What Happens if you MIX ALL The METALS Together?

TLDRIn this video, the host introduces a new periodic table display case filled with various metals and embarks on an experiment to create an alloy from these metals. The video is sponsored by Brilliant, an educational platform offering practical problem-solving tools across multiple disciplines. The host discusses the properties of metals, the concept of alloys, and the historical progression from the Bronze Age to the Iron Age. Several alloys are explored, including bronze, brass, stainless steel, and magnaloy, each with unique properties and applications. The host also attempts to create a custom alloy using 29 different metals, resulting in a surprisingly workable and hard material with ferromagnetic properties. The video concludes with a demonstration of the alloy's resistance to corrosion and an acknowledgment of the company Lucitre for providing metal cubes.

Takeaways

- 🔍 The video explores the melting and alloying of various metals to create new materials with unique properties.

- 🧪 The host begins by discussing the properties of metals and the concept of creating an alloy, inspired by the fictional material vibranium.

- 📚 The video is sponsored by Brilliant, an educational platform offering practical problem-solving tools in various disciplines.

- 🔨 Metals like iron and copper have specific uses due to their properties, but also have drawbacks, leading to the creation of alloys like bronze and brass.

- 🔥 The process of making bronze is demonstrated by melting copper and tin together in a graphite crucible, with borax used as a flux.

- 📊 Brass is created by melting copper and zinc, with borax again used to facilitate the process, though zinc's reactivity is noted.

- 🛠 The host discusses the properties of the resulting alloys, noting that bronze is harder but brass is more malleable and suitable for small components.

- 🧲 Stainless steel is introduced as an iron-based alloy, with chromium added for corrosion resistance, and magnesium fluoride used as a flux instead of borax.

- 🚜 Magnalloy, another iron-based alloy, contains manganese to increase durability, and is demonstrated to be non-magnetic despite its iron content.

- 🧲 The creation of an alloy called ulnico for magnets is mentioned, composed of iron, aluminum, nickel, and cobalt, with a special process required to make it magnetic.

- 🤔 The host attempts to create an 'incredible alloy' by melting 29 different metals, including precious and refractory metals, resulting in a hard, corrosion-resistant material with ferromagnetic properties.

- ⚙️ The final alloy, while not as extraordinary as vibranium, demonstrates that with the right proportions, various metals can be combined to produce materials with unusual properties.

Q & A

What is the main focus of the video?

-The video focuses on the process of creating various metal alloys, including bronze, brass, stainless steel, magnaloy, and an experimental alloy made from a mixture of 29 different metals.

What is the purpose of using borax and magnesium fluoride in the process?

-Borax and magnesium fluoride are used as fluxes to reduce the formation of slag during the melting process and to facilitate the mixing and bonding of the metals in the alloy.

Why did the creator decide to use iron as the base metal for the experimental alloy?

-Iron was chosen as the base metal for the experimental alloy because it serves as a common and versatile material that can dissolve other elements, acting as the main ingredient in the alloy.

What is the role of nickel and chromium in stainless steel?

-Nickel and chromium in stainless steel help to create a protective chromium oxide film that prevents the metal from oxidizing and makes it more resistant to corrosion.

Why did the creator choose not to include certain metals like uranium and mercury in the experimental alloy?

-The creator avoided using uranium and mercury due to their high toxicity, and also excluded alkaline metals like sodium or cesium because they would burn upon heating.

What property does the experimental alloy demonstrate when polished with an angle grinder?

-When polished with an angle grinder, the experimental alloy demonstrates resistance to corrosion as it almost doesn't spark, indicating its corrosion-resistant nature.

How does the addition of metals like cobalt and aluminum affect the alloy's properties?

-The addition of metals like cobalt and aluminum improves the alloy's casting properties, making it easier to fill the mold and resulting in a more even shape after cooling.

What is the significance of the company Lucitre in the video?

-Lucitre is a company that provided the creator with beautiful metal cubes for the video. They are acknowledged for their contribution, and a link to their site is promised to be included in the video description.

What happens when the creator tries to alloy all the metals together?

-When all the metals are alloyed together, the resulting material is quite hard, resistant to corrosion, and has ferromagnetic properties. It also surprises the creator with its unusual properties, although not as impressive as vibranium from Marvel comics.

Why did the creator decide to use an induction heater for the iron-based alloys?

-The creator chose to use an induction heater because the melting temperature of iron is over 1100 degrees Celsius, which exceeds the heat capacity of the old furnace. The induction heater can heat the graphite crucible to 1700 degrees Celsius, making it suitable for melting iron.

What is the difference between stainless steel and magnaloy in terms of their reaction to a magnet?

-Stainless steel, even though it's called 'stainless', is still attracted to a magnet due to its high iron content. Magnalloy, on the other hand, does not react to a magnet at all, indicating a difference in its composition and properties.

What are the key properties the creator is looking to achieve with the experimental alloy?

-The creator aims to achieve an alloy that is hard, rigid, resistant to corrosion, and possibly possesses ferromagnetic properties. The final alloy also needs to be easy to work with and exhibit unusual properties when combined in the right proportions.

Outlines

🔍 Exploring the Creation of Metal Alloys

The video begins with the host showcasing a new periodic table display case filled with various metals. The main focus is on the exploration of creating an alloy by melting different metals together. The host discusses the properties of metals like density, metallic shine, and conductivity, and how pure metals have limitations, leading to the creation of alloys with improved properties. The video is sponsored by Brilliant, an educational platform offering courses in various disciplines. The host demonstrates the process of making bronze and brass, two copper-based alloys, in a furnace. The process involves heating copper, adding tin for bronze and zinc for brass, and using borax as a flux to reduce slag formation. The host also mentions the upcoming creation of iron-based alloys, such as stainless steel, and the need for an induction heater to achieve the high temperatures required for melting iron.

🔧 Crafting Copper and Iron-Based Alloys

The host continues the experiment by discussing the creation of brass, an alloy of copper and zinc. Despite a mishap where zinc burns quickly at high temperatures, the host successfully creates brass and notes its suitability for small components. The video then transitions to the creation of stainless steel, an iron-based alloy that requires higher temperatures. The host explains the composition of stainless steel, which includes iron, nickel, and chromium, and the protective oxide film that chromium provides. An induction heater is introduced as a new tool for future experiments. The host also experiments with magnaloy, an iron-based alloy used for tank tracks, which includes manganese for durability. The properties of these alloys are demonstrated through various tests, including their reaction to magnets and resistance to oxidation.

🧲 Experimenting with Magnetic Alloys

The host explores the creation of magnetic alloys, starting with an ulnico alloy used in magnets. The composition includes iron, aluminum, nickel, and cobalt. The host details the process of melting these metals and casting them into a graphite mold. After cooling and polishing, the resulting alloy is tested for its magnetic properties. The host also attempts to create a unique alloy by combining 29 different metals, including precious and refractory metals, but excluding toxic elements like uranium and mercury. The resulting alloy is found to be hard, corrosion-resistant, and ferromagnetic. The host concludes that mixing various metals in the correct proportions can yield materials with unusual properties, although they may not match the fictional vibranium.

🛠️ Testing the Properties of the Custom Alloy

The host concludes the video by testing the properties of the custom alloy created from 29 different metals. The alloy, which uses iron as a base, also includes chromium, nickel, cobalt, manganese, niobium, vanadium, and a variety of other metals. The host carefully mixes the metals in a crucible and heats them, taking precautions due to the potential for unpredictable reactions. After casting and cooling, the alloy is polished to examine its properties. Tests reveal that the alloy is hard, does not easily spark when polished, indicating corrosion resistance, and exhibits ferromagnetic properties. The host notes that some metals did not mix as well, forming distinct balls within the alloy. The video ends with a thank you to Lucitre for providing metal cubes and an invitation for viewers to like, subscribe, and stay tuned for more interesting content.

Mindmap

Keywords

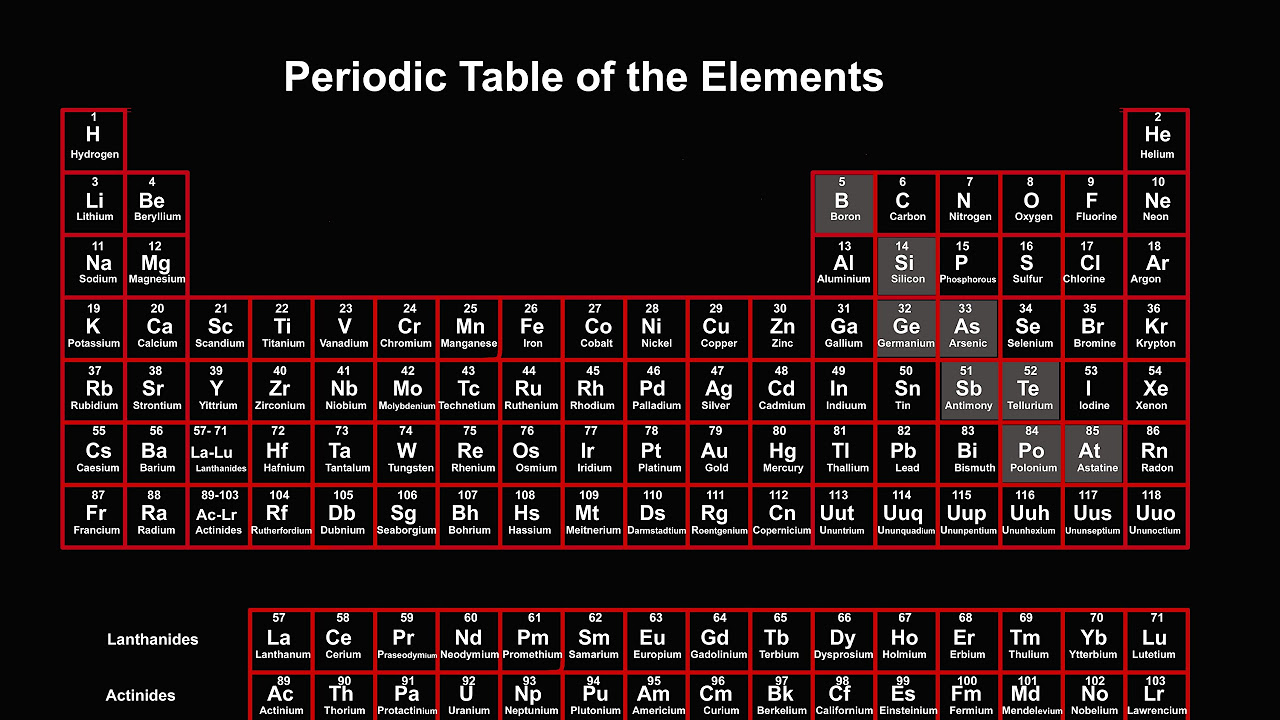

💡Periodic Table

💡Refractory Elements

💡Superalloy

💡Vibranium

💡Brilliant

💡Alloys

💡Bronze

💡Brass

💡Stainless Steel

💡Magnalloy

💡Unico

Highlights

The creator has a new periodic table display case and has collected different metals.

Previous experiments involved melting down refractory elements.

A new experiment is proposed to alloy all the collected metals to see if a super alloy or new material like vibranium can be created.

The video is sponsored by Brilliant, an educational website offering practical problem-solving tools.

The creator recommends Brilliant for its 60 interactive courses in mathematics, natural sciences, and computer science.

Metals in the display case share properties like high density, metallic shine, and high thermal and electrical conductivity.

Different metals have specific uses; for example, iron is hard and cheap, while copper is a good electrical conductor.

Pure metals have disadvantages, leading to the creation of alloys with better properties.

The first metal used by people was copper, and the first copper-based alloy was bronze, initially with arsenic.

A nine percent tin copper alloy (bronze) is being made in the video.

Brass, another copper-based alloy, is made from copper and zinc.

An induction heater is bought for future experiments to melt iron-based alloys.

Stainless steel is made from iron, nickel, and chromium, with chromium protecting against corrosion.

Magnalloy, containing iron and manganese, is used for tank tracks due to its durability.

Ulnico alloy, used in magnets, is made from iron, aluminum, nickel, and cobalt.

An incredible alloy is attempted by alloying 29 different metals, using iron as the base.

The resulting alloy from the mix of metals is quite hard, resistant to corrosion, and has ferromagnetic properties.

The alloy creation process is documented with a focus on safety and the unexpected properties of the mixture.

Lucitre provided metal cubes and elements for the video, and a link to their site is in the video description.

Transcripts

Browse More Related Video

5.0 / 5 (0 votes)

Thanks for rating: