Lec-29 I Refractories and Insulators I Applied chemistry I Chemical engineering

TLDRIn this informative lecture, Supruder Yoshi delves into the world of applied chemistry, focusing on semi-porous non-crystalline amorphous materials. He discusses the various types of ceramics, their composition, and diverse applications ranging from kitchenware to high-tech manufacturing. Yoshi further explores refractories and insulators, detailing their properties, classifications, and the contexts in which they are utilized. The lecture provides valuable insights into the role these materials play in industries and scientific applications, emphasizing their importance in withstanding high temperatures and electrical currents.

Takeaways

- 📚 The subject code for Applied Chemistry is 3130506, covering topics like chemical kinetics, phase rule, thermochemistry, and stereochemistry.

- 🏺 Ceramics are non-crystalline, amorphous materials used in various applications such as knife blades, bulletproof jackets, armored vehicles, and food containers.

- 🔍 The chapter on semi-porous non-crystalline, amorphous materials is divided into sections like cements, ceramics, refractories, insulators, and liquid crystals.

- 📈 There are two main types of ceramics: crystalline and non-crystalline, each used based on their specific applications.

- 🔥 Refractories and insulators are materials that are applied in high-temperature environments and electrical systems due to their heat and electrical properties.

- 🌡️ Refractories are inorganic, non-metallic, porous, and heterogeneous minerals that maintain their physical shape and chemical identity at high temperatures.

- 📊 Refractories can be classified into acid, basic, and neutral types, depending on their chemical composition and resistance to acidic or alkaline environments.

- 🏢 The applications of refractories include manufacturing bricks for furnaces, linings for high-temperature equipment, and in scientific instruments.

- 🔄 Acid refractories are stable in acidic environments and examples include silica (SiO2), zirconia (ZrO2), and alumina.

- 🛡️ Basic refractories are stable in alkaline environments and include materials like magnesia, dolomite, and chromite.

- 🌀 Neutral refractories are stable in both acidic and basic environments, with examples such as carbon, graphite, and certain types of chromites and alumina.

Q & A

What is the subject code for Applied Chemistry in the lecture series?

-The subject code for Applied Chemistry is 3130506.

What topics have been covered in the previous sessions of the Applied Chemistry lecture series?

-In the previous sessions, topics such as chemical kinetics, phase rule, thermochemistry, and stereochemistry have been studied.

What is the primary focus of Chapter 8 in the lecture series?

-Chapter 8 focuses on semi-porous non-crystalline, amorphous materials, including ceramics, refractories, insulators, and liquid crystals.

What are the two main types of ceramics mentioned in the lecture?

-The two main types of ceramics discussed are crystalline ceramics and non-crystalline ceramics.

What are some applications of ceramics based on their types?

-Ceramics are used in various applications such as manufacturing knife blades, bulletproof jackets, armored vehicles, and food containers.

What are the three components of refractories and insulators?

-The three components are a mineral aggregate, a binder phase, and additives.

What property allows refractories to be used in high-temperature environments?

-Refractories have the ability to retain their physical shape and chemical identity when subjected to very high temperatures.

How are refractories classified based on their technical composition?

-Refractories are classified into acid refractories, basic refractories, and neutral refractories based on their technical composition.

What are the differences between acid, basic, and neutral refractories in terms of their stability?

-Acid refractories are stable in acidic atmospheres but attacked by alkalis. Basic refractories are stable in alkaline environments but not in acidic ones. Neutral refractories are chemically stable in both acidic and basic atmospheres.

What are the two main classifications of refractories based on physical form?

-Refractories are classified into shaped refractories and unshaped refractories based on their physical form.

What are some examples of unshaped refractories?

-Unshaped refractories include plastic refractories, ramming mixtures, gunning mixes, fettling mixes, and mortars.

How do insulating refractories contribute to energy efficiency?

-Insulating refractories have high porosity and low thermal conductivity, which helps reduce the rate of heat flow and thus reduce heat losses due to their low density.

Outlines

📚 Introduction to Applied Chemistry and Ceramics

This paragraph introduces the lecture series on applied chemistry, led by Supruder Yoshi from the Energy Institute of Engineering and Technology. The subject code 3130506 is mentioned, and the lecture focuses on chapter eight, which discusses semi-porous non-crystalline amorphous materials. The chapter is divided into various segments such as ceramics, refractories, insulators, and liquid crystals. The discussion begins with ceramics, emphasizing their non-crystalline nature and applications in different fields. Two main types of ceramics are highlighted: crystalline and non-crystalline. The lecture also touches on the applications of ceramics in manufacturing items like knife blades, bulletproof jackets, armored vehicles, and food containers.

🔥 Properties and Classification of Refractories

This paragraph delves into the properties and classification of refractories and insulators. Refractories are described as inorganic, non-metallic, porous, and heterogeneous minerals that maintain their physical shape and chemical identity at high temperatures. They serve as thermal and chemical protective barriers. The classification of refractories is based on their technical composition into acid refractories, basic refractories, and neutral refractories. Each type is suitable for different atmospheric conditions and has distinct properties. Examples of each type, such as silica, zirconia, alumina, magnesia, dolomite, and chromite, are provided. The paragraph also introduces the classification based on physical form, distinguishing between shaped and unshaped refractories, with further细分 into standard and special shapes for shaped refractories and various types of unshaped refractories like plastic refractories, gunning mixes, and mortars.

🏗️ Applications and Examples of Refractories

The final paragraph discusses the applications and examples of specific types of refractories. Zirconia refractories, despite their polymorphic nature and challenges in fabrication, are stabilized with elements like calcium and magnesium for use. Aluminum refractories, containing Al2O3, are noted for their chemical stability, hardness, and resistance to corrosion. Insulating refractories, characterized by high porosity and low thermal conductivity, are used to reduce heat flow and losses due to their low density. The summary concludes by wrapping up the current session and looking forward to the next lecture.

Mindmap

Keywords

💡Applied Chemistry

💡Ceramics

💡Refractories

💡Insulators

💡Acid Refractories

💡Basic Refractories

💡Neutral Refractories

💡Shaped Refractories

💡Unshaped Refractories

💡Zirconia Refractory

💡Alumina Refractories

💡Insulating Refractories

Highlights

Introduction to Applied Chemistry with a focus on chemical kinetics, phase rule, thermochemistry, and stereochemistry.

Overview of Chapter 8: Semi-porous non-crystalline, amorphous materials, with a focus on ceramics.

Ceramics are inorganic, containing mineral aggregates, binding phases, and additives, with applications in knife blades, bulletproof jackets, armored vehicles, and food containers.

Distinguishing between crystalline and non-crystalline ceramics based on their application areas.

Introduction to refractories and insulators, highlighting their use in high-temperature furnaces and electric current stations.

Definition of refractories as inorganic, non-metallic, porous, and heterogeneous materials capable of withstanding high temperatures.

Classification of refractories into acid, basic, and neutral based on their chemical composition and interaction with acidic or alkaline environments.

Acid refractories, used in acidic atmospheres, are stable to acids but vulnerable to alkalis.

Basic refractories, ideal for alkaline atmospheres, resist alkaline dust and fumes but are unstable in acidic environments.

Neutral refractories, chemically stable in both acidic and alkaline environments.

Further classification of refractories based on physical form: shaped (standard and special) and unshaped (plastic refractories, ramming mixtures, castables, gunning mixes, patching mixes, and mortars).

Examples of refractories include zirconia, alumina, and insulating refractories, each with unique properties and applications.

Zirconia refractories, polymorphic and stabilized with calcium or magnesium, have fabrication challenges.

Alumina refractories, known for their chemical stability, hardness, and resistance to inorganic acids and superheated steam.

Insulating refractories, characterized by high porosity and low thermal conductivity, aim to reduce heat flow and loss.

Transcripts

Browse More Related Video

Lec-01 I Introduction to Applied chemistry I Applied Chemistry I Chemical Engineering

Lec-32 l NMR Spectroscopy l Applied chemistry | Chemical engineering

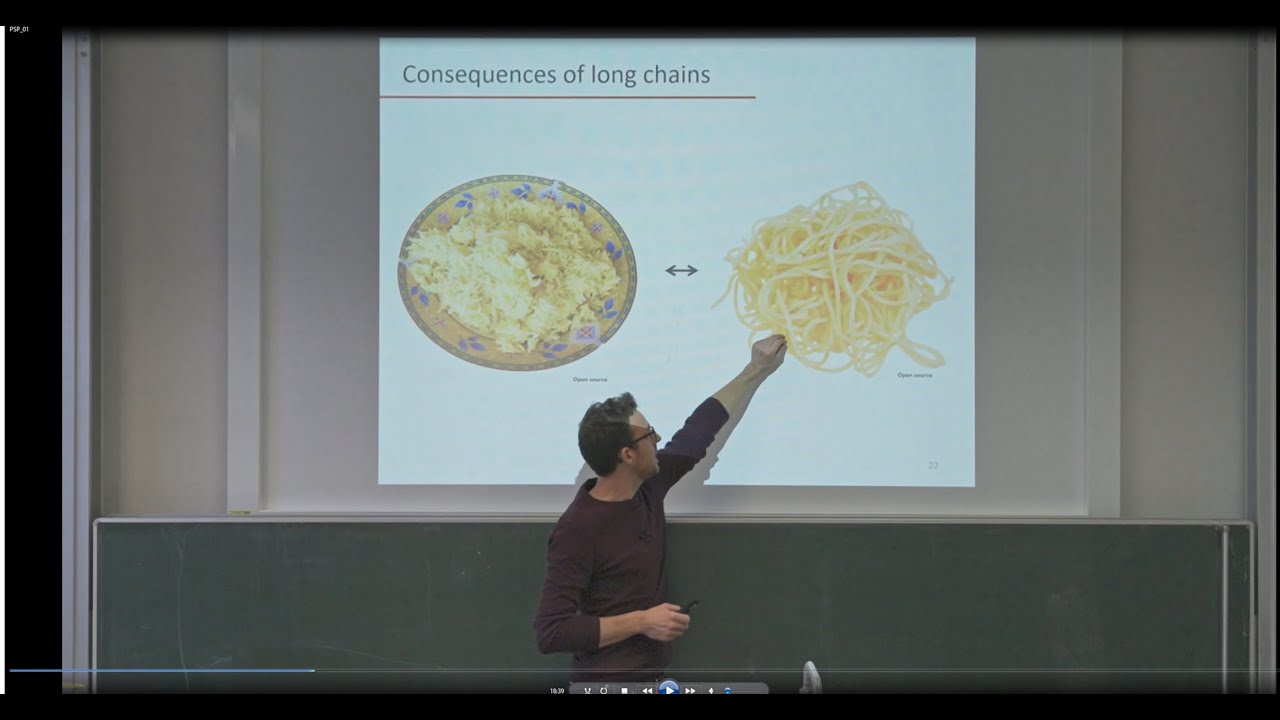

Polymer Science and Processing 01: Introduction

Nobel Prize lecture: Anne L'Huillier, Nobel Prize in Physics 2023

Classification Of Textile Fibers - Sources Of Textile Fibre

Lec-31 | Mass spectrometry | Applied chemistry | Chemical engineering

5.0 / 5 (0 votes)

Thanks for rating: