Condensation Polymerisation | Organic Chemistry | Chemistry | FuseSchool

TLDRThis video script delves into the formation of condensation polymers, contrasting them with addition polymers by highlighting the elimination of small molecules like water during their synthesis. It focuses on two main types: polyamides, exemplified by nylon 6,6, which are used in textiles and engineering due to their strength and low friction properties; and polyesters, with polyethylene terephthalate (PET) being a common example used in plastic bottles and clothing. The script simplifies the complex chemistry by using visual representations, making it accessible to viewers and providing insights into the practical applications of these polymers.

Takeaways

- 🧪 Condensation polymers form through a process that not only creates the polymer but also eliminates a small molecule, typically water.

- 🔗 Polyamides are a type of condensation polymer that includes the amide link, formed by the reaction between a carboxylic acid and an amine.

- 🧵 Nylon 6,6 is a specific example of a polyamide, created by reacting hexane-1,6-diamine with hexanedioic acid, resulting in a strong material used in textiles and engineering.

- 📚 The formation of polyamides can be visually simplified by representing the molecules as rectangular blocks to focus on the functional groups involved in the reaction.

- 🛠 Nylon, as a polyamide, is valued for its structural integrity and low friction properties, making it ideal for applications like bearings and bushes.

- 🍶 Polyesters are another class of condensation polymers, where ester links are formed by the reaction of a carboxylic acid with an alcohol.

- 🧬 The formation of polyethylene terephthalate (PET), a common polyester, involves the reaction between Benzene-1,4-dicarboxylic acid and ethane-1,2-diol, also releasing water.

- 🥤 PET is widely recognized for its use in the production of plastic bottles for beverages.

- 👗 Polyester is also used to make fabrics for clothing, highlighting its versatility in different applications.

- 📘 Understanding condensation polymers involves recognizing the types of monomers involved, the types of links formed, and the applications of the resulting polymers.

- 🔍 The script provides a clear explanation of how condensation polymers are formed, with a focus on the formation and uses of polyesters and polyamides.

Q & A

What is the main difference between condensation polymers and addition polymers?

-Condensation polymers form with the elimination of a small molecule, typically water, during the polymerization process, while addition polymers form without the loss of any small molecules.

What are the two types of condensation polymers discussed in the script?

-The two types of condensation polymers discussed are polyesters and polyamides.

What is the chemical structure that holds polyamides together?

-Polyamides are held together by amide links, which are formed when a carboxylic acid reacts with an amine.

How is nylon 6,6 formed in the script's example?

-Nylon 6,6 is formed by reacting hexane-1,6-diamine, which has an amine group on each side, with hexanedioic acid, which has a carboxylic acid at each end.

What is the common name for polyethylene terephthalate and what is it commonly used for?

-Polyethylene terephthalate is commonly known as PET and is used for making plastic drinks bottles.

What is the chemical reaction that forms polyesters?

-Polyesters are formed through the reaction of a carboxylic acid with an alcohol, resulting in ester links.

Which two molecules are used to form PET in the script's example?

-Benzene-1,4-dicarboxylic acid and ethane-1,2-diol are used to form PET.

What is the role of water in the formation of condensation polymers?

-Water is eliminated as a byproduct during the formation of condensation polymers.

What are some uses of nylon in the script's description?

-Nylon is used in the textile industry and in engineering applications where low friction is required, such as in bearings or bushes.

How are the long carbon chains in the molecules of condensation polymers simplified for visualization in the script?

-The long carbon chains are removed and replaced with rectangular blocks to simplify the visualization and focus on the functional groups involved in the reaction.

What is the significance of the ester link in the formation of polyesters?

-The ester link is significant as it holds the large polymer molecule together in polyesters, resulting from the reaction between a carboxylic acid and an alcohol.

Outlines

🧪 Formation and Uses of Condensation Polymers

This paragraph introduces the concept of condensation polymers, contrasting them with addition polymers where a byproduct is also formed during the reaction. It highlights the two main types of condensation polymers: polyesters and polyamides. The formation of polyamides, specifically nylon 6,6, is explained through the reaction between hexane-1,6-diamine and hexanedioic acid, resulting in a polymer held together by amide links. The paragraph also mentions the applications of nylon in the textile industry and engineering, particularly for its low-friction properties.

🔍 The Structure and Synthesis of Polyamides

This section delves deeper into the synthesis of polyamides, illustrating the reaction between a carboxylic acid and an amine to form an amide link. It simplifies the complex molecular structures by using rectangular blocks to represent the functional groups involved in the reaction. The process results in the elimination of water and the formation of a large polymer molecule, which is then discussed in the context of its various uses, especially in applications requiring structural integrity and low friction.

📦 Polyester Formation: From Molecules to Plastics and Fabrics

The paragraph focuses on the formation of polyesters, specifically polyethylene terephthalate (PET), through the esterification reaction between a carboxylic acid and an alcohol. Similar to polyamides, the complex molecular structures are simplified for clarity. The ester links that form between the molecules are highlighted, along with the release of water as a byproduct. The uses of PET in creating plastic bottles and the broader application of polyester in clothing fabrics are also discussed.

Mindmap

Keywords

💡Condensation Polymers

💡Polyamides

💡Nylon 6,6

💡Amide Link

💡Polyesters

💡Ester Link

💡Polyethylene Terephthalate (PET)

💡Condensation Polymerization

💡Hexane-1,6-Diamine

💡Hexanedioic Acid

💡Benzene-1,4-Dicarboxylic Acid

💡Ethane-1,2-Diol

Highlights

Condensation polymers form with the elimination of a small molecule, typically water.

Polyesters and polyamides are two main types of condensation polymers.

Polyamides, like nylon, are formed through the reaction of a carboxylic acid and an amine.

Nylon 6,6 is created by reacting hexane-1,6-diamine with hexanedioic acid.

The formation of polyamides involves the creation of amide links and the release of water.

Nylon has applications in the textile industry and as a structural material in engineering.

Polyesters are formed through the reaction of an alcohol with a carboxylic acid to create ester links.

Polyethylene terephthalate (PET) is an example of a polyester formed from Benzene-1,4-dicarboxylic acid and ethane-1,2-diol.

The formation of polyesters also results in the release of water.

PET is commonly used for making plastic drink bottles.

Polyesters are also used to produce fabric for clothing.

Condensation polymerization involves monomers that react to form a polymer and a byproduct.

The structural representation of polymers can be simplified using rectangular blocks to illustrate functional groups.

Nylon's structural soundness makes it suitable for applications requiring low friction, such as in bearings or bushes.

Understanding the chemical processes behind polymer formation is crucial for their practical applications.

The tutorial aims to provide a clear understanding of what condensation polymers are and their uses.

Transcripts

Browse More Related Video

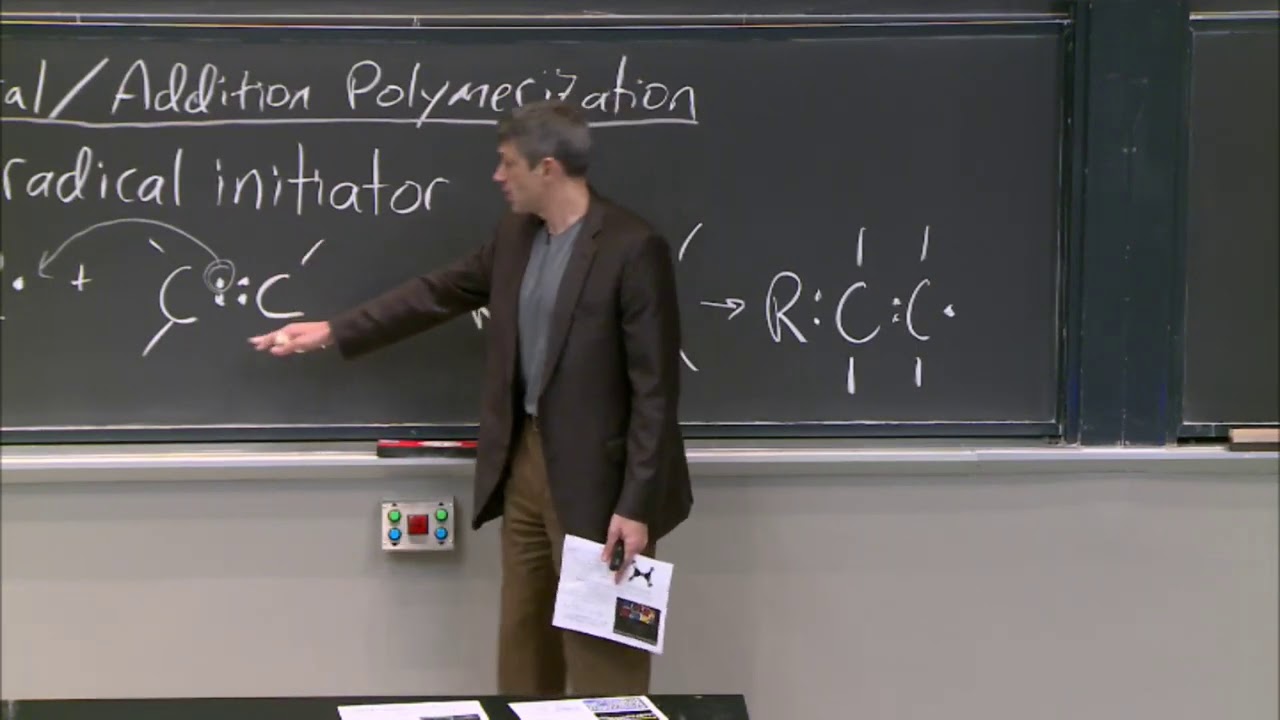

32. Polymers I (Intro to Solid-State Chemistry)

Polymer Chemistry: Crash Course Organic Chemistry #35

GCSE Chemistry - Condensation Polymers (Polyesters) #60

What Is Thermosetting and Thermosoftening Polymers | Organic Chemistry | Chemistry | FuseSchool

Polymers: Crash Course Chemistry #45

Polymer | Condensation polymers| polyester | engineering chemistry | mohan dangi

5.0 / 5 (0 votes)

Thanks for rating: