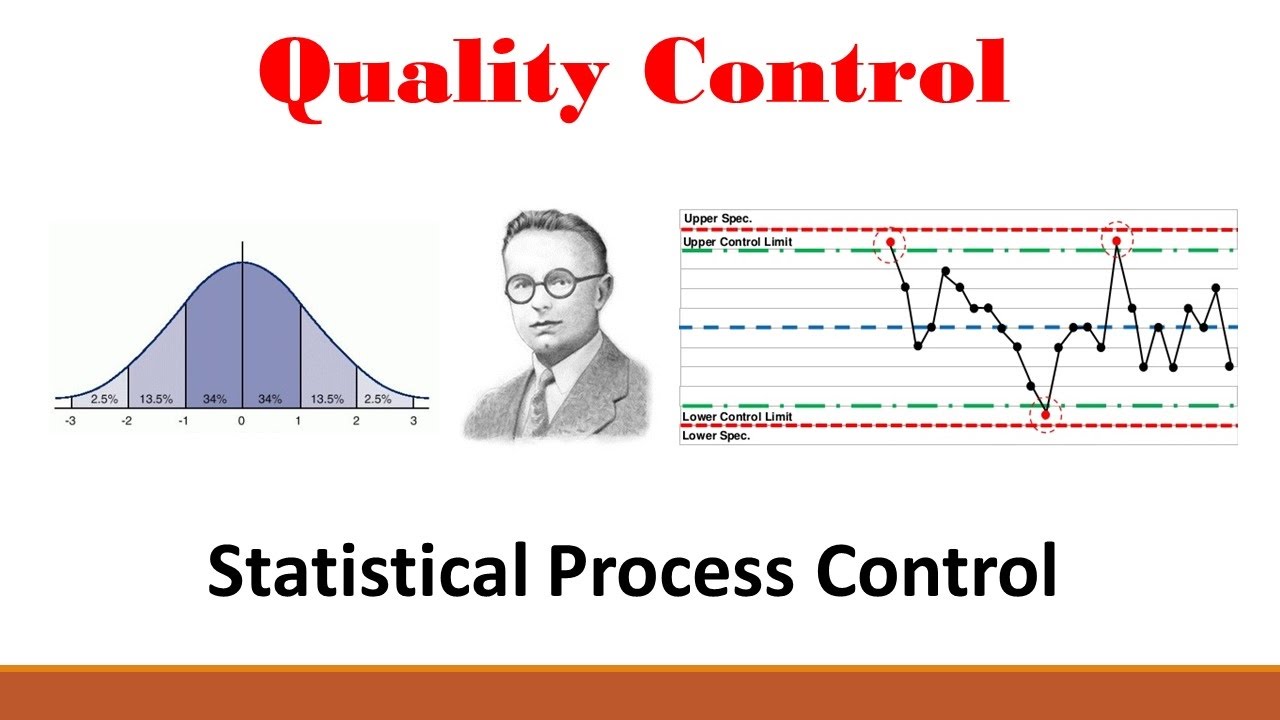

-Statistical Process Control (SPC) is a method of quality control that employs statistical methods to monitor and control a process. It was developed by Walter Shewhart at the Bell Telephone Companies in the 1920s and is considered the genesis of Six Sigma.

Why is SPC considered the most misused and underused tool in many companies?

-SPC is considered misused and underused because, in many cases, it is either not applied correctly or not utilized at all, leading to inefficiencies and waste. Companies often do not understand what SPC is, even when they use it.

What does the phrase 'listening to the voice of the process' mean in the context of SPC?

-The phrase 'listening to the voice of the process' refers to the ability of SPC to provide insights into the process's behavior and performance, allowing for better understanding and control.

How does SPC help in checking the health of a process?

-SPC helps in checking the health of a process by monitoring the spread, shape, and average of the process's output. It allows for the detection of unusual behavior that may indicate a problem that needs investigation and correction.

What is an example of a process being described in the script, and what are its characteristics?

-The example given is a six-sided dice, which is a random number generator. Its characteristics include an average (signal) of 3.5, a range (noise) between 1 and 6, and an equal distribution for each number.

What is the significance of the tolerances or specifications in the context of the dice example?

-The tolerances or specifications set the acceptable range for the product, in this case, between 0 and 8. If the dice roll results in a number outside this range, it is considered an unexpected outcome that warrants investigation.

Why should specifications not be used to run an SPC process?

-Specifications should not be used to run an SPC process because they can lead to overcorrection by operators, which can shift the process and potentially worsen its performance, as illustrated by the example of the dice rolling ones and sixes.

What is the recommended approach for using SPC in a company?

-The recommended approach is to monitor SPC without operators being aware of the specifications. This allows the process to be observed and corrected based on its inherent behavior without the risk of overcorrection.

How can a company determine if they are using SPC correctly?

-A company can determine if they are using SPC correctly by assessing whether they are monitoring the process's spread, shape, and average without overcorrecting based on specifications, and by investigating any unusual behavior in the process.

What is the importance of understanding the process's spread, shape, and average in SPC?

-Understanding the process's spread, shape, and average is crucial in SPC as it provides the basis for identifying when the process is behaving unusually. This allows for timely investigation and correction of any issues, ensuring process stability and quality.

Outlines

📈 Introduction to Statistical Process Control (SPC)

This paragraph introduces the concept of Statistical Process Control (SPC), highlighting its origin from the work of Walter Shewhart at Bell Telephone Companies in the 1920s. It emphasizes SPC as a foundational tool for Six Sigma and its common misuse, which can lead to inefficiencies and waste. The paragraph also introduces the idea of SPC as a method to listen to the 'voice of the process' and to check its health, rather than the health of individual parts. An analogy of a six-sided dice is used to explain the unpredictability of processes and the importance of understanding process variability, average, and distribution to identify when a process is not behaving as expected.

Mindmap

Keywords

💡Statistical Process Control (SPC)

💡Six Sigma

💡Control Chart

💡Voice of the Process

💡Process Health

💡Random Number Generator

💡Signal and Noise

💡Tolerances and Specifications

💡Defect Rate

💡Investigation

💡Efficiency and Waste

Highlights

Statistical Process Control (SPC) is a powerful tool for increasing a company's profits.

SPC originated from the work of Walter Shewhart in the 1920s at Bell Telephone Companies.

Shewhart developed the control chart in 1924, a fundamental aspect of SPC.

SPC is often misused and underused, leading to inefficiencies and waste.

Most companies are unaware of what SPC is, even when they implement it.

SPC is described as 'listening to the voice of the process' to understand its health.

Processes are likened to random number generators, defined by various variables.

Understanding a process's health involves knowing its average, range, and distribution.

An example using a six-sided dice illustrates the concept of process health and tolerances.

Deviations from expected outcomes, like rolling a seven, should trigger investigations.

SPC helps in identifying when a process starts to behave unusually, prompting corrective actions.

Specifications should not be used to run the SPC process to avoid worsening the process.

Operators should not be influenced by customer specifications to prevent process shifts.

Correct SPC implementation involves monitoring without adjusting to specifications.

Misuse of SPC can increase defect rates and harm process efficiency.

The video encourages viewers to reflect on their company's SPC practices.

A call to action is made for viewers to like, subscribe, and engage with the content.

Transcripts

Browse More Related Video

Quality (Part 1: Statistical Process Control)

Introduction to Statistical Process Control Charts (Lean Six Sigma)

Die rolling probability | Probability and combinatorics | Precalculus | Khan Academy

PROCESS CAPABILITY: Explaining Cp, Cpk, Pp, Ppk and HOW TO INTERPRET THOSE RESULTS

Does Mindfulness Meditation Work for ADHD

The 7 Quality Control (QC) Tools Explained with an Example!

5.0 / 5 (0 votes)

Thanks for rating: