Introduction to Recrystallization

TLDRThis script delves into the principles of recrystallization, a technique for purifying organic crystalline materials. It explains how intermolecular forces drive the process, using a simple analogy with green squares for pure molecules and red triangles for impurities. The script illustrates the importance of slow cooling to ensure thermodynamics favor the formation of pure crystals, as rapid cooling can trap impurities. The goal is high-purity samples, essential for further experimentation or identification.

Takeaways

- 🧬 The recrystallization process is driven by intermolecular forces, which are crucial in purifying organic crystalline materials.

- 🔍 The script uses green squares to represent pure molecules of the compound of interest and red triangles for impurities to illustrate the process.

- 🌡️ To begin recrystallization, a pure crystalline material is dissolved by adding heat, overcoming intermolecular forces to reach a higher free energy state.

- 🔄 The dissolution and recrystallization process involves a change in the free energy of the system, which is depicted in an energy coordinate diagram.

- 📉 Slow cooling of the dissolved sample allows for the reformation of a highly ordered crystal, maximizing intermolecular forces and resulting in a pure sample.

- 🔑 The impurity molecules do not fit well into the crystal lattice, leading to weaker intermolecular forces and a higher free energy state compared to pure crystals.

- 🌟 Recrystallizing an impure sample with slow cooling encourages the formation of a purer crystal as impurities are less likely to adhere to the growing crystal surface.

- 🛑 Rapid cooling during recrystallization can trap impurities within the crystal structure, leading to an impure product, which is undesirable.

- ⏳ Slow cooling is essential for the recrystallization process as it ensures thermodynamics guide the system to its most stable, lowest energy state, resulting in a pure crystal.

- 🔬 The purity of the recrystallized product can be further verified through melting point identification, which will be discussed in a subsequent segment.

- 🔄 The process of recrystallization is a cycle of dissolution and reformation, leveraging the thermodynamics of intermolecular forces for purification.

Q & A

What is the main purpose of the recrystallization process in chemistry?

-The main purpose of the recrystallization process is to purify organic crystalline materials by taking advantage of the differences in intermolecular forces between the compound of interest and impurities.

How are the molecules of the product of interest and impurities depicted in the script's illustrations?

-In the script's illustrations, molecules of the product of interest are depicted as green squares, while impurities are represented as red triangles.

What does the energy coordinate diagram represent in the context of recrystallization?

-The energy coordinate diagram represents the change in free energy of the system as the crystalline material is dissolved and then recrystallized, showing the transition between different states of the material.

Why is it necessary to add heat to dissolve a crystalline sample?

-Heat is added to dissolve a crystalline sample to overcome the intermolecular forces holding the molecules together, allowing the molecules to separate and reach a higher free energy state in solution.

What happens when a pure crystalline material is dissolved and then cooled slowly?

-When a pure crystalline material is dissolved and then cooled slowly, the molecules reassemble into a highly ordered crystal structure with maximized intermolecular forces, essentially returning to the original state.

Why is the free energy of an impure crystal higher than that of a pure crystal?

-The free energy of an impure crystal is higher because the impurity molecules do not fit well into the crystal lattice, leading to weaker intermolecular forces and a less stable state.

How does the recrystallization process lead to a purer product?

-During recrystallization, impurities, which do not interact as strongly with the crystal surface, are more likely to fall off and return to solution, allowing for the formation of a purer crystal.

Why is slow cooling essential during the recrystallization process?

-Slow cooling is essential because it allows thermodynamics to dictate the system's state, favoring the formation of pure, high-quality crystals by ensuring that the most stable free energy state is reached.

What would be the consequence of cooling a solution rapidly during recrystallization?

-Rapid cooling can trap impurities within the crystal structure, as the crystal face grows too quickly for impurities to fall off, resulting in an impure crystal which is not the desired outcome of recrystallization.

How does the recrystallization process relate to the melting point identification of a compound?

-After recrystallization, the purity of the compound is expected to be high, which can be confirmed by its melting point. A pure compound has a sharp and consistent melting point, which is a topic for the next segment mentioned in the script.

Outlines

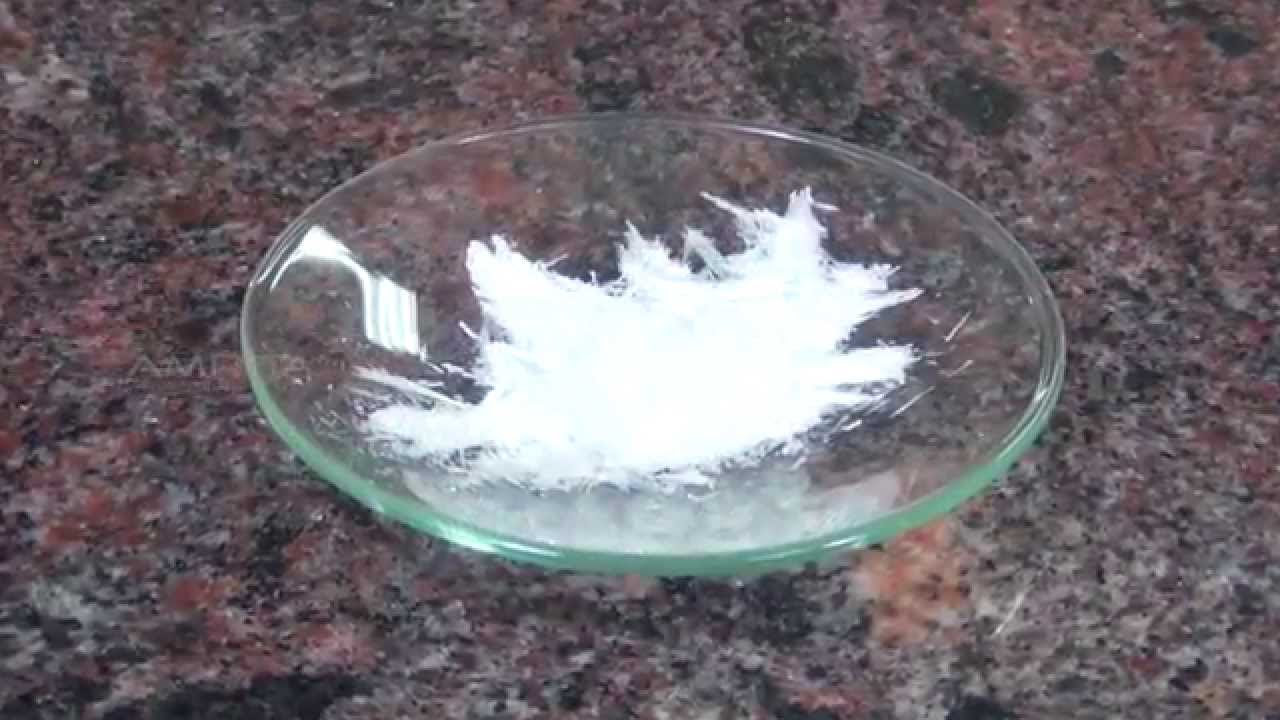

🔬 Recrystallization Process for Purity

This paragraph introduces the recrystallization process, a method for obtaining high purity organic crystalline materials. It explains how intermolecular forces play a crucial role in this process. The discussion begins with the dissolution of a pure crystalline material, overcoming intermolecular forces to increase the system's free energy. Upon slow cooling, the system naturally seeks to return to its most stable, low energy state, resulting in the reformation of a highly ordered crystal of the desired compound. The paragraph uses the analogy of green squares for pure molecules and red triangles for impurities to illustrate the process.

🧊 The Importance of Slow Cooling in Recrystallization

This paragraph emphasizes the significance of slow cooling during the recrystallization process to ensure purity. It contrasts the slow cooling method with rapid cooling, explaining that rapid cooling can trap impurities within the crystal lattice, leading to an impure product. The paragraph illustrates that when a sample with impurities is dissolved and slowly recrystallized, the impurities, which do not fit well in the crystal lattice, are less likely to adhere to the growing crystal surface and thus fall off, allowing for the formation of a purer crystal. The summary highlights the thermodynamic principle that slow cooling allows the system to reach its most stable state, which is a pure crystal, and sets the stage for the next topic on melting point identification.

Mindmap

Keywords

💡Recrystallization

💡Intermolecular forces

💡Purity

💡Crystal lattice

💡Free energy

💡Thermodynamics

💡Impurities

💡Crystal growth

💡Slow cooling

💡Melting point

Highlights

Introduction to the principles of recrystallization for purifying organic crystalline materials.

The role of intermolecular forces in driving the recrystallization process.

Use of molecular models to represent the compound of interest and impurities.

Explaining the thermodynamics of dissolving and recrystallizing a pure material.

The process of disassembling a crystal to the molecular level to overcome intermolecular forces.

The energy state changes during the dissolution and recrystallization of a pure compound.

The formation of a highly ordered crystal from a pure compound due to intermolecular forces.

Utilizing crystalline material behavior to purify an impure sample.

Impurities' compromised intermolecular forces and their impact on the free energy of the crystal.

The expectation of higher purity from recrystallization under stable conditions.

The process of crystal growth and the exclusion of impurities from the crystal lattice.

The importance of slow cooling in the recrystallization process for purity.

Thermodynamics' role in ensuring the most stable free energy state and pure crystal formation.

The consequences of rapid cooling and its effect on trapping impurities within the crystal.

The necessity of slow cooling to allow thermodynamics to drive the formation of pure crystals.

The practical applications of recrystallization for further experimentation or identification by melting point.

Transcripts

5.0 / 5 (0 votes)

Thanks for rating: