Liquid Piston Rotary Engine - Yet Another Engine That Changes Everything?

TLDRThe video script discusses the innovative Liquid Piston X-engine, which, unlike traditional Wankel engines, features a unique design that allows for a higher compression ratio and the potential for a pistonless Atkinson cycle. The X-engine promises high power density, reduced emissions, and less vibration, making it suitable for niche applications like UAVs and military power generators. However, challenges remain with its torque, emissions, and longevity, limiting its widespread use in conventional automotive and mass production markets.

Takeaways

- 🔧 The Liquid Piston X-engine is a unique engine design that features a fundamentally different thermodynamic cycle, architecture, and operation compared to traditional Wankel engines.

- 💡 The X-engine overcomes the compression ratio limit of Wankel engines, allowing for higher efficiency and making a diesel or compression ignition version possible.

- 🚀 The X-engine's inverted geometry enables a pistonless implementation of the Atkinson cycle, which improves efficiency by having a longer expansion stroke than compression stroke.

- 🌬️ The engine's design results in three combustion events per rotor revolution, similar to a Wankel, but with a fundamentally different operation due to its geometry.

- 🌡️ The X-engine's design reduces energy waste and heat in the exhaust, contributing to lower noise and cooler operation compared to conventional engines.

- 🏎️ Despite its innovative design, the X-engine faces challenges with apex seals and lubrication, which are critical issues for its longevity and mass production viability.

- 🛠️ The X-engine's assembly process is complex and requires skill, similar to the Wankel engine, which may hinder its mass production and affordability.

- 🚫 The engine's thermal efficiency and torque output are lower than conventional engines, making it less suitable for road-legal vehicle applications and range extenders.

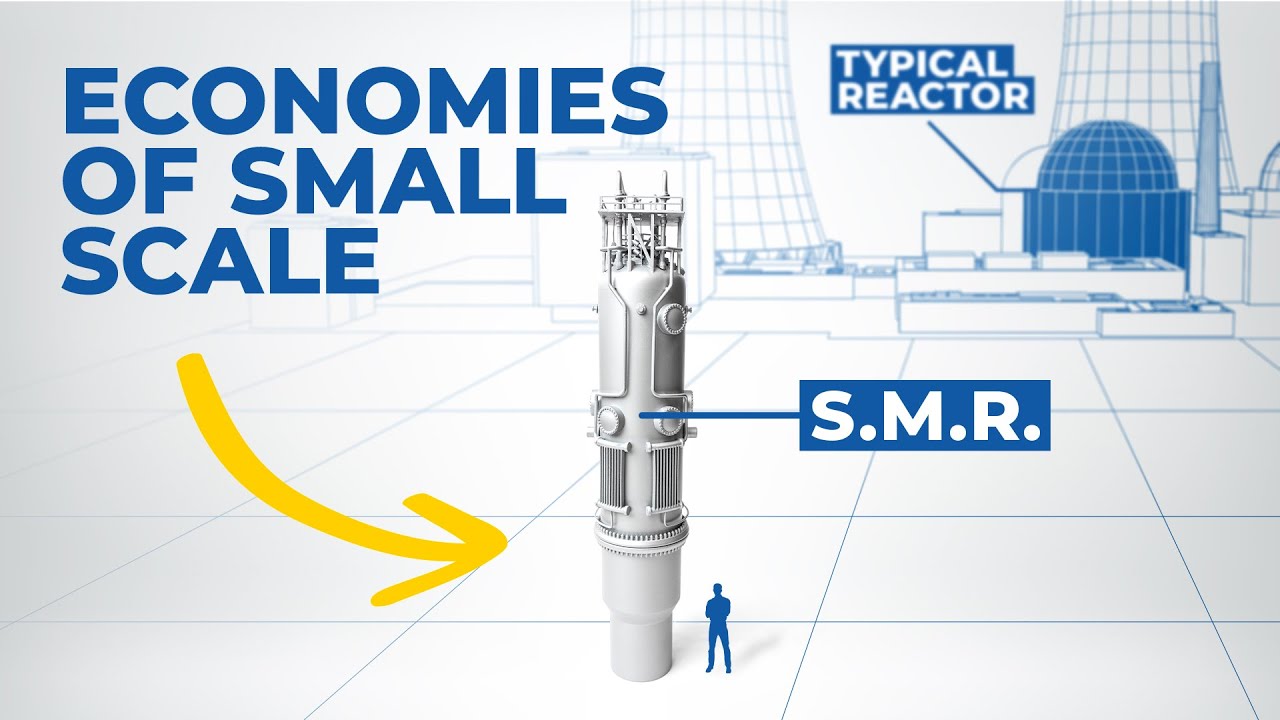

- 💰 The X-engine's potential market applications are niche-specific, such as UAVs, generators, and military use, due to its lightweight, compact, and high power density characteristics.

- 🛠️ The Liquid Piston company has received a multi-million dollar grant from the U.S. Army to further develop the X-engine for use in power generators, highlighting its potential in specific applications.

- 🌐 The X-engine represents an innovative approach to engine design, but its widespread application is limited by current technological challenges and market factors.

Q & A

What is the primary difference between a Rotary Wankel engine and a Liquid Piston X-engine?

-The primary difference lies in their design and operation. While both engines have a rotor that spins and creates three combustion events per rotation, the Liquid Piston X-engine features a fundamentally different thermodynamic cycle, architecture, and operation. It overcomes the compression ratio limit of the Wankel engine and can run on diesel or other heavy fuels due to its unique geometry.

How does the Liquid Piston X-engine address the issue of compression ratio in the Wankel engine?

-The Liquid Piston X-engine's geometry does not have a compression ratio limit, unlike the Wankel engine, which is limited to around 12:1. This allows the X-engine to potentially achieve higher efficiency and makes it feasible to create a diesel or compression ignition version of the engine.

What is the significance of the Atkinson cycle in the context of the Liquid Piston X-engine?

-The X-engine implements a pistonless version of the Atkinson cycle, which is called the 'High Efficiency Hybrid Cycle' by Liquid Piston. This allows for a longer expansion stroke compared to the compression stroke, improving efficiency by reducing energy losses during the combustion process.

How does the Liquid Piston X-engine reduce noise and vibrations?

-The X-engine reduces noise and vibrations by not having cams or valves and by having a simple design with fewer moving parts. Additionally, the absence of reciprocating pistons minimizes vibration.

What are the power density figures for the Liquid Piston X-engine compared to a conventional piston engine?

-The Liquid Piston X-engine has a power density of 1.2 horsepower per pound, which is significantly higher than a conventional 70cc piston-based scooter engine that has a power density of 0.68 horsepower per pound.

What are some potential applications for the Liquid Piston X-engine?

-Potential applications for the X-engine include generators, auxiliary power units, UAVs, range extenders, handheld power equipment, mopeds, small vehicles, lawn and garden equipment, and robotics.

Why might the Liquid Piston X-engine face challenges in mass production and widespread market entry?

-The X-engine faces challenges due to its complex multi-seal arrangement, which is not conducive to mass production. Additionally, issues with lubrication and apex seals may impact the engine's longevity and emissions, making it less suitable for road-legal vehicle applications and other markets with strict emission standards.

What is the expected lifespan of the Liquid Piston X-engine between rebuilds?

-The expected lifespan of both the spark ignition and compression ignition versions of the X-engine is 1,000 hours between rebuilds, which is significantly lower compared to conventional engines.

How does the Liquid Piston X-engine address the issue of lubricating apex seals?

-The X-engine uses stationary apex seals that can be lubricated directly through access points in the engine housing. Liquid Piston claims this method allows for better lubrication of the apex seals and oil consumption comparable to a four-stroke piston engine.

What are the thermal efficiency figures for the Liquid Piston X-engine?

-The thermal efficiency for the spark ignition version of the X-engine is 25%, and for the compression ignition version, it is 45%.

Why is the Liquid Piston X-engine unsuitable for variable valve timing?

-The X-engine is unsuitable for variable valve timing because it lacks a cam and valves. The only potential variable valve arrangement it could use is similar to the power valve found in two-stroke engines, but this is not as effective or flexible as modern variable valve lift and timing systems found in most piston-based engines.

Outlines

🚗 Introduction to Rotary Wankel and Liquid Piston Engines

This paragraph introduces the rotary Wankel engine, characterized by a triangular rotor spinning inside an epitrochoidal housing, and the Liquid Piston Engine, which features an epitrochoidal rotor within a triangular housing. The discussion includes a comparison between these engines and traditional piston engines, highlighting the unique features and potential benefits of the Liquid Piston design. The Wankel engine's operation is explained, including the intake, compression, combustion, and exhaust processes, and how the Liquid Piston engine, despite its name, does not use liquid pistons but has a fundamentally different thermodynamic cycle, architecture, and operation. The paragraph also mentions the limitations of the Wankel engine, particularly its maximum compression ratio of 12:1, which affects its efficiency and the feasibility of creating a diesel version.

🌟 Advantages and Innovations of the Liquid Piston X-Engine

This paragraph delves into the advantages of the Liquid Piston X-engine, which lacks a compression ratio limit, making it possible to run on diesel or other heavy fuels. It also enables the implementation of a pistonless Atkinson cycle, which improves efficiency by having a longer expansion stroke than the compression stroke. The X-engine's unique geometry allows for a larger combustion volume compared to the compression volume, leading to reduced energy losses and better efficiency. The paragraph also discusses the engine's reduced noise and vibration, high power density, and potential applications in generators, UAVs, and other small vehicles. However, it also raises concerns about the engine's market viability outside of niche applications due to unresolved issues with apex seals and other challenges.

🛠️ Challenges and Limitations of the Liquid Piston Engine

This paragraph addresses the challenges and limitations of the Liquid Piston engine, including its apex seals and the complexity of reducing by-blow. It also discusses the engine's multi-seal arrangement, which complicates mass production and longevity. Lubrication issues are highlighted, particularly the inability to use an oil bath or pressurized oil for the crankshaft, leading to the use of sealed bearings that are less effective for longevity. The expected lifespan of the engine between rebuilds is also discussed, with the X-engine having a significantly shorter lifespan compared to conventional engines. Additionally, the paragraph touches on the engine's thermal efficiency, which, while decent, does not surpass that of inexpensive mass-produced piston engines.

🏎️ Specific Applications and Future Prospects for the X-Engine

The final paragraph discusses specific applications where the X-engine could excel, such as for the US Army as lightweight, compact power generators, and for UAVs due to its power density, small size, and quiet operation. It also addresses the engine's limitations in terms of torque, emissions, and suitability for mass production. The paragraph concludes that while the X-engine is an innovative and interesting design with potential for niche applications, it is unlikely to see widespread use in the automotive or mass market due to its current limitations. The video ends with a reflection on the importance of such innovations for the future of engine design, despite their potential drawbacks.

Mindmap

Keywords

💡Rotary Wankel Engine

💡Liquid Piston Engine

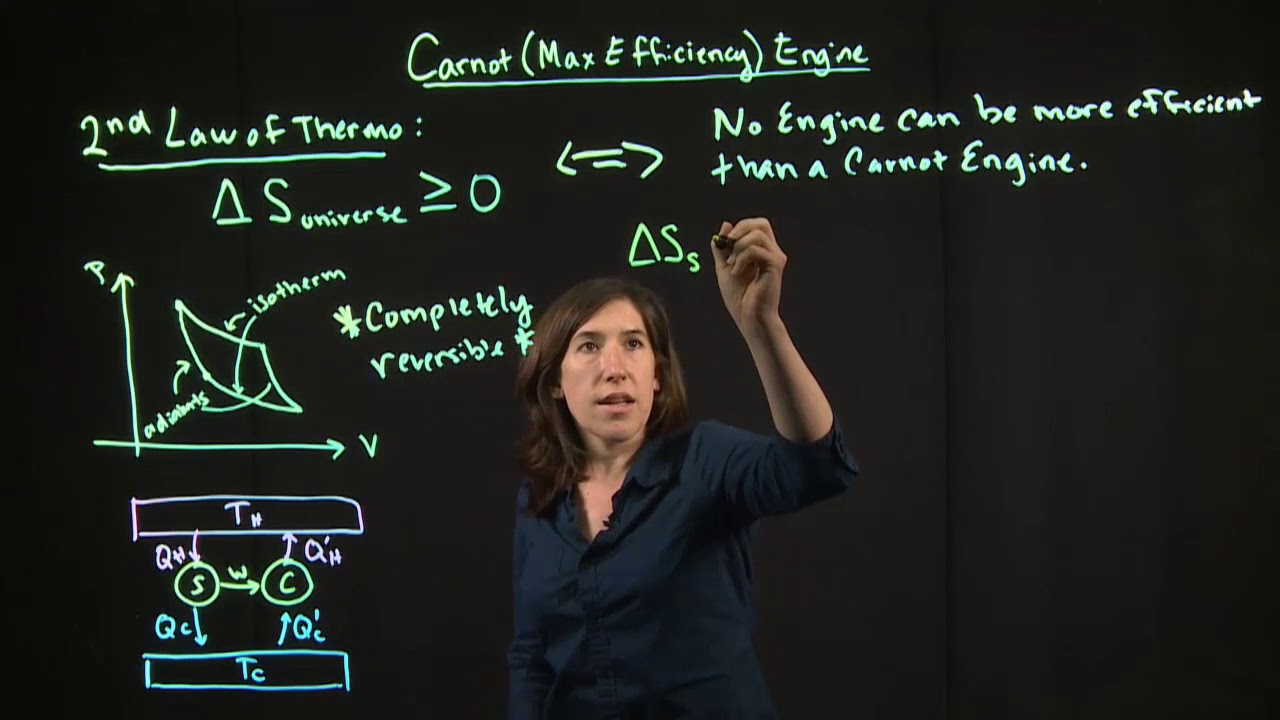

💡Thermodynamic Cycle

💡Compression Ratio

💡Atkinson Cycle

💡Power Density

💡Apex Seals

💡Lubrication

💡Emissions

💡Torque

💡Variable Valve Timing

Highlights

The Liquid Piston X-engine is introduced as a fundamentally different engine from the traditional Wankel engine, with a unique thermodynamic cycle, architecture, and operation.

The X-engine features an epitrochoidal rotor spinning inside a triangular housing, contrasting with the Wankel engine's triangular rotor in an epitrochoidal housing.

The X-engine overcomes the Wankel engine's inherent limitation of a compression ratio limit of around 12:1, allowing for higher efficiency and the possibility of a diesel version.

Liquid Piston's design enables a pistonless implementation of the Atkinson cycle, which is not achievable by traditional piston engines without complex systems.

The X-engine's unique geometry results in a combustion volume larger than the compression volume, leading to reduced energy losses and improved efficiency.

The X-engine's simple design with fewer moving parts and no cams or valves results in high power density and reduced noise and vibrations.

The X-Mini prototype of the X-engine boasts an impressive power density of 1.2 horsepower per pound, outperforming conventional piston-based engines.

Despite its innovative design, the X-engine still relies on apex seals, which have not been fully resolved and may limit its mass production and longevity.

Liquid Piston claims a 35% reduction in by-blow compared to a conventional Wankel engine, with the potential for up to 65% reduction.

The X-engine's crankshaft design precludes it from using journal or ball bearings, which are essential for longevity, resulting in the use of sealed bearings instead.

The X-engine is expected to last only 1,000 hours between rebuilds, significantly less than conventional engines.

The X-engine's thermal efficiency figures are 25% for the spark ignition version and 45% for the compression ignition version, which, while decent, do not outperform mass-production ready piston engines.

The X-engine's low torque output makes it unsuitable for road legal vehicle applications and range extenders.

The X-engine's lack of variable valve timing capability limits its effectiveness and flexibility compared to modern piston-based engines with advanced valve systems.

Despite its limitations, the X-engine's lightweight, compact, and power-dense design makes it attractive for niche applications such as UAVs and military power generators.

The US Army has granted Liquid Piston millions for further development of these engines, highlighting their potential in specific military applications.

The X-engine's innovative design, while not suitable for widespread application, showcases the potential for creative engineering solutions in niche markets.

Transcripts

5.0 / 5 (0 votes)

Thanks for rating: