This Is How We Make Our Own SUGAR!

TLDRThis video script offers a detailed guide to transforming maple syrup into maple sugar, a versatile ingredient that can replace regular sugar in various recipes. It highlights the simplicity of the process, which involves minimal additional steps beyond syrup production. The script walks viewers through the stages of syrup preparation, including using an RO system to purify sap, and then heating the syrup to specific temperatures to crystallize it into sugar. The result is a natural, nutrient-rich alternative to commercial sugar, with the added benefit of a distinct maple flavor.

Takeaways

- 🌳 The process of making maple sugar involves turning maple syrup into a sugar form, which can replace regular sugar in various recipes.

- 🍂 Maple sugar can be produced from the syrup collected during different seasons, which results in varying colors and flavors.

- 📏 To ensure the maple syrup is ready for sugar conversion, it should reach a specific sugar content measured by a refractometer, ideally between 66 and 67 Brix.

- 🔥 The conversion from syrup to sugar requires heating the syrup to a high temperature to evaporate the moisture and allow crystallization.

- 👨🍳 Using a hand mixer can help in the process of turning the heated syrup into sugar, making it easier than traditional manual stirring methods.

- 🍽️ Maple sugar is versatile and can be used in baking, wine making, curing meats, and as a seasoning, replacing the need for other sugars.

- 🚫 The process of making maple sugar does not require filtering out all the sugar sand or impurities present in the syrup, preserving some of the tree's nutrients.

- 🌡️ A thermometer is essential to monitor the temperature during the sugar-making process, aiming for around 130 degrees Celsius (or 266 degrees Fahrenheit).

- 🧼 To control foaming during boiling, a small amount of fat or oil can be added to the syrup, such as olive oil or butter.

- 🍬 Once the syrup reaches the right temperature and consistency, it can be transferred to another container to cool and harden into sugar.

- 🗑️ Cleanup after making maple sugar is relatively easy, as the residual sugar can be dissolved with hot water, requiring minimal scrubbing.

Q & A

What is the main purpose of the video script?

-The main purpose of the video script is to demonstrate the process of making maple sugar from maple syrup, including the steps from tree to the final product, and to show the versatility of using maple sugar in various recipes.

How does maple sugar differ from regular sugar in terms of usage?

-Maple sugar can be used in any way regular sugar is used, with the only difference being an extra step to convert the syrup into sugar. It simplifies the process of incorporating it into recipes that call for sugar, eliminating the need to adjust for syrup.

What are the benefits of making maple sugar instead of just using maple syrup?

-Making maple sugar saves the effort of filtering out sugar sand or other impurities that come with the syrup, which also retains some of the tree's goodness and nutrients. It's also easier to use in recipes that call for sugar.

How do the colors of different batches of maple syrup indicate their properties?

-The color of the maple syrup indicates the time of the season it was made. Early season syrup is lighter with a higher sugar content, less caramelization, and less bacteria, while late season syrup is darker and has a more pronounced maple flavor.

What is the importance of using a thermometer when making maple sugar?

-A thermometer is crucial for ensuring the syrup reaches the correct temperature for sugar formation. It helps in removing as much moisture as possible, which is essential for the syrup to crystallize and turn into sugar.

What is the role of a hydrometer or refractometer in maple syrup production?

-A hydrometer or refractometer is used to measure the sugar content of the maple syrup. For the syrup to be shelf-stable, it needs to be between 66 and 67 Brix, which ensures it won't spoil.

How does the use of an RO (Reverse Osmosis) system benefit the maple syrup production process?

-An RO system removes some of the pure water from the sap before it goes into the evaporator, concentrating the sap. This reduces the boiling time, the amount of wood used, and overall time spent in production.

What method is used to control the foaming of the syrup while boiling to make sugar?

-To control foaming, a small amount of fat or oil, such as lard, butter, or vegetable oil, can be added to the boiling syrup. This helps to reduce the foam and prevent it from overflowing.

What tool is recommended for mixing the syrup as it turns into sugar?

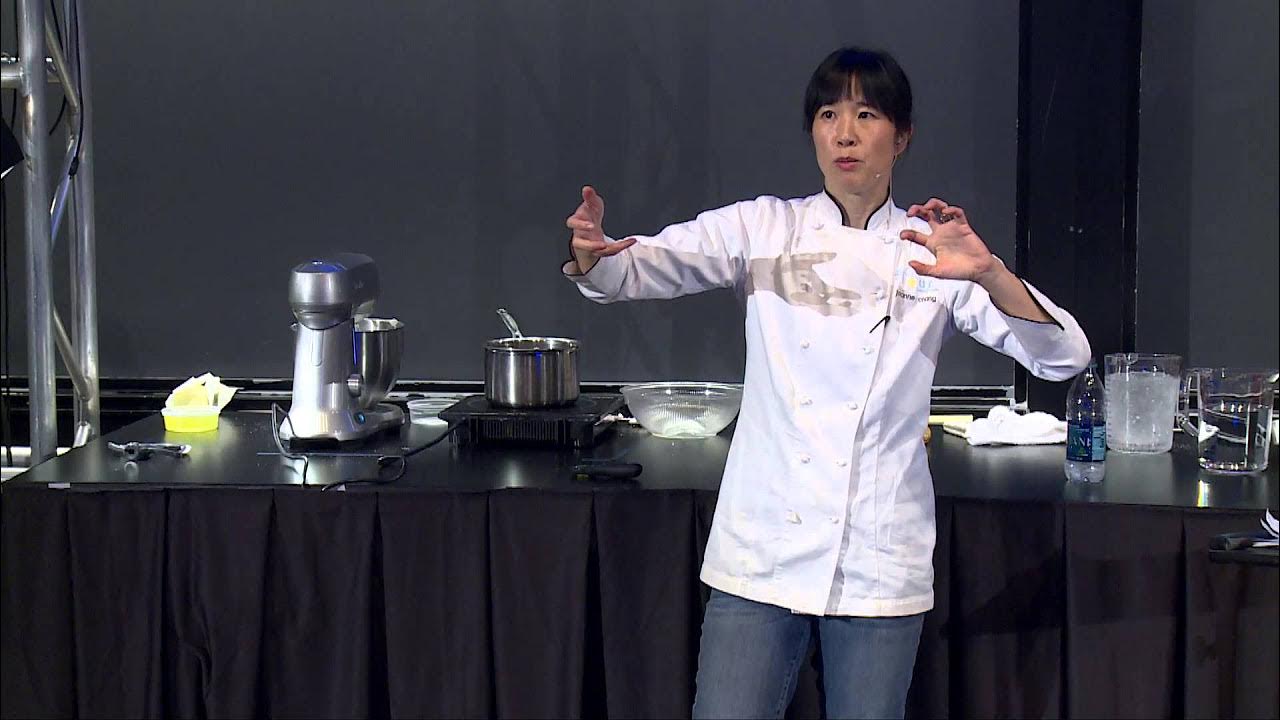

-An electric hand mixer is recommended for mixing the syrup as it turns into sugar. It's less labor-intensive than stirring by hand and less likely to damage kitchen appliances like a KitchenAid mixer.

How can the maple sugar made from different syrups be distinguished in terms of color and flavor?

-Maple sugar made from lighter syrup will look more like white sugar and be very sweet, while sugar made from darker syrup will resemble brown sugar and have a more pronounced maple flavor.

What is the final step to ensure the maple sugar is ready for storage?

-The final step is to ensure the maple sugar is completely moisture-free by spreading it out and allowing it to dry further. Once dry, it can be stored indefinitely in a suitable container.

What environmental and social impacts are associated with white sugar that the script suggests maple sugar could help mitigate?

-The script implies that white sugar production has significant social and environmental impacts, which are often overlooked. By using maple sugar produced in one's backyard, one can reduce reliance on conventional sugar and potentially lessen these impacts.

Outlines

🍁 Maple Sugar Production Journey

This paragraph introduces the process of making maple sugar from the sap of maple trees. It explains that maple sugar is a versatile ingredient that can replace regular sugar in any recipe. The speaker shares that they use maple sugar for a variety of culinary purposes, including baking, wine making, and curing meats. The process involves an extra step beyond making maple syrup, which includes not filtering out all the sugar sand or nighter, thus preserving the nutrients and flavor. The video also touches on the different colors of syrup produced at various stages of the season, indicating differences in sugar content, flavor, and bacteria levels.

🌡️ Transforming Syrup into Sugar

The second paragraph delves into the technical aspects of turning maple syrup into sugar. It emphasizes the importance of using a calibrated thermometer to ensure the syrup reaches the correct temperature for sugar formation. The speaker describes the process of reheating the syrup to a temperature of around 130 degrees Celsius (or 266 degrees Fahrenheit) to initiate the crystallization process. The paragraph also mentions the use of an RO system to filter sap more efficiently and the use of fats or oils to control foaming during boiling. The goal is to remove as much moisture as possible to achieve a crystallized sugar product.

🍬 The Art of Sugar Crystallization

This paragraph describes the hands-on process of crystallizing maple syrup into sugar. It details the use of an electric hand mixer to mix the syrup as it reaches the appropriate temperature, causing it to foam and release moisture. The speaker notes the visual and sensory changes that occur as the syrup transforms, including the lightening of color and the thickening of the mixture. The paragraph also covers the cleanup process, which involves using hot water to dissolve any remaining sugar in the pot, and the final steps of transferring the crystallized sugar to a container for cooling and further processing.

🥣 From Syrup to Granulated Sugar

The final paragraph focuses on the finishing stages of maple sugar production. It explains how to transfer the cooled sugar into a coffee grinder to achieve a finer consistency suitable for baking and other culinary uses. The speaker contrasts the appearance and flavor of sugar made from lighter versus darker syrup, noting that darker sugar has a more pronounced maple flavor. The paragraph concludes with practical advice on storing the sugar to ensure it remains moisture-free and the potential environmental benefits of using homemade maple sugar as an alternative to traditional white sugar.

Mindmap

Keywords

💡Maple Sugar

💡Maple Syrup

💡Sugar Content

💡Reverse Osmosis (RO) System

💡Evaporator

💡Sugar Sand

💡Caramelization

💡Hydrated

💡Foaming

💡Crystallization

💡Sieve

Highlights

Maple sugar can be used as a direct substitute for regular sugar in any recipe.

Making maple sugar involves only one extra step beyond making maple syrup.

Maple sugar retains the beneficial nutrients and flavors from the maple tree.

The process of making maple sugar is simplified by not needing to filter out all sugar sand.

Different seasons yield maple syrup with varying colors and flavors.

Using a refractometer ensures the maple syrup has the correct sugar content for shelf stability.

The transition from syrup to sugar is marked by a change in color and texture.

A reverse osmosis system is used to filter sap, reducing boiling time and resource use.

SimPure sponsored the video and provided the RO system for maple syrup production.

A thermometer is crucial for accurately monitoring the temperature during the sugar-making process.

Foaming during boiling can be controlled with a few drops of oil or by rimming the pot with butter.

An electric hand mixer is used to transform the syrup into sugar.

The sugar-making process releases steam, indicating the evaporation of remaining moisture.

Maple sugar made from lighter syrup has a sweeter taste, while darker syrup produces sugar with a more pronounced maple flavor.

Maple sugar can be stored indefinitely if kept moisture-free.

Cleaning the pot used for sugar-making is simple with hot water, as the sugar dissolves easily.

Making maple sugar at home can help reduce reliance on traditional white sugar with environmental impacts.

The video demonstrates a sustainable and enjoyable method of producing maple sugar.

Transcripts

5.0 / 5 (0 votes)

Thanks for rating: