Extraction Of Aluminium Using Electrolysis | Environmental Chemistry | FuseSchool

TLDRThis video delves into the process of aluminium extraction via electrolysis, highlighting its significance despite the high costs involved. Aluminium, abundant yet expensive due to its energy-intensive extraction, is valued for its conductivity, low density, and resistance to corrosion. The script explains the use of bauxite, which is purified to yield aluminium oxide, subsequently dissolved in molten cryolite to lower the melting point. The electrolysis process involves graphite-coated steel cathodes and graphite anodes, where aluminium forms at the cathode and oxygen, reacting with carbon, forms carbon dioxide at the anode, necessitating regular replacement. The video underscores the environmental and economic challenges of aluminium production.

Takeaways

- 🌏 Aluminium is the most abundant metal on Earth, but its extraction is expensive due to high electricity usage.

- 🚀 Aluminium's properties, such as good heat and electricity conductivity, low density, and resistance to corrosion, make it ideal for various applications like aeroplanes, drinks cans, cables, and cookware.

- 💎 The primary ore of aluminium is bauxite, which is purified to produce aluminium oxide, a white powder.

- 🔋 The extraction of aluminium is done through a process called electrolysis, which requires the aluminium oxide to be in a molten state for ion movement.

- 🔥 To lower the high melting point of aluminium oxide, it is dissolved in molten cryolite, a compound with a lower melting point.

- 🛠️ The electrolysis setup includes a steel case coated with graphite as the cathode and graphite anodes immersed in the molten cryolite.

- 🔩 During electrolysis, aluminium forms at the cathode as aluminium ions gain electrons, and oxygen forms at the anodes where it reacts with carbon to produce carbon dioxide.

- ⏳ The anodes wear away due to the reaction with oxygen and need to be replaced regularly, adding to the cost of aluminium extraction.

- 💰 The overall reaction for aluminium extraction is the conversion of aluminium oxide to aluminium and oxygen, highlighting the energy-intensive nature of the process.

- 🔍 The script emphasizes the importance of understanding the reactions at the electrodes, where reduction and oxidation occur, respectively.

- 👍 The video encourages viewers to engage by liking, subscribing, and commenting if they have questions, and also promotes a related app.

Q & A

Why is aluminium considered expensive to produce?

-Aluminium is considered expensive to produce because it requires a significant amount of electricity to extract it from its ore, bauxite, through the process of electrolysis.

What are some of the unique properties of aluminium that make it useful in various applications?

-Aluminium has several unique properties, including good heat and electricity conductivity, low density, and resistance to corrosion, which make it useful in applications such as aeroplanes, drinks cans, electricity cables, and cooking pans.

What is the primary ore from which aluminium is extracted?

-The primary ore from which aluminium is extracted is called bauxite.

How is aluminium oxide obtained from bauxite?

-Bauxite is purified to yield aluminium oxide, which is a white powder.

What is the role of cryolite in the extraction of aluminium?

-Cryolite is used to dissolve aluminium oxide because it has a lower melting point than aluminium oxide, which helps to reduce the costs of the extraction process by lowering the temperature required to make the aluminium oxide molten.

Why is the steel case in the electrolysis process coated with graphite?

-The steel case is coated with graphite to provide the negative cathode in the electrolysis process.

What happens to the aluminium at the cathode during the electrolysis process?

-When the battery is turned on and electricity flows, the aluminium from the aluminium oxide in the cryolite forms at the negative cathode and sinks to the bottom of the tank, where it can be tapped off as pure liquid metal.

Why does the positive anode need to be replaced regularly during the electrolysis of aluminium?

-The positive anode needs to be replaced regularly because the oxygen from the aluminium oxide reacts with the carbon of the graphite anode, forming carbon dioxide and wearing away the anode.

What is the overall chemical reaction for the extraction of aluminium via electrolysis?

-The overall chemical reaction for the extraction of aluminium via electrolysis is the conversion of aluminium oxide to aluminium plus oxygen.

What occurs at the negative cathode during the electrolysis process?

-At the negative cathode, aluminium ions from the molten aluminium oxide cryolite solution are reduced, meaning they gain electrons, forming aluminium metal.

What occurs at the positive anode during the electrolysis process?

-At the positive anode, oxygen ions are oxidized, meaning they lose electrons, and react with carbon to make carbon dioxide.

Outlines

🌟 Aluminum Extraction Through Electrolysis

This paragraph introduces the process of extracting aluminum, the most abundant metal on Earth, despite its high cost due to the significant electricity consumption required. Aluminum's properties, such as its conductivity, low density, and resistance to corrosion, make it ideal for various applications, including aircraft, beverage cans, electrical cables, and cookware. The script explains that aluminum ore, known as bauxite, is purified to produce aluminum oxide, which is then reduced to aluminum through electrolysis. The use of molten cryolite is highlighted as a method to lower the melting point of aluminum oxide, thus reducing extraction costs. The paragraph also describes the electrolysis setup, including the graphite-coated steel case serving as the cathode and the graphite anodes, and outlines the reactions occurring at the electrodes, resulting in the formation of aluminum at the cathode and carbon dioxide at the anodes. The summary emphasizes the high cost of aluminum extraction due to the consumption of electricity and the need for regular anode replacement.

Mindmap

Keywords

💡Aluminium

💡Bauxite

💡Aluminium Oxide

💡Electrolysis

💡Cryolite

💡Graphite

💡Cathode

💡Anode

💡Reduction

💡Oxidation

💡Carbon Dioxide

Highlights

Aluminium is the most abundant metal on Earth but is expensive due to high electricity consumption in its extraction.

Aluminium's properties, such as heat and electricity conductivity, low density, and resistance to corrosion, make it ideal for various applications like aeroplanes, drinks cans, electricity cables, and cooking pans.

The aluminium ore, bauxite, is purified to produce aluminium oxide, a white powder.

Aluminium is extracted from aluminium oxide through a process of electrolysis.

A refresher on electrolysis is suggested for those who need to understand the process used in aluminium extraction.

Aluminium oxide must be molten for electrolysis, which is achieved by dissolving it in molten cryolite, a compound with a lower melting point.

Cryolite reduces costs in aluminium extraction due to its lower melting point compared to aluminium oxide.

The electrolysis setup includes a steel case coated with graphite as the cathode and graphite anodes immersed in the molten cryolite.

During electrolysis, aluminium forms at the cathode and sinks due to its higher density compared to the aluminium cryolite solution.

The oxygen from the aluminium oxide reacts with the carbon of the anode to form carbon dioxide, leading to the anode's regular replacement.

The overall chemical reaction in the extraction process is the conversion of aluminium oxide to aluminium and oxygen.

At the cathode, aluminium ions are reduced, gaining electrons from the molten aluminium oxide cryolite solution.

At the anode, oxygen ions are oxidized, losing electrons and reacting with carbon to produce carbon dioxide.

The anode's gradual wear due to the reaction with oxygen from the solution is a factor in the high cost of aluminium extraction.

Aluminium extraction is very expensive due to the significant amount of electricity required for the process.

The video encourages viewers to like, subscribe, and comment with any questions, and to check out their fusible app.

Transcripts

Browse More Related Video

Extraction of aluminium from bauxite - IGCSE metals chemistry

GCSE Chemistry Revision "Electrolysis of Aluminium Oxide"

The Extraction of Aluminium - Electrolysis (GCSE Chemistry)

Purifying Copper | Reactions | Chemistry | FuseSchool

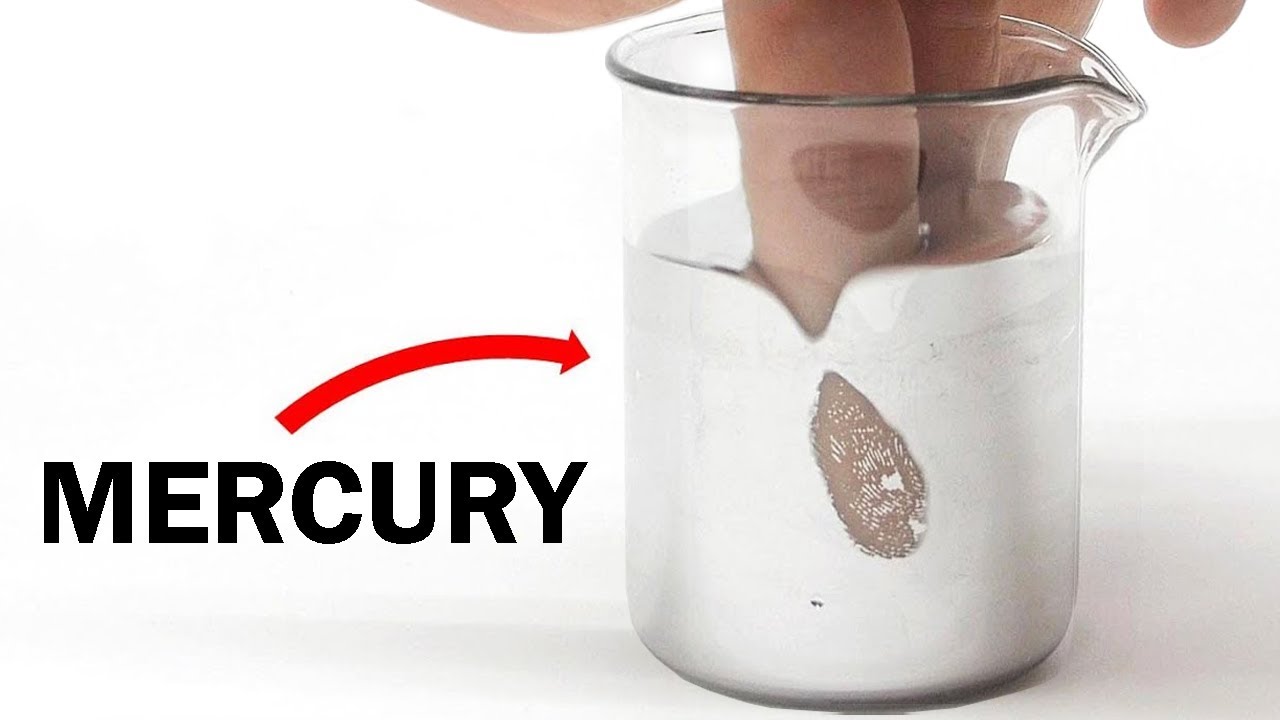

All about Mercury, the Liquid Metal | Element Series

Electrolysis of Water - Electrochemistry

5.0 / 5 (0 votes)

Thanks for rating: