Insulation Resistance Testing

TLDRThe video script discusses the process of insulation resistance testing, a method used to verify the integrity of electrical insulation in various circuits. It explains the use of DC voltage, the importance of disconnecting certain conductors, and the significance of testing at 500 volts DC for systems up to 500 volts. The script highlights the purpose of the test, the expected insulation resistance values, and the steps to perform the test, including dealing with connected loads and potential issues caused by damp environments or faulty equipment. It also warns about the dangers of using the test equipment and emphasizes safety precautions.

Takeaways

- 🔍 The purpose of insulation resistance testing is to verify the condition of the insulation between conductors and ensure it has not been damaged by installation errors or environmental factors.

- ⚡️ For mains voltage circuits, a test voltage of 500 volts DC is typically used, and the minimum acceptable insulation resistance is 1 megohm.

- 🔧 The test should be performed after continuity tests for protective conductors and ring circuits, as indicated in the wiring regulations book.

- 🌐 Disconnecting the neutral and line conductors from the consumer unit is necessary to perform the test, while the protective conductor or earth should remain connected.

- 🔌 Test equipment can vary, with options ranging from single-function devices to multi-function testers, and the correct test voltage setting must be selected according to the circuit's voltage.

- 🛠️ When testing, connect one lead to the earthing of the installation and the other to either the neutral or live conductor, and ensure that no loads are attached to the circuit.

- 💡 For new installations, insulation resistance should be in the hundreds of megaohms, while for older circuits, values around 50 to 100 megaohms are common.

- 🚫 Be cautious of neon indicators in switches that may give misleading results due to their permanent connection to the circuit and the potential for being wired incorrectly.

- 💧 Low insulation resistance values can be caused by damp environments, such as wet plaster or moisture in boxes and fittings.

- 🔥 The first suspects for faults are appliances or installations containing water, such as immersion heaters, boilers, and outdoor lighting.

Q & A

What is the main purpose of insulation resistance testing?

-The main purpose of insulation resistance testing is to verify that the insulation between conductors is in good condition and has not been damaged by careless installation, chewed through, water leakage, or other problems.

What is the typical test voltage for a mains voltage circuit of 230 volts?

-For a mains voltage circuit of 230 volts, the typical test voltage used for insulation resistance testing is 500 volts DC.

What type of voltage is used in resistance testing with a multimeter?

-A very small voltage is used in resistance testing with a multimeter, typically the battery voltage of the multimeter, which is around 9 volts or even smaller.

Why is a higher test voltage required for main circuits?

-A higher test voltage is required for main circuits because certain types of faults simply won't show up if you only apply a few volts to the circuit. Higher voltages help reveal these issues.

What should the insulation resistance be for a new circuit?

-For a new circuit, the insulation resistance should be in the hundreds of megaohms, and it's common to see values even higher than that, depending on the specific installation.

What was the old name for insulation resistance testing and why was it called that?

-The old name for insulation resistance testing was 'mega ring', named after a company called Mega which used to manufacture the equipment for these tests. However, now many different manufacturers produce such equipment.

What is the minimum acceptable insulation resistance according to the Wiring Regulations book?

-According to the Wiring Regulations book, the minimum acceptable insulation resistance for a system with a normal operating voltage up to and including 500 volts is 1 megohm.

What should be done before starting insulation resistance testing?

-Before starting insulation resistance testing, the neutral and line conductors should be disconnected from the consumer unit, and all loads or equipment attached to the circuit should be disconnected.

What are some common causes for low insulation resistance readings?

-Common causes for low insulation resistance readings include wet plaster, damp environments, dirt or grime covering wires, and faulty equipment containing water.

What should one avoid while using insulation resistance testing equipment?

-One should avoid touching the test probes with their fingers while the equipment is active, as it can deliver a shock, even though the current is very low.

What are some items to check first if there's a fault indicated by insulation resistance testing?

-If a fault is indicated by insulation resistance testing, one should first check items that contain water or could be in contact with water, such as immersion heaters, boilers, and outside lighting.

Outlines

🔍 Introduction to Insulation Resistance Testing

This paragraph introduces the concept of insulation resistance testing, which involves applying a DC voltage to verify the integrity of insulation between live conductors and earth. It explains the use of a higher test voltage (500 volts DC) for mains voltage circuits and the purpose of detecting faults that may not be revealed with lower voltages. The importance of insulation resistance in new circuits is highlighted, with expectations of readings in the hundreds of megaohms.

🔌 Disconnecting Conductors for Testing

This section details the procedure of disconnecting neutral and line conductors from consumer units for the purpose of insulation resistance testing. It emphasizes the necessity of keeping the protective conductor or earth connected to the installation during testing. The paragraph also discusses the use of testing equipment and the importance of not attaching any loads to the circuit during testing.

💡 Ensuring Circuit Integrity Before Testing

The paragraph discusses the importance of removing all lamps, unplugging appliances, and ensuring switches are in the on position before conducting insulation resistance testing. It also addresses the need to check for and disconnect any permanently wired equipment, TV amplifiers, and outside lights to ensure accurate test results. The potential issues with neon indicators in switches are also mentioned, which could lead to misleading test results.

🌧️ Interpreting Insulation Resistance Values

This section explains the interpretation of insulation resistance values, with a minimum acceptable value of 1 megohm. It provides guidance on what to expect from new and old circuits, the impact of moisture and dirt on insulation resistance, and the importance of cleaning and maintaining electrical systems to maintain high insulation resistance values.

⚠️ Common Causes of Low Insulation Resistance and Safety Reminder

The paragraph identifies common causes of low insulation resistance, such as water heaters, boilers, and outside lighting exposed to the elements. It advises on immediate actions to take when circuits are frequently tripping, focusing on appliances and systems that contain or are in contact with water. The paragraph concludes with a safety reminder about the use of testing equipment, cautioning against holding test probes during use to avoid electric shock.

Mindmap

Keywords

💡Insulation Resistance Testing

💡DC Voltage

💡Mains Voltage Circuit

💡Multimeter

💡Wiring Regulations

💡Protective Conductors

💡Consumer Unit

💡Earthing

💡Continuity Testing

💡Megaohms

💡Dampness

Highlights

The importance of insulation resistance testing to verify the condition of insulation between conductors.

The use of DC voltage for testing as opposed to the AC voltage used in normal circuit operation.

The recommended test voltage of 500 volts DC for circuits operating up to 500 volts AC.

The purpose of insulation resistance testing is to detect damage due to installation issues or environmental factors.

The use of a multimeter for measuring resistance with a lower voltage compared to the higher voltage used in insulation resistance testing.

The expectation of insulation resistance in the hundreds of megaohms for new circuits.

The historical reference to 'mega ring' tests and the evolution of testing equipment manufacturers.

The sequence of testing, with insulation resistance testing typically following continuity tests.

The necessity of disconnecting neutral and line conductors from the consumer unit for accurate testing.

The importance of keeping the protective conductor or earth connected during testing.

The procedure for insulation resistance testing as outlined in the wiring regulations book.

The minimum acceptable insulation resistance value of 1 megohm for systems operating up to 500 volts AC.

The potential for higher insulation resistance values in reality than the minimum specified in tables.

The need to remove or isolate any loads or equipment connected to the circuit being tested.

The specific testing procedure involving connecting the test equipment to the earth and neutral or line conductors.

The option to test with equipment connected by joining the neutral and line conductors together.

The cautionary advice against holding test probes onto wires during use due to the risk of electric shock.

Transcripts

Browse More Related Video

Continuity test |Explained

Tests for Ring Final Circuits

Why The Clamp Meter Is The Only Tester You Need | Pros and DIYers

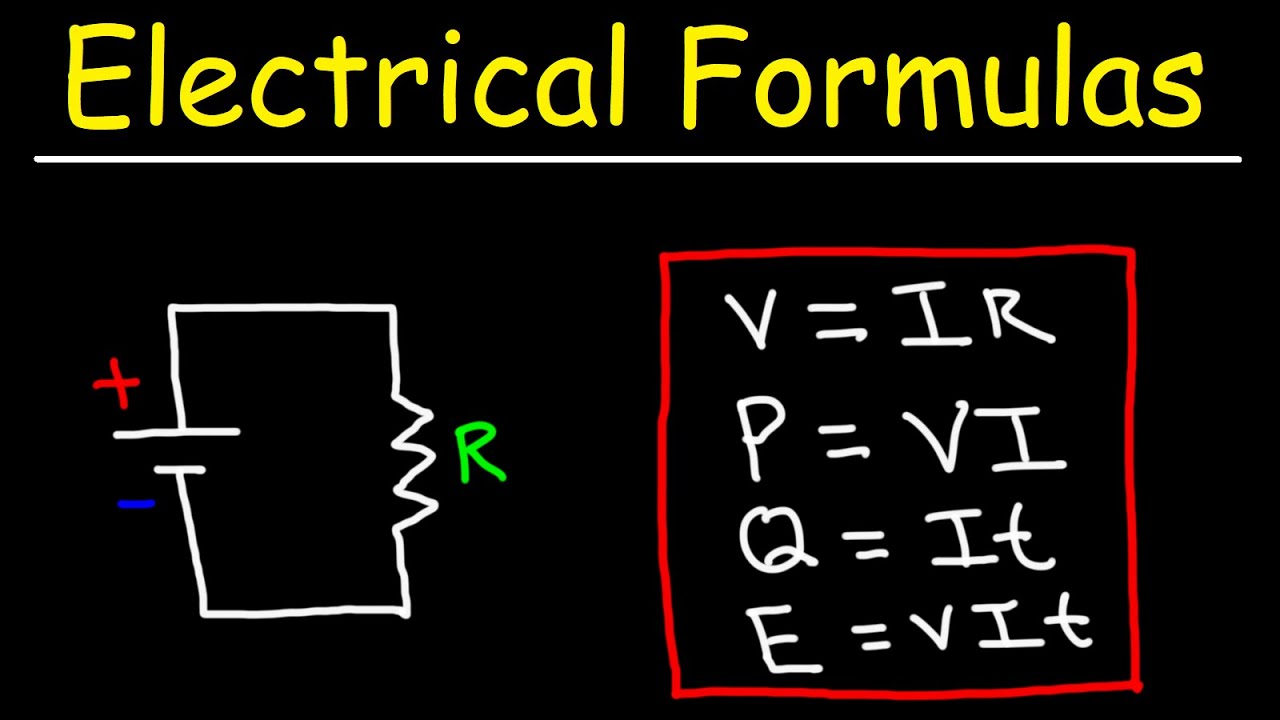

Electrical Formulas - Basic Electricity For Beginners

फेज, न्यूट्रल और अर्थ में अंतर Phase, Neutral And Earthing Wire | Khan GS Research Centre

How to use a Multimeter for beginners: Part 1 - Voltage measurement / Multimeter tutorial

5.0 / 5 (0 votes)

Thanks for rating: