Cómo Hacer BENCENO. Un Disolvente Cancerígeno a partir de un Conservante Alimentario

TLDRThis video script details a DIY chemistry experiment on synthesizing benzene from sodium benzoate and sodium hydroxide at room temperature. It covers the chemical properties of benzene, its industrial uses, and its health risks. The script guides viewers through the process of dry distillation, purification steps including washing with sulfuric acid and sodium hydroxide, and drying with calcium chloride and metallic sodium. The final yield and purity of benzene are discussed, along with safety tips and disposal of chemical waste.

Takeaways

- 🔬 The video discusses the synthesis of benzene using sodium benzoate and sodium hydroxide through a dry distillation process.

- 📝 Benzene is a volatile, flammable, colorless liquid with the chemical formula C6H6 and is the simplest aromatic hydrocarbon.

- 🌟 Benzene is known for its sweet, distinctive smell and is used as a solvent and reactant in laboratories for creating other molecules.

- 🏭 Industrially, benzene is used in the production of plastics, resins, synthetic fibers like nylon, and as an additive in gasoline to prevent knocking.

- ⚠️ Benzene is classified as a carcinogen and is toxic; prolonged exposure can lead to bone marrow issues, so handling it requires caution.

- 📉 Due to its toxicity, the use of benzene has been decreasing in industry and laboratories, with gasoline benzene content limited to 1% or less in some countries.

- 🚭 One of the main sources of human exposure to benzene is tobacco smoke, which contains various harmful substances.

- 🧪 The synthesis process involves grinding sodium benzoate and sodium hydroxide into a fine powder, mixing them, and performing dry distillation in a metal container.

- 🌡️ Purification of the synthesized benzene includes multiple steps such as decantation, washing with distilled water, and drying with calcium chloride and sodium metal.

- 🧴 The final step of purification involves distillation to obtain pure benzene, with the collected fraction boiling at around 80 degrees Celsius.

- 🗑️ The video also addresses the proper disposal of chemical waste generated during the synthesis, emphasizing safety and environmental responsibility.

Q & A

What is the main purpose of the video described in the script?

-The main purpose of the video is to demonstrate the process of synthesizing benzene from sodium benzoate at room temperature, with a focus on the chemical reactions and purification methods involved.

What is benzene and why is it significant in the context of the video?

-Benzene is a colorless, highly volatile, and flammable liquid with the chemical formula C6H6. It is a simple aromatic hydrocarbon and is significant in the video as it is the end product of the synthesis process described.

What are some common uses of benzene mentioned in the script?

-Benzene is used as a solvent and reactant in laboratories, for creating other molecules, in the production of plastics, resins, synthetic fibers like nylon, and as an additive in gasoline to prevent knocking in engines.

Why is benzene considered toxic and a carcinogen?

-Benzene is classified as a carcinogen due to its long-term exposure potentially causing bone marrow issues and other health problems. It is toxic, and while a single exposure is unlikely to be fatal, prolonged exposure can lead to significant health issues.

What is the role of sodium benzoate in the synthesis of benzene as described in the script?

-Sodium benzoate, with the chemical formula C6H5CO2Na, serves as the starting material for the synthesis. It is a chemical compound mainly used as a preservative, and in this case, it undergoes a decarboxylation reaction with sodium hydroxide to produce benzene and sodium carbonate.

How is the benzene produced in the video purified?

-The benzene is purified through several steps including distillation, washing with water to remove impurities, drying with calcium chloride, and further purification using concentrated sulfuric acid and sodium metal to remove water and other impurities.

What is the significance of the decarboxylation reaction in the synthesis of benzene?

-The decarboxylation reaction is significant as it involves the removal of a CO2 group from the sodium benzoate, resulting in the formation of benzene. This reaction is a key step in the synthesis process described in the script.

Why is the use of a metal container recommended for the synthesis process?

-A metal container is recommended because the reaction involves sodium hydroxide, which can attack glass at the high temperatures used in the process, potentially causing the glass container to shatter.

What safety precautions are mentioned in the script regarding the handling of benzene?

-The script mentions that due to benzene's toxicity, care should be taken to limit exposure when working with it. Additionally, the use of personal protective equipment and proper disposal of chemical waste are implied as important safety measures.

What is the final yield of benzene after the purification process as described in the script?

-The final yield of benzene after the purification process is approximately 62%, considering both the synthesis and purification steps.

How is the residual waste from the synthesis process handled according to the script?

-The script mentions that the waste produced during the synthesis cannot be disposed of in regular trash or down the drain. Instead, the waste should be treated properly, and the script provides information on waste treatment in the video description.

Outlines

🔬 Benzene Synthesis from Sodium Benzoate

The script introduces the process of synthesizing benzene from sodium benzoate, a common preservative. Benzene is described as a volatile, flammable, and colorless liquid with a simple aromatic hydrocarbon structure, C6H6. It is used in laboratories as a solvent and reactant, and industrially in the production of plastics, resins, and synthetic fibers like nylon. The video aims to create benzene using sodium benzoate and sodium hydroxide, highlighting the need for safety due to benzene's carcinogenic properties and its decreasing use due to health concerns.

🔥 Benzene Distillation Process

This paragraph details the distillation process of benzene. It starts with the reaction between sodium benzoate and sodium hydroxide, which produces a white vapor and eventually benzene with a turbid, orange color due to reaction byproducts. The script emphasizes the importance of controlling the gas to prevent the vapor from reaching the collection flask and the need for cooling to condense the benzene. The reaction is described as a decarboxylation process, and alternatives to sodium hydroxide are mentioned. The benzene collected is impure and requires further purification steps.

🧪 Purification and Drying of Benzene

The script outlines the purification of impure benzene through a series of steps. Initially, the benzene is transferred to a decantation funnel where water is removed, and additional distilled water is added for further purification. The benzene is then dried using calcium chloride before being filtered and transferred to a clean flask. The benzene is further purified by adding concentrated sulfuric acid, which reacts with impurities, turning the mixture yellow. The benzene is then heated with the sulfuric acid mixture, and precautions are taken to prevent evaporation and ensure safety.

🌡 Final Steps in Benzene Purification

The final paragraph describes the completion of the benzene purification process. After reacting with sulfuric acid, the benzene is separated from the acid and washed multiple times with distilled water and a sodium hydroxide solution to remove residual acid and reaction byproducts. The benzene is then dried using metallic sodium, which reacts with any remaining water to produce hydrogen gas, leaving dry benzene. The final yield is calculated, and the script concludes with a discussion on the efficiency of the process and the handling of byproducts, emphasizing responsible disposal methods.

Mindmap

Keywords

💡Benzene

💡Benzoate of Soda

💡Sodium Hydroxide

💡Decarboxylation

💡Distillation

💡Aromatic Hydrocarbons

💡Toxicity

💡Purification

💡Sulfuric Acid

💡Calcium Chloride

💡Metallic Sodium

Highlights

The video discusses the synthesis of benzene using sodium benzoate, a method that is both innovative and practical for educational purposes.

Benzene is highlighted as a highly volatile and flammable liquid with a sweet, distinctive smell, and is a simple aromatic hydrocarbon.

The video explains the industrial uses of benzene, including its role in manufacturing plastics, resins, synthetic fibers like nylon, and as an additive in gasoline to prevent knocking.

Benzene's classification as a carcinogen and its toxic nature are discussed, emphasizing the need for careful handling and exposure limitation.

The process of dry distillation is introduced, which involves heating solid reactants without dissolving them, crucial for the synthesis of benzene.

The use of a kitchen blender to grind the reactants into a fine powder is an unconventional yet effective method demonstrated in the video.

Safety precautions, such as cooling the blender and using a metal container for the reaction, are emphasized to prevent accidents.

The video details the chemical reaction between sodium benzoate and sodium hydroxide, resulting in the formation of benzene and sodium carbonate.

A purification process involving decantation, washing with distilled water, and drying with calcium chloride is described to remove impurities from the synthesized benzene.

The use of concentrated sulfuric acid to further purify benzene by reacting with impurities, resulting in a color change, is demonstrated.

The video shows the process of washing the benzene with water and sodium hydroxide solution to remove residual acid and reaction byproducts.

Dry distillation using metallic sodium to chemically remove water and other impurities from benzene is introduced as a final purification step.

The importance of using a reflux technique during the drying process to prevent evaporation of benzene is explained.

The video concludes with a discussion on the final yield of purified benzene and the overall efficiency of the synthesis and purification process.

Environmental considerations and the proper disposal of chemical waste generated during the synthesis are briefly mentioned.

The video provides a comprehensive guide on the synthesis of benzene, including detailed steps, safety measures, and purification techniques.

Transcripts

Browse More Related Video

Introduction to Double Replacement Reactions

Solution Stoichiometry - Finding Molarity, Mass & Volume

BTEC Applied Science: Unit 1 Chemistry Calculating Masses in Reactions

Arrhenius definition of acids and bases | Biology | Khan Academy

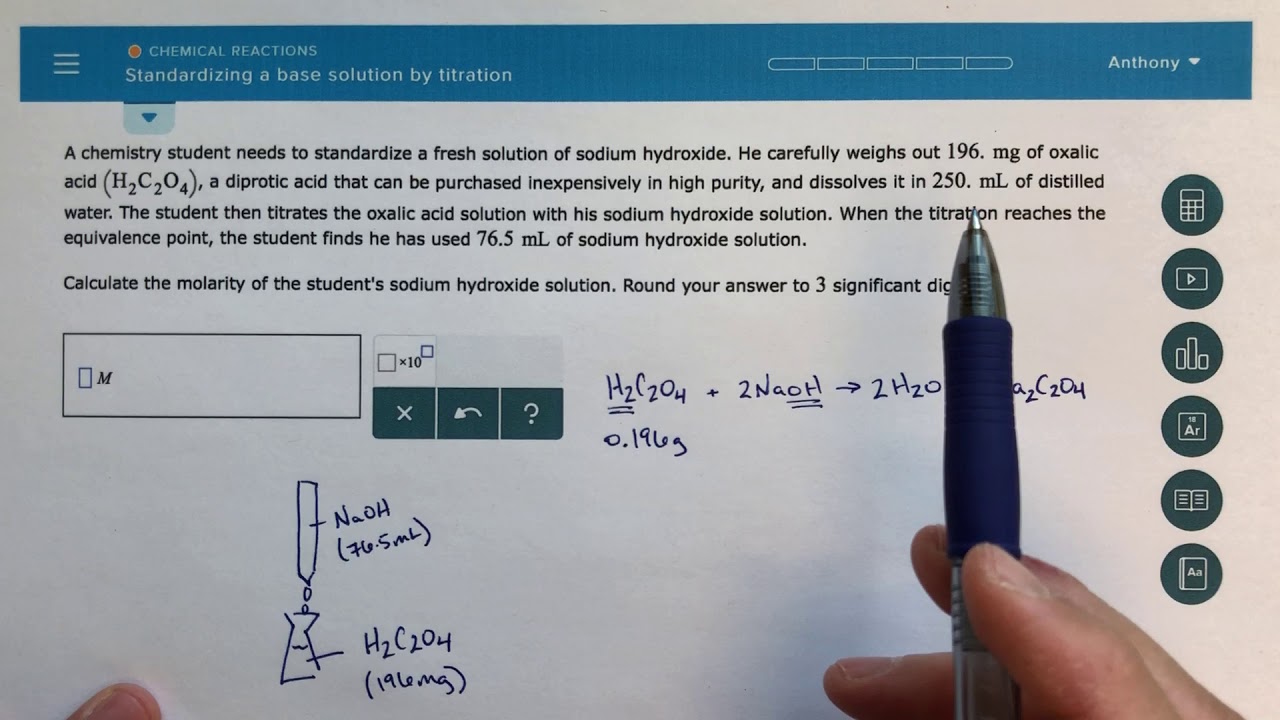

ALEKS - Standardizing a Base Solution by Titration

Experiment 10: Conductivity of Ionic and Covalent Compounds

5.0 / 5 (0 votes)

Thanks for rating: