Ep19 Crystallization and crystalline microstructure - UCSD NANO 134 - Darren Lipomi

TLDRThis script delves into the properties and behaviors of semicrystalline polymers, highlighting the differences between amorphous and crystalline domains. It discusses thermal transitions, including glass transition and melting points, and the thermodynamics of crystallization. The importance of molecular symmetry, intermolecular forces, and sufficient molecular motion for crystallization is emphasized. The script also touches on the impediments to crystallization, such as high molecular weights and branching, and explores the kinetics of crystallite growth, the effects of thermal history, and the unique morphologies of crystallites, including spherulites and their growth patterns.

Takeaways

- 🧊 Crystallization in semicrystalline polymers involves both amorphous and crystalline domains with different thermal and mechanical properties.

- 🔬 Amorphous domains are less dense due to fewer van der Waals interactions, while crystalline domains are denser due to closer molecular packing.

- 🌡️ Different thermal transitions describe the amorphous and crystalline domains: glass transition temperature (Tg) for amorphous domains and crystallization/melting temperatures for crystalline domains.

- 🌀 Delta G of crystallization is determined by Delta H (enthalpy) and T Delta S (entropy). Symmetrical chains and order enhance crystallization by maximizing van der Waals interactions.

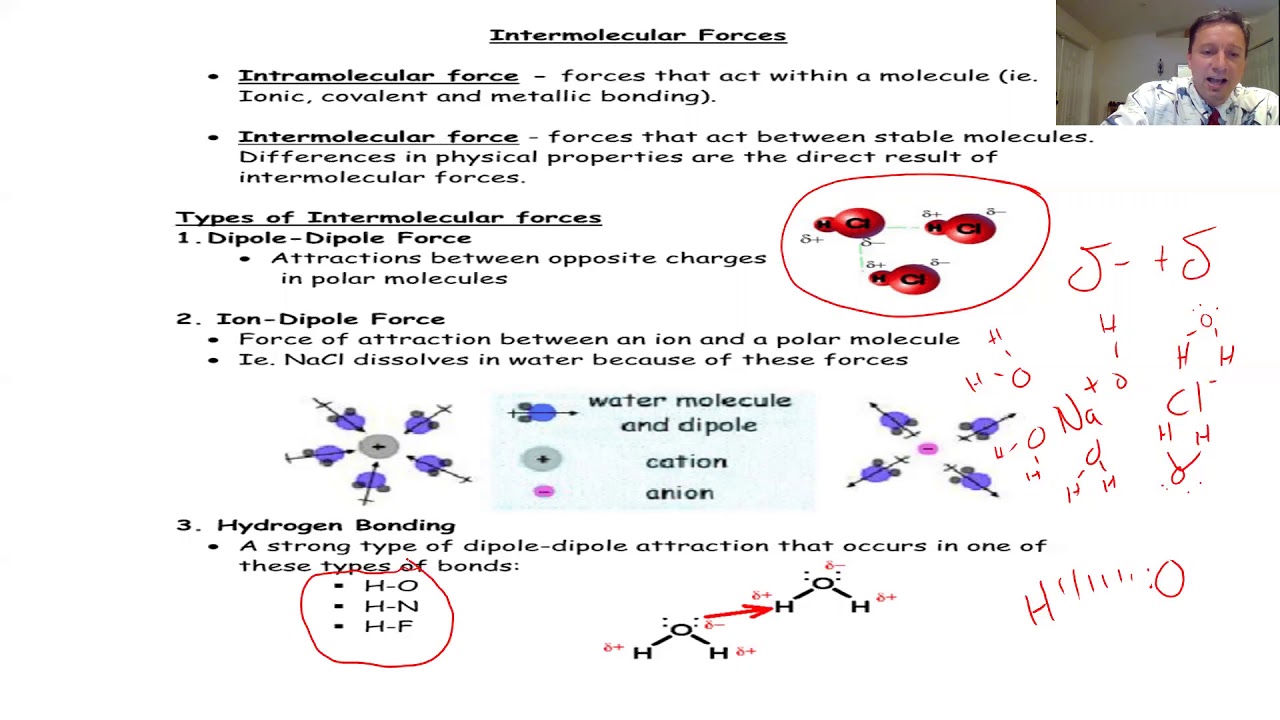

- 🔗 Specific intermolecular forces, like hydrogen bonding, can stabilize chain alignment and facilitate crystallization.

- 🌡️ Sufficient molecular motion is needed for crystallization, typically at temperatures above Tg but below the melting temperature (Tm).

- 📈 Crystallization involves nucleation and growth stages. Nucleation can be stimulated by thermal fluctuations, impurities, or the presence of a smooth surface.

- ⏳ High molecular weights can impede crystallization due to polymer entanglements.

- 🌐 Spherulites are radially growing structures formed during crystallization, often visualized under cross-polarized light as Maltese crosses.

- 🔍 Polyethylene and Teflon (PTFE) demonstrate different melting behaviors due to differences in their entropy of melting and intermolecular forces, influenced by the flexibility and size of hydrogen and fluorine atoms respectively.

Q & A

What are the two domains present in a semicrystalline polymer sample?

-In a semicrystalline polymer sample, there are amorphous domains and crystalline domains.

How do the densities of amorphous and crystalline domains compare?

-Amorphous domains are less dense than crystalline domains because they have less saturated van der Waals contacts with nearby molecules.

What thermal transitions describe the amorphous and crystalline domains?

-The amorphous domains are described by the glass transition temperature (Tg), and the crystalline domains are described by the crystallization temperature (Tc) and the melting temperature (Tm).

What is necessary for achieving high-density crystalline structures?

-Symmetrical chains and order are necessary for close packing of molecules to maximize van der Waals interactions.

What role do intermolecular forces like hydrogen bonding play in crystallization?

-Intermolecular forces such as hydrogen bonding help stabilize the alignment of chains, facilitating the formation of crystalline structures.

Why is molecular motion important in the crystallization process?

-Sufficient molecular motion is needed to allow chains to be recruited to crystalline domains, but not too much motion, which would cause the chains to leave the crystalline structure.

What are the two stages of crystallization?

-The two stages of crystallization are nucleation and growth.

What factors can impede crystallization?

-Crystallization can be impeded by high molecular weights due to entanglements, which slow down the process.

How does temperature affect the growth rate of crystallites in isotactic polystyrene?

-The growth rate of crystallites increases as the temperature decreases from the melting point, reaches a peak, and then decreases again as the temperature approaches the glass transition temperature (Tg).

Why doesn't a polymer sample become 100% crystalline?

-A polymer sample doesn't become 100% crystalline due to factors like polydispersity, branching, and irregularities in the molecular structure that disrupt the crystalline order.

How does the thermal history of a polymer affect its melting behavior?

-The thermal history affects the size and distribution of crystallites, which in turn influences the melting temperature and the range over which the melting occurs.

What is the difference between the enthalpic and entropic contributions to the melting temperature of polymers like polyethylene and Teflon?

-Polyethylene has a higher entropy of melting due to its flexible chains, resulting in a lower melting temperature despite weaker intermolecular forces. Teflon has lower entropy of melting due to its less flexible chains, leading to a higher melting temperature despite stronger intermolecular forces.

What are spherulites in the context of polymer crystallization?

-Spherulites are radially symmetric structures formed during the crystallization of polymers, where crystalline regions grow outward from nucleation sites.

How does branching affect the crystallization and melting of polymers?

-Branching reduces the temperature at which crystallites melt and impedes the formation of large crystallites, resulting in a broader melting range.

Outlines

🔬 Understanding Crystallization in Semicrystalline Polymers

This paragraph delves into the concepts of crystallization in semicrystalline polymer samples, explaining the distinctions between amorphous and crystalline domains. It covers their different thermal and mechanical properties, emphasizing the density differences due to van der Waals interactions. Key points include the glass transition temperature for amorphous domains, the crystallization and melting temperatures for crystalline domains, and the factors influencing crystallization, such as symmetrical chains and specific intermolecular forces like hydrogen bonding.

🌡️ Molecular Motion and Crystallization

This paragraph focuses on the role of molecular motion in crystallization, highlighting the importance of temperature in providing sufficient molecular motion. It explains the temperature ranges for optimal crystallization, the impact of molecular weight on crystallization, and the two stages of crystallization: nucleation and growth. The discussion also touches on how impurities and thermal fluctuations can trigger nucleation events, and the competition between nucleation and chain redispersion during crystallization.

❄️ Supercooling and Nucleation in Crystallization

This paragraph describes an experiment involving supercooling of water in a smooth glass flask to illustrate nucleation. It explains how the absence of nucleation sites prevents crystallization despite being below freezing temperature and how introducing density fluctuations can induce crystallization. The paragraph further discusses the growth of crystallites, the factors influencing their growth rate, and the conditions under which crystallization occurs optimally.

🔥 Thermal History and Crystallization Kinetics

This paragraph examines the effect of thermal history on crystallization, explaining that complete crystallization is rarely achieved due to factors like polydispersity and branching. It discusses the role of small crystallites in melting at lower temperatures and the broadening of melting temperature due to size confinement effects. The paragraph also covers the importance of annealing in achieving nearly complete crystallization and how thermal history influences crystallization kinetics.

⚙️ Melting and Volume Changes in Crystallization

This paragraph addresses the relationship between melting and volume changes in polymers, noting exceptions like water. It explains how thermal history affects melting behavior, the necessity of annealing for optimal crystallization, and the influence of branching on melting temperature. The discussion includes an example involving specific volume versus temperature for polyethylene samples, highlighting the impact of branching on crystallization.

🔧 Thermodynamics of Melting in Polymers

This paragraph explores the thermodynamic principles of melting in polymers, defining the equilibrium melting temperature and the relationship between enthalpy and entropy changes upon melting. It compares the melting behaviors of polyethylene and poly(tetrafluoroethylene) (Teflon), explaining the influence of intermolecular forces and entropy on their melting temperatures. The paragraph highlights the greater entropy change in polyethylene due to its flexible structure compared to Teflon.

🔬 Structural Differences Between Polyethylene and Teflon

This paragraph contrasts the molecular structures of polyethylene and Teflon, focusing on their behavior in the crystalline and melt phases. It explains how the presence of fluorine atoms in Teflon results in a less flexible structure compared to the hydrogen atoms in polyethylene. The discussion includes the impact of these structural differences on the entropy of the melt state and the resulting melting temperatures of the two polymers.

📏 Molecular Flexibility and Melting Entropy

This paragraph delves into the relationship between molecular flexibility and melting entropy, using the example of polyethylene and Teflon. It explains how the covalent radius of fluorine in Teflon restricts molecular flexibility, leading to a higher energy barrier for rotational freedom compared to polyethylene. The paragraph also discusses the implications of this difference for the entropy of the melt state and the melting temperatures of the polymers.

🔍 Crystalline Morphologies in Polymers

This paragraph describes the formation and structure of crystalline morphologies in polymers, particularly the nucleation and radial growth of spherulites. It explains how these spherulites form under cross-polarized light, resulting in distinctive patterns due to anisotropy. The discussion covers the internal structure of spherulites, including the arrangement of crystalline and amorphous regions and the role of molecular axes in determining crystallite orientation.

🔄 Conformations in Polymer Crystallization

This final paragraph explores the different conformations of polymer chains in crystallites, comparing regular folding with the disordered switchboard model. It explains how these conformations affect the structure of spherulites, with adjacent re-entry being more common in solution-grown crystals and the switchboard model favored in spherulites. The paragraph concludes by summarizing the key points of the discussion on polymer crystallization and thanking the audience.

Mindmap

Keywords

💡Crystallization

💡Amorphous Domains

💡Crystalline Domains

💡Glass Transition Temperature

💡Crystallization Temperature

💡Delta H of Crystallization

💡Delta S of Crystallization

💡Van der Waals Interactions

💡Nucleation

💡Growth of Crystals

Highlights

Crystallization involves both amorphous and crystalline domains with distinct thermal and mechanical properties.

Amorphous domains are less dense due to fewer saturated Van der Waals contacts, whereas crystalline domains are more densely packed.

Crystalline domains exhibit different thermal transitions, such as glass transition temperature for amorphous domains and crystallization and melting temperatures for crystalline domains.

Thermodynamics of crystallization includes delta G (Gibbs free energy), delta H (enthalpy), and delta S (entropy) terms.

Symmetrical chains and order are essential for effective crystallization.

Vander Waals interactions are stronger at closer molecular packing, crucial for crystallization.

Hydrogen bonding and specific intermolecular forces can stabilize alignment and promote crystallization.

Sufficient molecular motion is required for crystallization, ideally around 30 degrees above the glass transition temperature but not too close to the melting temperature.

Crystallization can be impeded by high molecular weights due to entanglements.

Crystallization has two stages: nucleation (order stimulated by intermolecular forces) and growth (recruitment of chains to the nucleus).

Nucleation can be triggered by thermal fluctuations and the presence of impurities.

Growth rate of crystallites is dependent on temperature, with a peak at an optimal range.

Melting temperature and crystallization kinetics are influenced by the polymer's thermal history and morphology.

Branching in polymers restricts crystallization and affects melting behavior.

Polyethylene and Teflon show different melting behaviors due to their respective molecular structures and entropy changes.

Crystalline morphologies nucleate and grow radially, forming structures called spherulites.

Spherulites exhibit unique morphologies and can be observed under cross-polarized light, showing a Maltese cross pattern.

Crystallites within spherulites can have adjacent re-entry or switchboard configurations, influencing their overall structure.

Transcripts

Browse More Related Video

5.0 / 5 (0 votes)

Thanks for rating: