Recrystallization and Melting Point Analysis

TLDRThis educational video, sponsored by Thermo Fisher Scientific, introduces the technique of recrystallization for purifying solid products in a laboratory setting. It explains the process of dissolving impure substances in a hot solvent to release impurities, followed by cooling to recrystallize the pure product. The tutorial covers the necessary materials, the importance of selecting an appropriate solvent, and the steps to perform recrystallization, including hot filtration, cooling, and separation of crystals. It also discusses methods to test purity, such as melting point analysis and percent recovery, and provides tips for improving crystallization, like using a seed crystal or roughening the beaker surface.

Takeaways

- 🔬 Thermo Fisher Scientific offers a wide range of reagents and materials for various laboratory applications.

- 🧪 Thermo Fisher has over 80,000 laboratory chemicals available on one site, ensuring choice, quality, and supply assurance.

- 🔍 Recrystallization is a purification technique used to separate impurities from a solid product.

- 🌡️ The process involves dissolving an impure product in a hot solvent and then cooling it to crystallize the pure product.

- ⚗️ Essential materials for recrystallization include beakers, a hot plate, a stir bar, a vacuum filtration setup, a powder funnel, and a watch glass.

- 💧 Distilled water is often used as a recrystallization solvent to avoid introducing additional impurities.

- 🧴 During recrystallization, impurities remain dissolved in the solvent while the pure product crystallizes out.

- 🧊 Cooling the solution slowly and using an ice bath can help ensure complete crystallization of the product.

- 📉 The purity of the recrystallized product can be assessed by comparing its melting point range with the original impure sample and literature values.

- 💡 Techniques such as using a glass rod to scrape the beaker or adding seed crystals can help initiate crystallization if needed.

Q & A

What company sponsors the video and what do they offer?

-Thermo Fisher Scientific sponsors the video, offering a wide range of reagents and materials for laboratory applications, including research, drug discovery and development, and manufacturing.

What is recrystallization and why is it used?

-Recrystallization is a purification technique that separates impurities from a solid product by taking advantage of differences in solubility. It is used to purify solid products that may contain impurities incorporated during the reaction.

What materials are needed for the recrystallization process?

-Materials needed include two beakers (250 ml and 150 ml), a hot plate with a magnetic stirrer or a Bunsen burner, a stir bar, a stirring rod, a vacuum filtration setup, a powder funnel, a watch glass, disposable pipettes, and the impure product (benzoic acid in this case) with distilled water as the solvent.

Why is distilled water chosen as the solvent for recrystallization in this example?

-Distilled water is chosen because benzoic acid has high solubility in boiling water and low solubility in room temperature water, making it a good solvent for recrystallization. Distilled water is used to avoid introducing additional impurities from tap water.

What is the importance of using the minimum amount of solvent during recrystallization?

-Using the minimum amount of solvent is important because it ensures that the product will precipitate out of the solution effectively as it cools, leading to a purer final product.

What steps are involved in the hot filtration process?

-Hot filtration involves heating the solution to ensure the solid dissolves completely, then filtering out any insoluble impurities while the solution is still hot to avoid losing any of the desired product.

What are two methods to initiate crystallization if crystals do not form naturally?

-Two methods to initiate crystallization are scraping the glass surface of the beaker with a glass rod to create nucleation sites and adding a few pure crystals of the product to act as seed crystals.

How can the purity of the recrystallized product be tested?

-The purity can be tested by measuring the melting point of the recrystallized product and comparing it to the melting point of the original impure sample and the literature value. A purer product will have a narrower melting point range.

What is the significance of percent recovery in recrystallization, and how is it calculated?

-Percent recovery indicates the efficiency of the recrystallization process. It is calculated by dividing the mass of the purified sample by the mass of the original sample and multiplying by 100. A value less than 100% is expected due to the removal of impurities and some product loss.

What are some advanced recrystallization techniques mentioned?

-An advanced technique involves using a multi-solvent system where the first solvent dissolves the impure product and a second solvent causes the pure product to crystallize gradually. This method is used for more complex recrystallizations.

Outlines

🔬 Thermo Fisher Scientific's Wide Range of Lab Solutions

This paragraph introduces the video sponsor, Thermo Fisher Scientific, highlighting their extensive offerings of reagents and materials. It mentions the support for various laboratory applications, including research, drug discovery, development, and manufacturing. With over 80,000 laboratory chemicals available, Thermo Fisher ensures choice, quality, and supply assurance for all chemical needs. Viewers are encouraged to visit the provided link for more information.

⚗️ Introduction to Recrystallization Technique

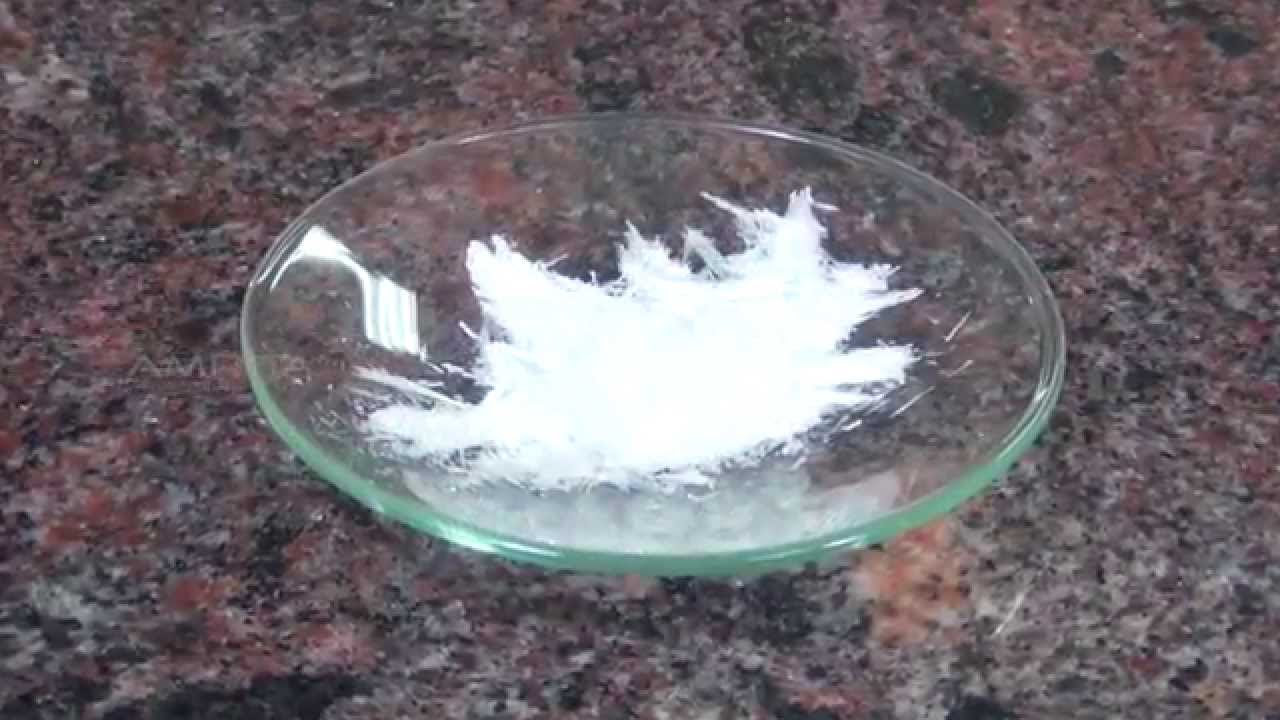

The paragraph explains the concept of recrystallization as a purification technique used to remove impurities from a solid product obtained from a chemical reaction. It discusses how impurities can be incorporated into the lattice structure during precipitation and how recrystallization separates the pure product from these impurities. The process involves dissolving the impure product in a hot solvent, cooling the solution to allow the pure product to crystallize while impurities remain dissolved due to their higher solubility.

🌡️ Step-by-Step Recrystallization Process

This paragraph details the materials and steps required for recrystallization, including beakers, a hot plate, a stirring rod, a vacuum filtration setup, and disposable pipettes. It describes the process of heating distilled water, dissolving the impure product, and ensuring minimum solvent use. The importance of hot filtration to remove insoluble impurities and the gradual cooling of the solution to form pure crystals are emphasized. The paragraph concludes with instructions on separating and drying the crystals using vacuum or gravity filtration.

🧪 Analyzing the Purity of Recrystallized Product

This section covers the methods to assess the purity of the recrystallized product, including melting point analysis and percent recovery calculations. It explains the importance of comparing the melting point range of the purified sample with the impure sample and the reported value, noting that a pure product will have a sharp melting point. The process of measuring the melting point using a melting point tube and apparatus is outlined, and the need to calculate percent recovery to evaluate the efficiency of the recrystallization process is discussed.

🧬 Troubleshooting and Advanced Recrystallization Techniques

The final paragraph addresses potential issues during recrystallization, such as crystals not forming due to smooth beaker surfaces. Solutions include using a glass rod to create nucleation sites or adding seed crystals. It briefly introduces more advanced recrystallization techniques involving multi-solvent systems, where a second solvent causes the pure product to crystallize gradually. The paragraph concludes with a thank you note, encouraging viewers to subscribe, support on Patreon, and contact for more information.

Mindmap

Keywords

💡Recrystallization

💡Solubility

💡Impurities

💡Hot Filtration

💡Melting Point Analysis

💡Vacuum Filtration

💡Seed Crystal

💡Hot Plate

💡Percent Recovery

💡Lattice Structure

Highlights

Introduction to Thermo Fisher Scientific and their range of laboratory chemicals and materials.

Explanation of the importance of separation techniques in laboratory settings.

Introduction to recrystallization as a purification technique for solid products.

Description of how recrystallization removes impurities from a solid by taking advantage of differences in solubility.

Step-by-step guide on setting up and performing recrystallization.

Importance of choosing a suitable recrystallization solvent based on solubility data.

Specific example using benzoic acid and distilled water for recrystallization.

Detailed procedure for dissolving the impure product in hot solvent and cooling it to recrystallize the pure product.

Explanation of hot filtration to remove insoluble impurities.

Guidance on allowing the solution to cool slowly to form pure crystals.

Instructions for using vacuum filtration to separate the crystals from the liquid.

Importance of washing the crystals with pure solvent to remove any remaining impurities.

Procedure for measuring the melting point to test the purity of the recrystallized product.

Explanation of how to calculate the percent recovery of the recrystallized sample.

Tips for troubleshooting recrystallization, such as using a glass rod to initiate crystal growth.

Transcripts

Browse More Related Video

Recrystallization

Purification of Benzoic Acid by Crystallization - MeitY OLabs

Introduction to Recrystallization

Purification of KNO3 using Recrystallization

GCSE Chemistry - Filtration, Evaporation & Crystallisation #6

Natural Products Chemistry - In the Lab: How Do We Figure Out What Our Natural Product Looks Like?

5.0 / 5 (0 votes)

Thanks for rating: